IJCRR - 6(2), January, 2014

Pages: 01-05

Print Article

Download XML Download PDF

STUDIES ON MICROBIOLOGICAL QUALITY OF IDLI FORTIFICATION WITH WHEY PROTEIN CONCENTRATES

Author: Alka Yadav, Ranu Prasad

Category: General Sciences

Abstract:The present study was undertaken with the objectives to determine the shelf life of the prepared product and to estimate the cost of the production. Four different ratio of WPC @ 5%, 10%, 15%, 20% and different holding times 10, 15, 20, 25 minutes for fermentation of batter were used in the present study. Product was tested for yeast and mould count, standard plate count, coliform count and cost of the product was also worked out for different treatment combinations. The data obtained during investigation were statistically analysed by using two way classification and Critical Difference (CD) technique between treatments. The highest average yeast and mould count/gm of idli samples 37.83 was recorded on day fifteen. The highest average SPC/103gm of idli samples 52.61 was recorded on day fifteen. The coliform count is negative which means that strict hygienic practice was observed during preparation of idli. The highest cost of the idli sample T4H3 is Rs. 26.70 as compared to the other treatments. Result revealed that the microbial analysis of the prepared product is equally good, free from yeast and mould, standard plate count and coliform and is safe for consumption.

Keywords: batter, fermentation, Whey Protein Concentrate, fortification, idli

Full Text:

INTRODUCTION

Idli a fermented, steam cooked breakfast food is popular all over India. Extremely scrumptious, light, fluffy and nutritious and it is an ideal breakfast dish. Made of rice and urad daal, making idli is not difficult at all, though its preparation takes a little time as the batter for idli requires fermentation. As it is a steamed food with minimum oil and no spices, it is very healthy food for all age group peoples (Blandino et al., 2003). Idli is also known as “Rice cake” is a traditional food of India. Rava idli or rave idli is a variation of idli, made with Rava / sooji instead of the usual rice and urad daal. The fermentation process breaks down the starches so that they are more readily metabolized by the body. The term semolina is derived from the Italian word “Semola” which is derived from the ancient Latin Simila, meaning “Flour”. Semolina is made from hard durum wheat. It is the starchy endosperm part only which is separated from the bran and the wheat germ and then milled into flour. In south India, semolina is used to make savory foods like rava dosa, upma and puddings like “Kesari” or “Sheera”. In North India it is used for sweets such as “Suji halwa”. Whey Protein Concentrate (WPC) is a co- product of the cheese making process and it is pure, all natural, high quality product that contains little to no fat, lactose or cholesterol. Whey protein concentrate (WPC) is a white to light cream coloured product with a blend, clean flavour and it is as a source of amino acids and its effect on reducing the risks of diseases such as heart disease, cancer and diabetes (Krissansen, 2007). Whey protein concentrate (WPC) is an abundant source of branched chain amino acids (BCAAs), which are used to fuel working muscles and stimulate protein synthesis. It contains more leucine then milk protein, egg protein and soy protein and it stabilize blood glucose levels by slowing the absorption of glucose into the bloodstream (Patel, 2003).

MATERIALS AND METHODS

Preparation of idli Whey protein concentrate (WPC) was purchased from Mahan Protein Limited in New Delhi for each replications. Other ingredients such as Semolina, Eno powder and salt were collected from local market of Allahabad. Four different ratios of whey protein concentrate (5%,10%,15%,20%) were used for making idli and four different holding times (10,15,20,25 minutes) were used in the present experimental work. Idli prepared from different treatment combinations were compared with each other.

Microbial analysis Yeast and mould count

It was determined as per the procedure laid down in IS: 1479, Part- III (1962) of Manual in Dairy Bacteriology, ICAR publication

Standard plate count (SPC)

It was determined as per the procedure laid down in IS: 1479, Part- III (1962) of Manual in Dairy Bacteriology, ICAR publication.

Coliform count

It was determined as per the procedure laid down in IS: 1479, Part- III (1962) of Manual in Dairy Bacteriology, ICAR publication.

Determination of cost of the product

The cost of the prepared product was calculated at the prevailing prices of raw materials purchased from the local market of Allahabad

Statistical analysis

The data obtained for various parameters were analyzed statistically by using two way classification and Critical Difference (CD) technique (Imran and Coover, 1983).

RESULTS AND DISCUSSION

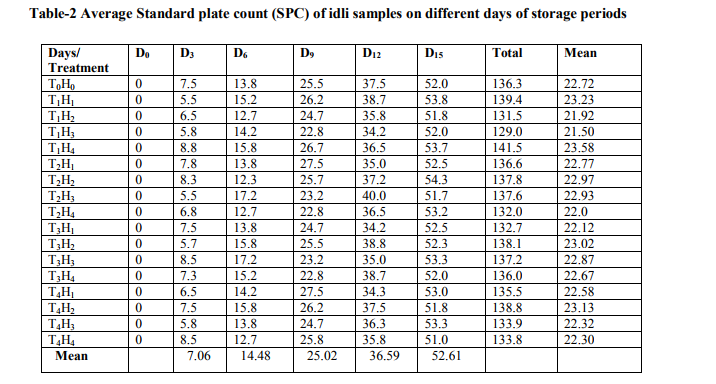

Yeast and mould count Therefore, it is concluded that the highest average yeast and mould count/gm of idli samples 37.83 was recorded on day fifteen followed by day twelve (25.58), day nine (16.49) and day six (8.22). The lowest average yeast and mould count/gm of idli samples 2.83 was recorded on day third. This result indicates that the yeast and mould count/gm of idli samples was obtained less than the range indicated 100 cfu/gm (B.I. Standards) till day fifteen, so prepared idli could be stored for fifteen days under refrigerator temperature. As the time period in number of days increases the yeast and mould count also increases.

Standard plate count (SPC)

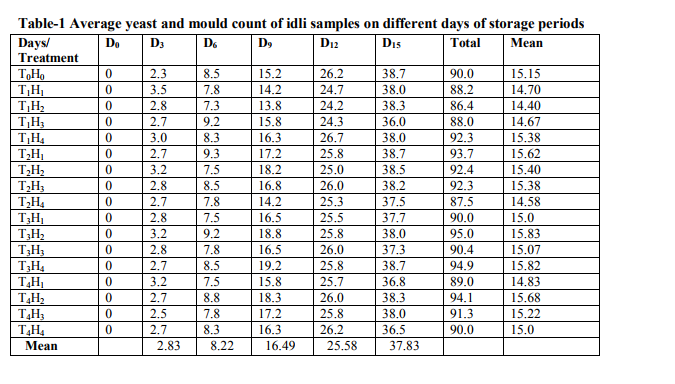

Therefore, it is concluded that the highest average SPC/103 gm of idli samples 52.61 was recorded on day fifteen followed by day twelve (36.59), day nine (25.02) and day six (14.8). The lowest average count for SPC/103 gm of idli samples 7.06 was recorded on day third. This result indicates that the standard plate count/gm of idli samples was obtained less than the range indicated 30 × 103 cfu/gm (B.I. Standards) till day nine, so from this point of view prepared idli could be stored for nine days under refrigerator temperature. As the time period in number of days increases the standard plate count also increases.

Coliform count

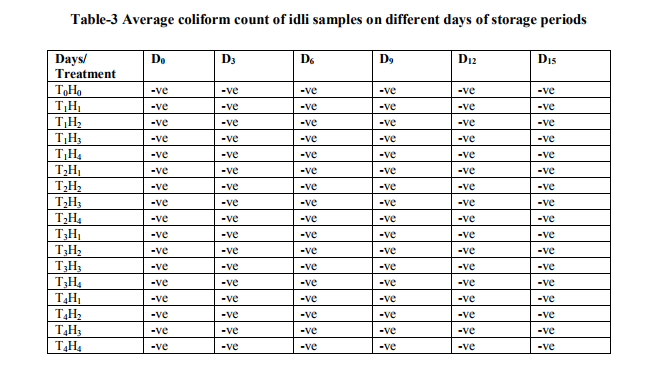

Table–3 shows that the coliform negative which means that strict hygienic practice was observed during preparation of idli fortification with whey protein concentrate.

Cost of the product

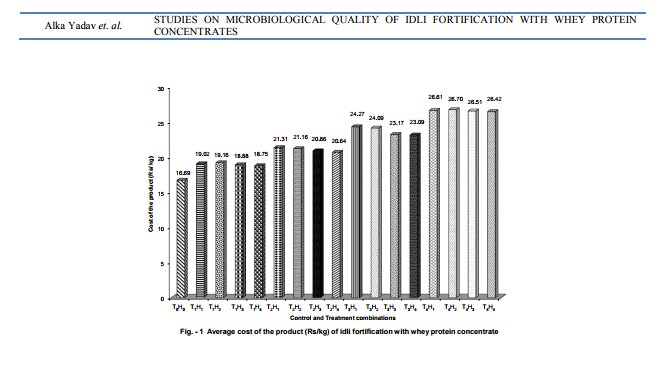

Figure – 1 shows that the highest total cost of idli sample in Rs. 26.70 was obtained in T4H2 sample and the lowest cost of idli sample in Rs.16.69 was recorded for T0H0 sample. The cost of the ingredient is very important factor besides other factors in determining the cost of the production. It is considered as a basis for price fixation and determining the profit. The price of a product is dependent on the cost of production.

CONCLUSION

From the findings of this study, can be concluded that the microbial analysis of the prepared product is equally good, free from yeast and mould, standard plate count and coliform and is safe for consumption. The highest cost of the idli sample T4H3 is Rs. 26.70 as compared to the other treatments combinations. Its cost is low and the lower cost of the product will be more affordable by a larger segment of the population. Storage of idli at refrigerator temperature will increase its shelf life.

References:

REFERENCES

1. Blandino, A.; Al – Aseeri, M.E.; Pandiella, S.S.; Cantero, D. and Webb, C. (2003). Cereal based fermented foods and beverages. International J. of Food Research, 36: 527 – 543.

2. Krissansen, G.W. (2007). Emerging health properties of whey proteins and their clinical implications. J. Am Coll Nutr., 26 (6): 713 – 723.

3. Imran, R.L. and Coover, W.B. (1983). A modern approach to statistics. New York: John willy and sons inc, 497.

4. Indian Standards Specification: 4883, (1968). Bureau of Indian Standards for dairy products. Indian Standards Institution, Manak Bhavan, New Delhi.

5. Indian Standards: (Part 3). (1947). Manual in dairy bacteriology. ICAR publication 1972.

6. Patel, G.R. (2003). Research and product development needs of dairy sector. 55 (3): 56 – 62.

|

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License