IJCRR - 6(20), October, 2014

Pages: 29-34

Date of Publication: 20-Oct-2014

Print Article

Download XML Download PDF

STANDARDIZATION OF CEREAL AND PSEUDOCEREAL FLOUR FOR PITTU PREPARATION

Author: Kalai R., R. Jagan Mohan

Category: Healthcare

Abstract:The cereal and pseudo-cereal such as raw brown rice, parboiled brown rice, Italian millet and samai were selected for pittu preparation. In the preparation of cereal and pseudo-cereal flour the moisture percentage after washing with respect to parboiled brown rice was comparatively higher moisture percentage of 11.88 % and 11.46 % after shade drying. The shade dried cereal and pseudo-cereal were powdered using plate mill. The cereal and pseudo-cereal flour obtained from the different mesh sizes was observed (BSS 30, 60, 85, 100 and >100) and BSS 60 and 85 used to prepare pittu was organoleptically evaluated. The study revealed that the sieve size BSS 60 for pittu preparation found to possess the highest overall sensory acceptability score compared to other sieve size. The standardized steaming time for cereal pittu control, raw brown rice, parboiled brown rice and samai was 20 minutes. The pittu made from Italian millet was 25 minutes.

Keywords: Cereal and pseudo-cereal, Raw brown rice, Parboiled brown rice, Italian millet, Samai, Sieve retention, pittu

Full Text:

INTRODUCTION

Cereal grains are consumed as staple foods throughout the world (Khatkar et. al., 2009). India is the second largest rice producing country in the world next to China. The production alone is not enough to meet growing demand of the quality rice and its products. The newer techniques of processing are equally important to maintain quality of the milled rice and produce high quality products. In recent years, a number of processing technologies have been developed for rice milling and its products (Patil and Singh, 2008). The coarse cereals contain tough and fibrous seed coat, and the seed coat contains polyphenols, phytate and astringent components. Because of these, the food items prepared from their whole meal have low consumer appeal. Processing (dehusk and polishing) of these cereals has overcome these disadvantages and improves their overall acceptability and nutritional quality (Desikachar, 1980; Klopfenstein, 1991 and Dendy, 1995). Rice is one of the important cereals in the world and largest consumed calorie source among the food grains. With a per capita availability of 73.8 kg it meets 31% of the total caloric requirement of the population. It is commonly used as milled (white) rice produced by removing the hull and bran layer of the rough rice kernel (paddy) (Perdon et al., 2001). In India 65% of rice consumed is after parboiling. Millet is being cultivated in the temperate zones of Asia, China, East Asia and also in the tropics of the continent; India, Indochina and Malaysia. Little millet is cooked like rice and sometimes it is also milled and baked. The protein content of this grain is 7.7% (German Wikipedia; Heywood, 1978). Foxtail millet ranks second in the total world production of millets and it continues to have an important place in the field of agriculture all over the world providing approximately six million tons of food to millions of people, mainly on poor or marginal soils in the Southern Europe and in the temperate subtropical and tropical Asia (Marathee, 2003). In light of the above literature, the present study was designed “Standardization of cereal and pseudocereal flour for pittu preparation” with the following objectives:

1. To study the characteristics of selected cereal and pseudo-cereal pittu flour.

2. To develop and standardization of cereal and pseudo-cereal pittu

MATERIALS AND METHODS

MATERIALS

The raw materials selected for this study was Paddy (Var. ADT 36), Italian millet, Samai (Panicum miliare), raw milled rice and salt which were purchased from the local departmental stores.

Equipment used

Petit Balance, Top pan balance, Hot air oven, Muffle Furnace, Plate mill, Sieve, and Utensil were used for this study.

METHODS

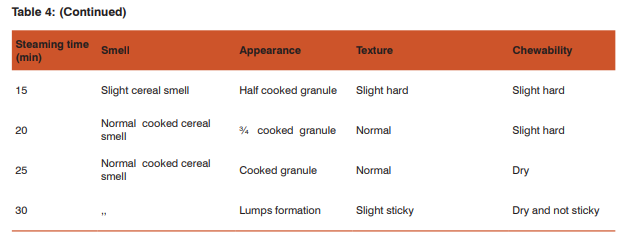

1. Processing of cereal and pseudo-cereal flour The raw rice, raw brown rice, parboiled brown rice, Italian millet and samai were separately washed thoroughly with cold water, then drained the water and shade dried for 20 min. The shade dried cereals are powdered using plate mill. Then the flour was passed through the British Standard Sieves (BSS) of different mesh size (BSS 30, 60, 85, 100 and above BSS 100). 1.1 Moisture content of cereal and pseudo-cereal during flour preparation The raw rice, raw brown rice, parboiled brown rice, Italian millet and samai were washed thoroughly in cold water, drained the water and shade dried for 20 minutes. The initial moisture, after washing and drying was estimated. 1.2 preparation of cereal and pseudo-cereal flour in plate mill The shade dried cereals was passed through the plate mill for size reduction, adjusted to the grain ¾ size, to prevent heat damage of the grain. The milled flour was sieved through British Standard Sieves of different mesh sizes BSS 30, 60, 85, 100 and >100 The BSS 30 sieve retention flour was again passed to the plate mill adjusted to grain 2 /4 size, then sieved through BSS 30. The different mesh size sieved flour was collected. The same procedure was followed one more time. 1.3 Selection of flour for pittu The cereal flour passed through BSS 30 sieve flour, suitable for the preparation of pittu, possessed granules of bigger size and cereal flour passed through sieves BSS 100 and > BSS 100 was fine in nature. So, the BSS 30, BSS 100 and > BSS 100 sieve flour was rejected for the preparation of pittu. The BSS 60 and BSS 85 sieve retention flour used to prepare pittu was organoleptically evaluated. From this BSS 60 sieve retention flour had the highest overall acceptability score compared to BSS 85. From the evaluation, for the preparation of pittu, BSS 60 sieve retention flour was selected for the study. 1.4 Physical characteristics of pittu in different steaming time Physical characteristics such as smell, appearance, texture and chewability of control, raw brown rice, parboiled brown rice, Italian millets and samai pittu in different steaming time was observed.

STATISTICAL ANALYSIS

The data collected from the various experiments were analysed, statistically, using mean and Standard deviation (SD) was used to compare the means. The one way analyses of variance with critical difference was used compare and determine moisture content and Size reduction characteristics of cereal and pseudo-cereal during flour preparation as per the methods described by Dhamu and Ramamoorthy, (2007).

RESULTS AND DISCUSSION

PROCESSING OF CEREAL AND PSEUDO-CEREAL FLOUR

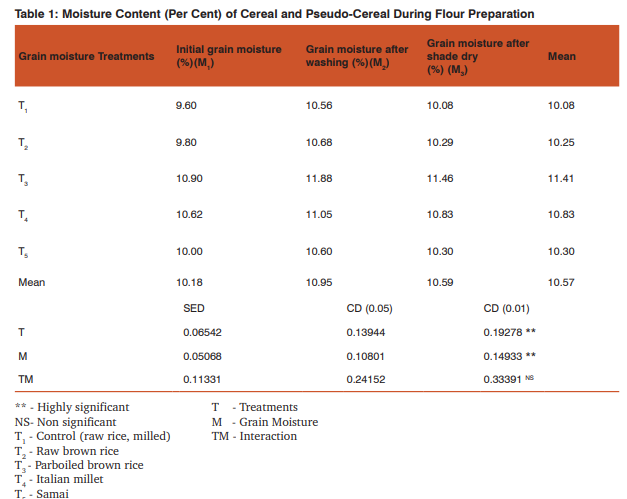

Moisture content of cereal and pseudo-cereal during flour preparation Moisture content of cereal during flour preparation is presented in Table 1. From the Table-1, the grain samples T1 - T5 ranged from a minimum of 9.60 % in control (T1 ) to a maximum of 10.90 % in (T3 ). The percentage of moisture changes after washing was found to be the maximum in T3 (11.88 %) followed by T4 (11.05 %) and T2 (10.68 %) whereas, minimum gain in moisture percentage was reported in the control (10.56 %) followed by T5 (10.60 %) compared to other cereals. The percentage of moisture content of the grain after shade drying was reported to be maximum in T3 (11.46 %) followed by T4 (10.83%) and T5 (10.30 %). The minimum value of 10.08 % was reported in control and followed by T2 (10.29 %). The statistical analysis revealed that the treatments of different cereals were highly significant with respect to percentage of moisture content. The different levels of moisture content of cereals, during cereal flour preparation, were also highly significant. Kebakile et al., (2007) reported grains with harder endosperms give higher flour yields than those with softer endosperms, the softer the grain, the more the meal was contaminated with bran; the harder the grain, the less germ was removed.

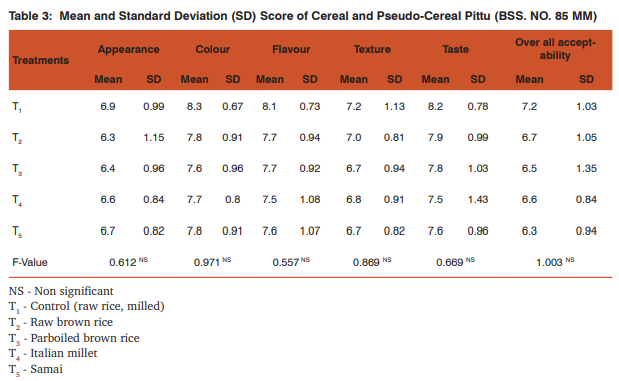

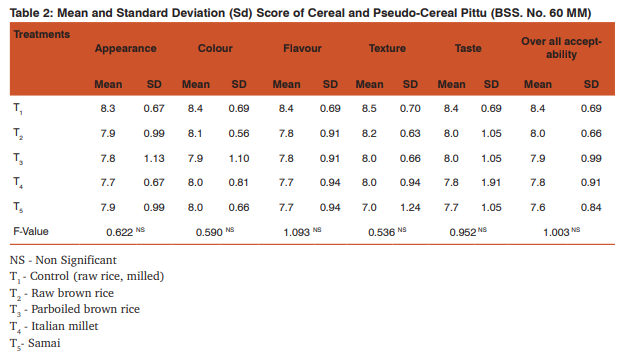

Selection of flour for pittu The BSS 60 and BSS 85 sieve retention flour used to prepare pittu was organoleptically evaluated and statistically analysed and presented in the Table-2 and Table-3. It was found that the BSS 60 sieve retention flour used to prepare pittu had the highest overall acceptability score compared to BSS 85. After the evaluation, the BSS 60 sieve retention flour was selected for the preparation of pittu in the study. The statistical analysis, namely one way analysis of variance for BSS 60 and BSS 85 flour pittu, with respect to various organoleptic characteristics such as appearance, colour, flavor, texture, taste and overall acceptability, was done. The results are furnished in Table-2 and Table-3.

Standardized steaming time for pittu

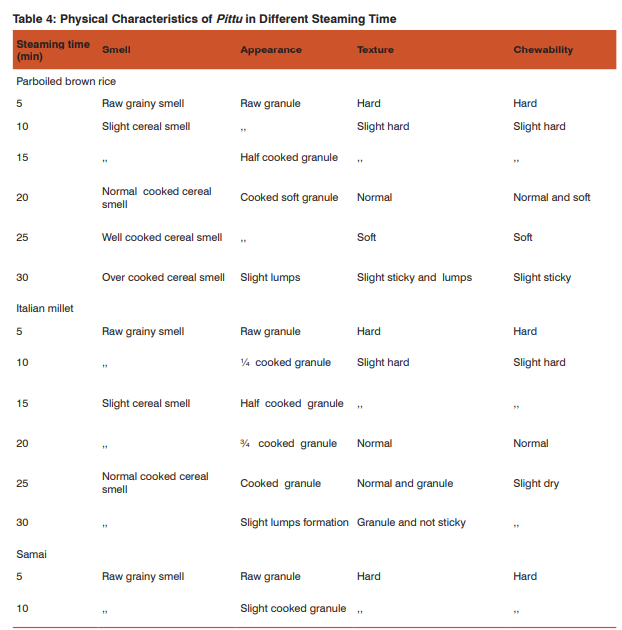

Physical characteristics of pittu in different steaming time are presented in table-4. Standardized steaming time for cereal pittu control, raw brown rice, parboiled brown rice and samai was 20 min. whereas for the Italian millet it was 25 min. Varadharaju et al., (2001) observed the cooking times of raw rice samples ranging between 22 and 25 min and those optimum parboiled samples ranging between 25.33 and 30.33 min. The increase of cooking time of the optimum parboiled rice over the raw rice was to the extent of 18 to 24%. The increase in the cooking time in the parboiled samples may be because of the low hydration capacity with temperatures above their gelatinization temperature.

SUMMARY

The selected cereal and pseudo-cereal percentage of moisture content after shade drying was higher compare to the initial moisture content of the grains. The cereal flour obtained from the mesh sizes (BSS 60 and 85) used to prepare pittu was organoleptically evaluated. From this evaluation, BSS 60 sieve retention flour used to prepare pittu had the highest overall acceptability score compared to BSS 85 sieve retention flour. Raw brown rice used to prepare pittu had a highly acceptable score when compared to control and other cereals. The statistical analysis revealed that the significant difference was observed in the texture among the treatments and organoleptic characteristics. Standardized pittu steaming time for control, raw brown rice and parboiled brown rice and samai was 20 min. The Italian millet took 25 min. It showed that the cereal containing high fibre required a longer steaming time.

CONCLUSION

The selected cereal and pseudo-cereal pittu, methods of preparation is easy and no special equipments are required for preparing the product. We can use these cereals in the place of polished, refined cereals. From the results of the study, it can be concluded that the selected cereal and pseudo-cereal are suitable for different age groups and more suitable for old age people

ACKNOWLEDGEMENT

Authors are extremely grateful to Dr. R. Jagan MOHAN, Associate professor and Head, Department of Food Product Development, Indian Institute of Crop Processing Technology, Thanjavur for his valuable and erudite guidance. Authors extend their sincere thanks to Dr. S.

Kalavathi, Principal, Rani Meyyammai College of Nursing, Annamalai University for her valuable suggestions. Authors also like to thank the Editors and Publishers of International Journal of Current Research and Review.

References:

Dendy, D.A.1995. Production and important of millets. In Sorghum and millets: Chemistry and Technology. Am. Assoc. Cereal Chemists, Inc. St. Paul, Minnesota, USA. p. 11-26.

Desikachar, H.S.R. 1980. Three decades of research on the processing and utilization of food grains. Journal of Food Science Technology. 17:24-32.

Dhamu, K.P and Ramamoorthy, K. 2007. Statistical methods. First edition, AGROBIOS Publishes, India. Heywood, V.H. 1978.

Blutenpflazen der welt. Based Boston – Stuttgart. Kebakile, M.M., Rooney, L.W. and Taylor, J.R.N. 2007.

Effects of hand pounding, abrasive decortications-hammer milling , roller milling and sorghum type on sorghum meal extraction and quality. Cereal Foods World. 52(3):129-137.

Khatkar, B.S., Anil Panghal. and Umed singh. 2009.

Applications of cereal in food processing. Indian Food Industry. p. 37. Klopfenstein, C.F., Leipold, H.W and Cecil, J.E. 1991.

Semi- wet milling of pearl millet for reduced goitrogenicity. Cereal chemistry. 68:177-179.

Marathee, J.P. 2003. “Advance in small millets”. In structure and characteristics of the world millet economy. Sixth Edition, Oxford and IBH Publishers, Co. Pvt., New Delhi. p. 159-178.

Patil, R.T and Singh, K.K. 2008. Innovations in rice processing. Agricultural Engineering Today. 32(4):13-15.

Perdon, A.A., Siebenmorgen, T.J., Mauromoustakos, A., Griffin, V.K and Johnson, E.R. 2001. Degree of milling effect on rice pasting properties. Cereal Chemistry.78:205–209.

Varadharaju, N., Sreenarayanan and Thayumanavan, B. 2001.

Effect of moisture content, temperature and contact time on milling and cooking qualities of rice in conduction parboiling. Journal of Food Science Technology. 38(5):509- 511.

|

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License