IJCRR - 7(12), June, 2015

Pages: 64-71

Print Article

Download XML Download PDF

SCREENING OF CLONES OF CASUARINA EQUISETIFOLIA FOR PULPING TRAITS USING

WOOD FIBRE CHARACTERISTICS

Author: Kannan C.S. Warrier, E.V. Anoop, B. Gurudev Singh

Category: Healthcare

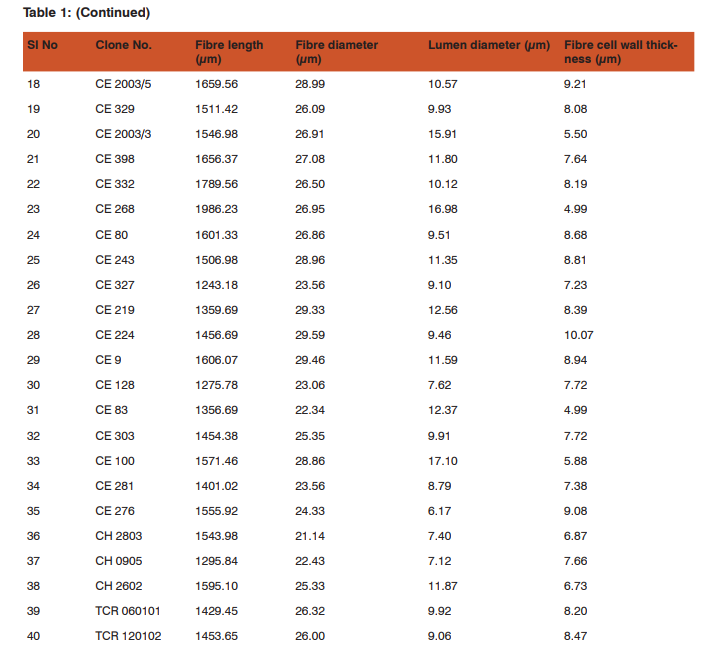

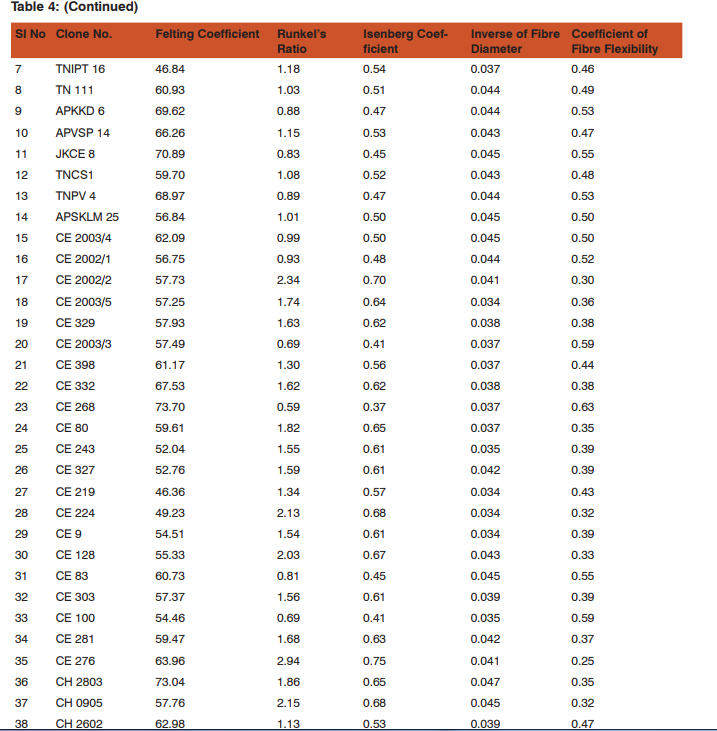

Abstract:Casuarina equisetifolia, a multipurpose tree species, is an important raw material for many major paper mills in India. Institute of Forest Genetics and Tree Breeding (IFGTB), Coimbatore, India is the focal point of Casuarina research in the country and has the largest germplasm assemblage in India. A study was undertaken at IFGTB to understand the wood fibre characteristics in select clones of this species as fibre characteristics like fibre length, fibre diameter, wall thickness and lumen diameter influence the quality of pulp and paper products. Wood samples collected from 43 clones and three seedling origin materials of C.

equisetifolia were subjected to various analyses. The maximum value for fibre length was registered by clone CE 268 (1986.23 \?m). Clone CE 327 recorded the minimum value (1243.18 \?m). Fibre diameter ranged from 21.14 (CH 2803) to 29.59 \?m (CE 224). Lumen diameter exhibited a wide variation between 6.17 to 17.10 \?m. Fibre cell wall thickness varied widely from 4.99 to 10.07 \?m. The minimum and maximum values were shown by clones CE 268 and CE 224 respectively. Ray height varied from 380.25 (CE 281) to 564.00 \?m (CE 2002/1). The values for ray width ranged between 23.56 to 43.23 \?m. Clones TNVM 3 and

TNPV 4 registered the minimum and maximum values respectively. With reference to ray frequency, clone CH 2803 registered the minimum value (20.60 no. per mm.). Clone CE 276 recorded the maximum (56.56 no. per mm.). Various rations like Felting coefficient, Coefficient of fibre flexibility, Runkel's ratio and Isenberg coefficient were also worked out. Clones with high Felting coefficient and Coefficient of fibre flexibility but low Runkel's ratio and Isenberg coefficient are ideal for pulp. In the present study it was observed that clones CE 83, CE 100, CE 268, CE 2003/3, CE 2003/4, TCR 120203, APKKD 6 and JKCE 8 in general were suitable for quality pulp production

Keywords: Casuarina, Pulping, Wood properties, Fibre characters

Full Text:

INTRODUCTION

Casuarina equisetifolia L. is a high value tree crop. It has a sustained market demand as scaffolding in building industry, cheap housing material, banana stakes and excellent fuelwood. It supports land reclamation and sand dune stabilization, and shelter belts along coastal tracts. This species is an important raw material for many major paper mills in India. These mills currently use more than 2 million tonnes of Casuarina wood per year. Pulp and Paper industries have undertaken various farm forestry programmes in which Casuarina is an important component. Realizing the potential of C. equisetifolia, systematic tree improvement programmes are being undertaken at the Institute of Forest Genetics and Tree Breeding (IFGTB), Coimbatore, Tamil Nadu for over two decades and is a focal point for Casuarina research in India. IFGTB has the largest germplasm of C. equisetifolia in the country. Apart from the growth characteristics, it is also equally important to understand the wood parameters. Fibre characteristics like fibre length, fibre diameter, wall thickness and lumen diameter influence the quality of pulp and paper products. These affect the bulk, burst, tear, fold and tensile strength of paper (Zobel, 1965). Therefore, a study was undertaken to understand the wood fibre characteristics in select clones of C. equisetifolia.

MATERIALS AND METHODS

Wood samples collected from 43 clones and three seedling origin materials of C. equisetifolia assembled by IFGTB were the experimental materials. Billets of 1 m length were cut from the basal position of one tree (ramet) each selected randomly from the clones. Transverse discs of 6 cm thickness were collected from the base, middle, and top positions of each billet. Wood shavings were taken from these discs and then maceration was carried out. Maceration of the wood samples was done using Jeffrey’s method (Sass, 1971). For maceration, Jeffrey’s solution was used and it was prepared by mixing equal volumes of 10% potassium dichromate and 10% nitric acid. Microscopic examination and quantification of macerated fibre were undertaken using an Image Analyser (Labomed-Digi 2). For vessel and ray morphology study, sections were taken from specimens of size less than 1 cm3 using microtomy. Sections were then stained with safranin for 5 minutes. Excess stain was removed by washing sections successively in 70, 90 and 95% ethanol solution. Thin sections were further dehydrated using acetone and then kept in xylene for two hours for getting rigidity. Sections taken out from xylene were permanently mounted on microscopic slides with cover slips using DPX.

RESULTS AND DISCUSSION

The primary results on wood analysis are presented in Tables 1 to 3. Table 4 shows the results on the various ratios worked out. The maximum value for fibre length was registered by clone CE 268 (1986.23 µm). Clone CE 327 recorded the minimum value (1243.18 µm). Out of the 46 tested materials, 19 measured a fibre length of more than 1500 µm. Good quality paper can be produced from long fibered woods. Fibre diameter ranged from 21.14 (CH 2803) to 29.59 µm (CE 224). Lumen diameter exhibited a wide variation between 6.17 to 17.10 µm. Fiber length, fibre diameter and lumen diameter are reported to be genetically controlled (Wheeler et al, 1965; Zhang and Jiang, 1998). Otegbeye and Kellison (1980) reported a heritability of 0.42 for fibre length, 0.82 for fibre diameter and 0.94 for wall thickness in Eucalyptus viminalis. Ratio of fibre length to fibre diameter is known as Felting coefficient. It affects the qualities of paper like ease of sheet formation, sheet smoothness and opacity. Higher the ratio, better the quality of paper. The maximum value was registered by clone CE 268 (73.70). Clone CE 219 recorded the minimum value of 43.36. Clones CE 83, TN 111, CE 398, CE 2003/4, CH 2602, TCR 120203, CE 276, APVSP 14, CE 332, TNPV 4, APKKD 6, JKCE 8 and CH 2803 registered higher values for this ratio. Fibre cell wall thickness varied widely from 4.99 to 10.07 µm. The minimum and maximum values were shown by clones CE 268 and CE 224. It showed a direct relationship with wood specific gravity. Though the quantity of pulp produced by the high dense wood would be high, the quality of the pulp would be poor due to the stiffness of fibres. Clones CE 100, TN 111, APSKLM 25, TNVM 2, CE 2003/3, CE 2003/4, CE 2002/1, APKKD 6, TNPV 4, JKCE 8, CE 83 and CE 268 showed lower values for fibre wall thickness (Table 1). The ratio of double wall thickness to lumen diameter is known as Runkel’s ratio. It also affects the quality of paper and pulp. Thick walled fibres are ausually stiff, resistant to beating and retain their rounded shape during sheet formation. This inhibits inter fiber bonding and the resulting fibers would be of low quality with poor printing surface. On the other hand, thin walled fibres bend easily and collapse upon pulping and provide a large area for inter fibre bonding (Kumar, 2001). Clones CE 268, CE 100, CE 2003/3, CE 83, JKCE 8, APKKD 6, TNPV 4, CE 2002/1, TNVM 2 and CE 2003/4 registered lower values for Runkel’s ratio. The values ranged from 0.59 (CE 268) to 2.94 (CE 276). The results could be obtained from Table 4. The ratio of double wall thickness to fibre diameter, known as Isenberg coefficient, influences the pulping qualities in several ways. It determines the degree of flexibility and collapse of fibers, both of which control the degree of conformability within the paper sheet and thus the numbers of inter fiber bonds. Generally lower the ratio, better the quality of paper (Kumar, 2001). In the present study, clones CE 268, CE 100, CE 2003/3, CE 83, JKCE 8, APKKD 6, TNPV 4, CE 2002/1, TNVM 2, CE 2003/4, TCR 120203 and APSKLM 25 exhibited lower values for this ratio (Table 4). Clone CE 268 registered the lowest value (0.37) while clone CE 276 estimated the highest (0.75). Coefficient of fibre flexibility is the ratio of lumen diameter to fiber diameter and it influences the flexibility of fibres. Generally, a higher ratio indicates better flexibility of fibres (Kumar, 2001). Clones APSKLM 25, TCR 120203, CE 2003/4, TNVM 2, CE 2002/1, TNPV 4, APKKD 6, JKCE 8, CE 83, CE 2003/3, CE 100 and CE 268 recorded higher values for coefficient of fibre flexibility. The values ranged between 0.25 (CE 276) and 0.63 (CE 268). The results could be obtained from Table 4. The inverse of fibre diameter is usually taken as a measure of wood density. It varied from 0.034 in clones CE 224, CE 9, CE 219 and CE 2003/5 to 0.047 in clone CH 2803. High dense wood is generally indicated by a lower value (Table 4). Higher values for the ray parameters are not ideal for pulp production. Ray height varied from 380.25 (CE 281) to 564.00 µm (CE 2002/1). The values for ray width ranged between 23.56 to 43.23 µm. Clones TNVM 3 and TNPV 4 registered the minimum and maximum values respectively. With reference to ray frequency, clone CH 2803 registered the minimum value (20.60 no. per mm.). Clone CE 276 recorded the maximum (56.56 no. per mm.). Clones CH 3001, TNVM 3, CE 276, CH 2803, CE 398, CE 332, CE 268, CE 100, CE 281, CE 243, TN 111, CE 80, CH 0905, CE 303, APKKD 6, CE 224, CE 2003/5, CE 83, CE 2003/3, TNRM 8 and TCR 120203 exhibited lower values for the ray characteristics. The results are summarised in Table 3.

CONCLUSION

Clones with high Felting coefficient and Coefficient of fibre flexibility but low Runkel’s ratio and Isenberg coefficient are ideal for pulp (Kumar, 2001). In the present study it was observed that clones CE 83, CE 100, CE 268, CE 2003/3, CE 2003/4, TCR 120203, APKKD 6 and JKCE 8 in general were suitable for quality pulp production based on the above mentioned ratios.

ACKNOWLEDGEMENT

Authors are grateful for the funding support from the Indian Council for Forestry Research and Education. Authors acknowledge the immense help received from the scholars whose articles are cited and included in references of this manuscript. The authors are also grateful to authors / editors / publishers of all those articles, journals and books from where the literature for this article has been reviewed and discussed.

References:

1. Kumar A. Clonal variability in Eucalyptus tereticornis Sm. [Dissertation] Forest Research Institute Deemed University, Dehra Dun, India; 2001.

2. Otegbeye GO, Kellison RC. Genetics of wood and bark characteristics of Eucalyptus viminalis. Silvae Genet. 1980 29: 27-31.

3. Sass JE. Botanical microtechnique. The IOWA State Univ. Press, Ames, IOWA, 1971: 12-54.

4. Wheeler EY, Zobel BJ, Weeks, DL. Tracheid length and diameter variation in the bole of loblolly pine. Tappi 1965 49: 484-490.

5. Zhang SY, Jiang ZH. Variability of selected wood characteristics in 40 half-sib families of black spruce (Picea mariana). Wood Sci. and Tech. 1998 32: 71-82.

6. Zobel BJ. Inheritance of fiber characteristics and specific gravity in hardwoods - A review IUFRO Section 41 Meet Melbourne, Australia, 1965:13.

|

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License