IJCRR - 7(12), June, 2015

Pages: 52-59

Print Article

Download XML Download PDF

LOGISTICAL FACTORS INFLUENCING PORT PERFORMANCE A CASE OF KENYA PORTS AUTHORITY (KPA)

Author: William K. Ruto, Everlyn Datche

Category: Healthcare

Abstract:The port of Mombasa is run and managed by Kenya ports Authority, over the recent years the global maritime trade has been evolving rapidly. The surge in shipping traffic and cargo volumes especially on container traffic has placed the port with a huge responsibility to provide effective, efficient and reliable maritime service. The primary objective of this study aims to find out the logistical factors influencing port performance at the port of Mombasa. The study gave recommendations which can make the Port of Mombasa become more efficient and effective as Port of choice for East and Central Africa region. A primary data analysis which uses data gathered through interviews and secondary data analysis which involves the utilization of existing data collected from the existing documents, questionnaires and interviews shall be conducted within sampled and selected organizations which according to the researcher are likely to give a clear picture of the current logistical factors influencing

port performance in the port of Mombasa. The target population under study was 600 Port Stakeholders including at least 10 experts from the 6 different background or expertise in the transport sector including Kenya Revenue Authority, Container Freight Stations officials, Kenya Association of Manufacturers and shipping officials with a certain level of knowledge of the Port of Mombasa and comparative ports in the Maritime Industry such as Singapore Port, Port of Dar es Salaam etc. The study use both quantitative and qualitative data, tables, charts and graphs are be used to illustrate findings. A conclusion on port performance at the port Mombasa today and its future development is provided as recommendations.

Keywords: Logistical, Stakeholders, Cargo

Full Text:

INTRODUCTION

Kenya Ports Authority is the only mandated Government Agency authorized to operate all sea ports in Kenya. The port of Mombasa is the largest port in East Africa and is the gateway to East and Central Africa and plays a very important role in facilitating trade and development of the region. The port has strategic importance far beyond the borders of Kenya. As the largest port in East Africa, it is the main gateway for the import and export of goods not only for Kenya but also to countries of the East African Community, the Democratic Republic of Congo, southern Sudan and southern Ethiopia (KPA Container Freight Station Policy, 2014). The Port handles approximately 90% of Kenya external trade in terms of tonnage. Mombasa port has 17 deep water berths. Cargo traffic through Mombasa port is about 24 million tonnes in year 2014 including over a 1 million TEUs of container traffic. Kenya Ports Authority also operates two inland container depots in Nairobi and Kisumu, currently the port has employees about 7200 workers working in various department with nearly 60% working in operations departments who execute the core functions of the port in cargo handling, marine services and stevedoring. Kenya Ports Authority s strategy is to introduce private sector management and financing so as to improve the port’s performance, starting with the new container terminal under construction, conventional berths, oil terminals and marine craft, currently the port employs approximately 7200 Employees. (KPA Annual Bulletin of Statistic 2013) The port of Mombasa is currently among the fast growing ports in the world in terms of container handling trends following the recent infrastructure development undertaken by the government to expand the current container terminal. Global Maritime Transport has considerably changed in the last decade. Maritime Transport is growing at a high pace. Container traffic is the fastest growing segment of maritime transport. Shipping lines have invested in ever growing containerships in order to benefit fromeconomies of scale: the threshold of 10,000 TEUs per vessel was surpassed whereas, ten yearsago, the largest vessels had capacity of 4,400 TEUs (Panamax). As a result of increased competition, mergers and takeovers have taken place in the recent years to establish “mega-carriers”. This trend of larger ships will increase pressure for better port facilities and for significant improvement in port performance to achieve high productivity. In the last decade, after a period of liberalization, concentration has grown in the maritime transport industry as well as for port operators. The barrier at entry is becoming increasingly high in maritime transport since shipping lines have to invest in mega-container vessels, which may now cost more than 100 million US dollars. Containerization rate continues to grow at a high pace. (Pálsson. G, Alan H, and Raballand G (2007) As ports would be increasingly challenged by intensified traffic, greater ship size and transhipment growth, ports capacity may have to be expanded in the future. Larger ships are more demanding in terms of port installations. The ship to shore gantry cranes need to be sufficiently large to reach all the containers and sufficiently fast in operation for an acceptable ship turnaround time. (Drewry, 2006) The Port of Mombasa also has four container berths with a total length of 840 meters with additional combi berths 13 and 14 being converted to handle container operations whose total length is 355metres. Containerized cargo represents about 70% of the Port of Mombasa’s total cargo volume, and that volume is growing at around 12% per year. The Port of Mombasa Container Terminal began operating in 1979. (Master Plan Study of the Port of Mombasa, 2009).

The goal-setting theory

Goal-setting theory had been proposed by Edwin Locke in the year 1968. This theory suggests that the individual goals established by an employee play an important role in motivating him for superior performance. This is because the employees keep following their goals. If these goals are not achieved, they either improve their performance or modify the goals and make them more realistic. In case the performance improves it will result in achievement of the performance management system aims (Salaman et al, 2005). Expectancy theory had been proposed by Victor Vroom in 1964. This theory is based on the hypothesis that individuals adjust their behavior in the organization on the basis of anticipated satisfaction of valued goals set by them. The individuals modify their behavior in such a way which is most likely to lead them to attain these goals. This theory underlies the concept of performance management as it is believed that performance is influenced by the expectations concerning future events (Salaman et al, 2005). Banfield and Kay (2008) describe performance management as a framework in which performance by individuals can be directed, monitored and refined. They also view performance management as the process of creating a work environment or setting in which employees are enabled to perform to the best of their abilities. Despite the fact that the number of studies measuring ports performance is flourishing, several deficiencies still exist. The vast majority of the studies have a specific focus towards the assessment of operations productivity, in order to conclude on port efficiency. According to Mangan and Cunningham, it has been argued that improved performance is partly due to revised handling procedures and focused management strategies as a result of private participation. The Port of Rotterdam follows Singapore in port performance and efficiency ranking, with over six private container terminals within its boundaries, all of which compete openly - thereby placing emphasis on service and ship turnaround times. Again the argument holds true that those ports where private participation is encouraged in areas of cargo handling and port administration, enjoy greater service enhancements and ultimately draw long-term sustainable business opportunities (Mangan and Cunningham 2001: 54)

The Port Performance

Ports have traditionally evaluated their performance by comparing their actual and optimum throughputs (measured in tonnage or number of containers handled). If a port’s actual throughput approaches its optimum throughput over time, the conclusion is that its performance has improved over time. On the other hand when the port registers poor performance such as high container dwell time, threat of Vessel delay surcharge and worst still is the big ships avoiding the port. In the long run this renders transport from the port un-competitive by factual analysis. Crane productivity which is calculated per crane and can be expressed in gross and net values; Port Productivity, there are seven different productivity measures which terminal operators need to compute, although they may wish to include others for monitoring their productivity. These core productivity measures are: Ship productivity which is the broadest measures of shipproductivity relate container handling rates for a ship’s call to the time taken to service the vessel; Quay productivity which defines the relation between production and quay resources, the latter can be measured by defining, for a given unit time. Terminal area productivity which is similar to the quay productivity indicator is the measure of ‘terminal area productivity’ which applies to the entire terminal and expresses the ratio between terminal production and total terminal area for a given unit time; Equipment productivity is the value that is of interest is the number of container moves made per working hour, either for an individual machine or for the stock of a particular type of machine. The number of moves can be deduced from data collected; Labour productivity even with a high level of mechanization, labour costs still form a large part of total terminal costs and it is important to monitor labour well and know what the productivity per man-hour is over a measured period; Cost effectiveness this brings the all- important element of cost into the equation. Perhaps the simplest and most revealing measure of a terminal’s efficiency is the cost of handling its container traffic or throughput over a specified period, Port dwell time which refers to the time cargo spends within the port or its extension. To separate the components of cargo delays, Dwell time figures have become a major commercial instrument to attract cargo and generate revenues. Port authorities and container terminal operators have increasingly strong incentives to lower the real figure. The average or mean dwell time has usually been the main target indicator in the best performing ports worldwide. (Raballand et al, 2005).

Drivers of Port Performance

Productivity at the East African ports is affected by several factors, among them are: Equipment Utilization and Labor productivity; For Mombasa, labour productivity still remains low despite heavy investment in equipment modernization and infrastructure development over the past five years. For instance, ship to shore gantry cranes recorded an average 18 mph in Mombasa and 14 mph in Dar – es – Salaam against an internationally acceptable standard of 25 – 30 mph. It is evident that dock workers are not making the best use of the recently acquired modern and more efficient equipment. In order to improve berth productivity at Mombasa, some shipping lines have been forced to implement an independent bonus scheme for dock workers in order to improve vessel turnaround time. (Kenya Shipping Council, 2008) Optimal use of available Infrastructure; Recent infrastructure developments at Mombasa such as the new container terminal and a new berth have not necessarily resulted in improved productivity at the container terminal. There still exists poor yard planning and it is not easy for importers of bulk containers to trace their cargo easily. Poor traffic flow within the port area occasioned by poor gate operations has resulted in an increase in truck turnaround within the port area. Entry and exit is now taking as much as 6 hours. (Kenya Transport Association, 2008) Loading Point in efficiencies; when it comes to loading within the port, trucks are spending up to 6 hours to load for containerized cargo and 2 days for bulk and conventional cargo. For instance, most of the loading at the grain bulk handling facility happens at night when the customs department is closed and transporters have to wait until the following day to load. Traffic Congestion within Port Cities and Cities along the Transport Corridor; both the cities of Dar es salaam and Mombasa are heavily congested with huge volumes of truck traffic entering and leaving the ports. In Mombasa, the heavy traffic between the port exit gates and Mariakani means that trucks are spending as much as 6 hours to navigate through a 30KMs stretch, which ordinarily would take 30 minutes. The situation is compounded by narrow roads and single lane roads between Changamwe and Miritini. As for cities along the corridor, Nairobi and Eldoret and Kampala are the most notorious in terms of traffics congestion. Lack of bypass roads in these cities, coupled with single lane roads passing through Eldoret town mean that trucks are spending an average 5 hours to transit through these cities at peak hours. Such infrastructure constraints within the port area and major cities along the transport corridor are responsible for the long truck turnaround times recorded in this survey Delays related to delivery at destination points; it is taking up to two days for trucks to off load cargo at destination points. This is common for local and other transit cargo that is destined for bonded warehouses where importers have failed to fulfill their tax and regulatory obligations when cargo crosses borders and thus trucks experience unnecessary delays as they await customs clearance. (East Africa Logistics Performance Survey 2012)

Port Infrastructure

Container terminals are essential inter-modal transportation network which work under multiple operational objectives. The main one is to minimize ships turnaround time and subsequently maximize the terminal throughput. They can be achieved by efficient loading and discharging of ships. Therefore, accurate ship assignment is usually taken as the key performance measure for the operational efficiency of a terminal. Other effective parameters in efficiency of container ports that is the quay length of which leads to economies of scale on the ability to handle more containers per one ship within one quay.

Recognizing that the shipping industry is shifting towards large vessels that cannot come to the Port of Mombasa due to draught restrictions, Kenya Ports Authority embarked on capital dredging of the navigational channel and anchorage basins, maintenance dredging of areas in front of the existing berths, the same have resulted in bigger ships calling at the port of Mombasa from the previous 1500 TEUs to the current 4000 TEUS per ship. A fully integrated ICT Strategy has embraced an Enterprise Resource Planning (ERP) system, a Kilindini Water Front system and a Community Based System, all web enabled. The Enterprise Resource Programme system integrates all functions at the Port to provide on-line and real-time information hence assisting in making timely decisions. Benefits of the waterfront system include: Reduced Human intervention due to system controls that are based on authorization, Reduced cargo documentation processing duration, Reduced cargo dwell time from an average of 8 days to 5 days, Reduced port clearance time from 5.5 days to 3 days, Enhanced planning process both in the yard and on board ship, Easy access of statistical data for planning and decision making, Enhanced audit trails, hence minimized cargo pilferage at the port (Bandari Magazine, 2012). The Community Based System, commonly known as the National Single Window System currently on trial and sensitization to stakeholder is due for full implementation soon (2015). Funded by the World Bank, the system is a flexible automated information sharing resource that will eventually link the port community users via electronic means to allow secure exchange of authorized data between partners. The port of Mombasa has been facing major challenges with Kenya Revenue Authority’s Cammis System and Kenya Ports Authority’s Kwatos System. Kenya’s rail corridor is of strategic importance to the region. It is a common knowledge that Standard Gauge Railway (proposed) and launched recently by President Uhuru will handle over 22 Million tonnage of Cargo against the current Single Gauge handling only 1.2 Million tonnes (Kamau. M, 2014). Linking the port of Mombasa to Nairobi and continuing onward into Uganda, it is a key conduit for bulk freight, easing pressure and providing additional capacity along the northern corridor. Currently the cargo is mostly transported using the road (97%) and the rail (3%). The gate expansion by KPA has enable trucks hauling export/imports/empty containers within Mombasa depots/CFS’s faster turnaround than previous. Currently the trucks are able to make 6 trips per day unlike 1trip per day before the gate expansion. This enables the fluid movement of containers from the port and creation of more space for incoming containers.

Cargo Handling

Equipment Cargo handling equipment includes equipment used to move cargo to and from marine vessels, on-road trucks and yards. The equipment typically operates at marine terminals or at rail yards and not on public roadways or lands. Kenya Ports Authority inventory on cargo handling equipment includes 7 Ship to Shore Cranes, 57 Terminal Tractor, 5 Mobile cranes, 23 Forklifts among others. Beside the availability of equipment there are other silent features which have direct correlation with performance, motivation is one among them, this is evidence by the various ships categories calling at the port of Mombasa, those with Incentives/motivations yield better results than those without incentive from the same operators. Records show that none motivating ships makes 15 moves per hours whereas those with incentives making as high as 40 moves per hour. Ships planning also play an important role in measuring Vessel performance and the features which drives the performance are cargo handling equipment allocation to a particular ships such as the number of SSG, TT etc, this will enable the ship have a well coordinate flow of cargo discharge as well as cargo loading. With regard to East African ports, it is important to note that the efficiency of these ports and the entire logistics chain is not wholly dependent on the management structure or ports authorities –There exist a number of public and private sector players who have a role to play in the goods clearance process and the efficiency with which they execute their obligations plays a critical role in the overall efficiency of ports. Clearing and forwarding agents, shipping lines, transporters, revenue authorities, standards bodies, the police and inspection agencies among other entities have in one way or another been an impediment to the smooth clearance of goods. Cargo owners are not spared either, as their readiness to effectively and efficiently engage in international trade transactions has also affected the efficiency of the goods clearance process (Langat. G, 2013)

Yard Capacity

The yard operation is perhaps the busiest of all the activities in the terminal. The operation involves discharging of containers from the vessels, loading of containers onto vessels, shuffling of containers that are out of sequence, in the yard block, redistribution of containers to other blocks for more efficient loading onto the second vessels and inter-terminal haulage where containers are moved to other yards in another terminal. A container Yard Operators must plan to satisfy prompt accommodation of ships with minimum waiting time in port, and with maximum use of berth facilities. Somewhere between these opposing objectives each container port must reach a compromise, the number of berths which will achieve the most economical transfer of cargo between ships and shore.

The crucial terminal management problem is to optimize the balance between the ship owners who request quick service of their ships and economic use of allocated resources. Since both the container ships and the container port facilities are very expensive, it is desirable to utilize them as intensively as possible. Simulation modelling techniques are being applied to a wide range of container terminal planning processes and operational analysis of container handling systems. These models have become extremely valuable as decision support tools during the planning and modelling of container terminal operations. Simulation of the logistics activities related to the arrival, loading/unloading and departure processes of ship-berth link can be carried out for different usages such as design of container yard, increase productivity and efficiency of terminal equipment on quay cranes, yard trucks and yard cranes. Analysis and planning of container terminal transfer operations from the quay to the container yard etc. These logistics activities are particularly complex and very costly since they require the combined use of expensive infrastructure capacities especially berths and container yard. Container terminal operations are required to serve containers as quickly as possible. There are operational characteristics of the container yards that play important role in evaluation of the container yards utilization. These are the wide of container yard, the storage time, and the capacity of the container yard.

The Port of Singapore Authority

The Port of Singapore Authority runs one of the most technologically advanced ports and information technology is the tool behind making it the most efficient port in the World (lee Partridge, Teo and lim).The Country is in severe lack of land hence, the efficient utilization of existing land is crucial for the port and this was achieved by the sophisticated technology used in the port. This is a good example of overcoming physical limitations by the proper utilization of information technologies. The information system in port of Singapore is separated into three levels (applagate, dustin, and macfarlan, 2003). The Singapore experience shows how IT can reduce the consequences of disadvantages; Singapore cannot dramatically increase its land area, but it can and has used IT to increase the capacity of its constrained physical resources to run a large Port. Singapore’s strategy of supplementing its location and harbor with manmade resources has overcome the limitations of the natural resources to create a Port whose location, harbor, infrastructure, and operations and information technology combined are rare, valuable, inimitable and no substitutable. While Operations and Information Technology has helped reduce labuor in some instances, reduce time and increase quality, its major contribution has been to create flexibility. This flexibility allows Port of Singapore Authority to enlarge the capacity of the Port to handle more ships and cargo. In this way, operations and information technology take on a role comparable to physical infrastructure; one can expand a Port physically to provide more capacity, or one can employ technology to increase the volume of cargo handled by an existing physical infrastructure. The combination of space restraints and Operations and Information Technology innovations increased productivity as well. Because the Port’s land area is small, yard cranes and prime movers have shorter distances to travel than in physically larger Ports, while Operations and Information Technology applications help make efficient use of stacked containers. The case points out an important characteristic of operations and information technology; it can be used to expand capacity without adding investment in plant and equipment or physical space. Technology helps the firm utilize assets more effectively. This same principle applies in other settings as well; a railroad can reduce the need for new locomotives through systems that monitor their mechanical condition, and systems that provide more efficient scheduling of trains. A manufacturing company can increase the capacity of its plants through better production control and scheduling systems. (John et al.)

Port of Dar es salaam and Mombasa port

The port of Dar es salaam which during the East Africa Community was being run together with Mombasa as one under East Africa Harbours and Railways before the breakdown in 1978 have been competing for cargo destined to the land locked countries in East and Central Africa have been experiencing nearly similar logistical factors that have been affecting their port performances. There is some similarity in the geography of the Ports of Dar es Salaam and Mombasa; both are located on sea inlets or creeks, with long, naturally–protected shorelines on the two sides of the creek. The main facilities of both ports are located on the city side of the creek, which limits their expansion possibilities. Moreover, there is no practical way of expanding these terminals’ areas since in both ports the marine port facilities are cordoned by the city or other private facilities. The small backup area provides for relatively small container yards. The resulting shortage in container yards currently is the main source of terminal congestion and poor port performance in both ports. A related and even more severe problem is traffic congestion inside and outside these terminals. The container yards in both ports seem to have difficulties in serving ship and gate traffic at the same time. The result is that the STS cranes often wait for yard tractors, a ma-jor factor for the low crane productivity and subsequently low berth productivity. Dar es Salaam Port Authority in trying to address these challenges of yard capacity introduced the Inland Container Depots Integration Program which was intended to increase berth productivity by relieving the traffic congestion while increasing the available container yard space. The level of efficiency of port operations and the volume of traffic Mombasa and Dar es Salam are able to handle directly affect the performances of road, rail, and inland navigation systems along the Northern and Central corridors. For example, increases in the volume of containers handled by the two ports also increase the number of trucks and railcars that operate along the corridors. In absence of adequate measures that increase the capacity of roads, railways, warehouses, dry ports, and Customs to handle the new traffic volumes, congestion and inefficiency follow as unintended effects of business success of the two ports. (Anna et al., 2014) The major factors affecting port dwell and performance time as revealed by the survey conducted by International Peace Information Service and TransArms-Research include the following: System reliability for ports and customs authorities which is affecting the passing of customs entries and issuance of release orders, rigidity of the clearance process means that any errors in declarations and manifests are heavily punished as shippers who complete a form for rectifying such errors have to content with an average 7 days to have their entries passed, at which point their cargo has already started to incur storage and demurrage charges, Complexity in fulfilling documentation for transit related cargo and Too many government agencies involved in the goods clearance process The port of Mombasa management by the very nature of its business attracts a lot of interest nationally, locally and regionally. The business also involves diverse players including government agencies and private players. The potential of this diversity has not been tapped for a coordinated and common approach to issues affecting the industry. Information dissemination, limited collaboration and partnerships continue to be a hindrance for stakeholder participation and involvement. Moreover negative publicity continues to taint the image of the Port. Mechanisms for collaboration and cooperation with stakeholders will be established to bring about synergy that will accelerate the achievements of Kenya Ports Authority goals (Bandari Magazine, 2010).

Target Population and Sample Size

A population refers to an entire group of persons or elements that have at least one thing in common (Kombo and Tromp 2006). The target population under study will be 600 Port Stakeholders with a certain level of knowledge of the Port of Mombasa and comparative ports in the Maritime Industry such as Singapore Port, Port of Dar es Salaam etc. The research sample put into consideration that there are few experts in Maritime industry especially in Kenya and hence the consideration of a conservative sample figure of 60 officials in maritime Sector, that will be 10% of the target population, the research will put into consideration old and new projects in the port of Mombasa as shown in table below;

DATA PRESENTATION, ANALYSIS AND INTERPRETATION

Data Analysis and Interpretation

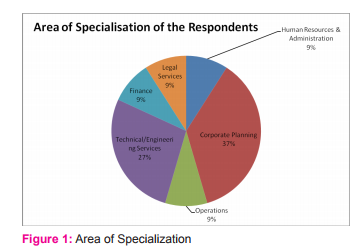

The Analysis was derived from the conceptual framework dependant vs Independents on the following features Infrastructure in relation to Port Performance, Cargo Handling Equipment in relation to Port Performance and Yard Capacity in relation to Port Performance The respondent’s distribution by gender shows that 64% of the officers were female and 36% of the officers were male. It show that more women were more responsive to this research than Male counterpart and the reason attributed to this was most of the Planning Officer sampled were Female. a large group of the officers were aged 41 above and this shows a wealth of experience in the transport industry, this is main attributed to the fact that most of the policy makers are in the senior and middle management level. The research targeted the planners and engineers in this study considering that strategies and port Infrastructure requires a lot of technical input, the responses shows that 37% and 27% responses rates from Corporate Planning and Technical/Engineering Services respectively. Responses were as showed below:

Infrastructure in relation to Port Performance

The findings shows that the most common feature contributing to poor port performances in the port of Mombasa are poor road network contributing 80%, non performing railway with 64%, then restriction of navigational channel with 57% and least is the inadequate ICT infrastructure with 44%, details below:

A technical view on KPA and strategies to improve port performance shows positive responses affirming the fact that KPA have a strategic plan for infrastructural

Cargo Handling Equipment in relation to Port Performance

KPA has a multiple of equipment for Cargo Handling, with the listed option for rating, inadequate terminal tractors were rated as the highest contributing factor to poor performance with 83% even though most of the respondents attributed this to regular breakdown of terminal tractors or poor planned maintenance regime where mostly more than 30% are on continuous breakdown. The engineers however attribute this with poor supervision from the operations side where a driver is allocated a truck but returns it to workshop on flimsy excuses that the breaks either are not good, lighting and since nobody will question the engineers to confirm the driver will just walk away after dumping the truck in the workshop. This was followed by Inadequate SSG equipment with 57% since most of the respondents were KPA staff the majority or nearly all outside respondents especially shipping agents/lines representative do not agree with this as they consider the 7 SSG currently in the terminal if each ship is allocated two and perform to the minimum industry practise of 20 moves per hour per gantry the performance can greatly improve. The research found out that the training of staff handling equipment is adequate meaning that Bandari College is playing a major role accordingly in contributing to better performance in the port of Mombasa A rating based on the listed strategic activities as put in place by KPA with the aim of Improvement on Performance at the Port of Mombasa shows the rating as listed: Modernization of Civil Works (80%), Modernization of Operations Equipment (57%), Introduction of ICT in Port Management (67%), Capacity Building for KPA staff (41.7%), Dredging and Deepening of Navigational Channel (32.2%), Upgrading of Power lighting system in the port Area (71.3%) and Upgrading of Dockyard –Dry Dock facilities (17.4%). The main bottleneck appears to be inadequate yard capacity with 80.0% of the respondents affirming to it, Inadequate skills on yard management, and poor planning for yard area was also identified as greatly contributing factor with over 80%, followed by poor utilization of yard area with 72% and The summary shows that yard capacity and inadequate skills on yard management plays a major role and its planning, utilization and management is a key feature in port operation and management of port facility. A correlation between dwell time and port performance is directly proportionate as it is about the provision of space for incoming cargo and yard utilisation. The less the dwell time the more the space is avail for more containers. The finding from research shows that there is a direct relation to poor performance in the port of Mombasa and the long dwell of cargo in the port area with 64% strongly agree with it as compare with a small number of 9% which did not agree with it.

Challenges facing Mombasa container terminal

Based on the finding from the research, the main challenges faced by the current management which are contributing to poor performance appear to be Lack of funds for Infrastructure/capital works with 80.0%, Lack of Support from Central Government with 57.4%, Lack of adequate training for engineers with 57%, Unclear Strategies by Central Government with 44%. There are others which though are there a contributing factors but were given less weight by the research finding are Lack of commitment from Top KPA Management with 25% and Ineffective Management in the Port and others Support Service Challenges with 17%.

Recommended Area of improvement

The following are recommendation raised as the most likely to lead to improvement in port performance if put in place; terminal yard capacity expansion (80%), improvement in terminal equipment (57%), legal reforms (54.0%), rehabilitation of terminal facilities (43%), terminal quay length extension (32%), improvement in ICT infrastructure (25%) and institutional reforms (17%)

Main causes of Poor Performance at Mombasa port

The research summaries the causes of poor performance in the port of Mombasa according to the findings are: lengthy customs clearing procedures, rapid growth of container trade, frequent break down of Kenya Revenue Authority and Kenya Ports Authority, IT Systems, slow gate out process and slow container off-take to Container Freight Station, inadequate yard capacity and lengthy KRA clearing procedures, poor yard planning and in adequate usage of IT in yard planning, poor working corporate culture by the corporate staff and poor hinterland connectivity.

CONCLUSIONS

Some of the conclusion observed from this research show that port activities at the Port of Mombasa are more or less control by international linkage of business happening internationally, global business trend, competition in the Maritime industry and regional development contributes towards more activities on imports and exports. The research finding shows that factors which are leading to poor performance in the port of Mombasa are attributed to lack of funds for Infrastructure/capital works, lack of support from Central Government, lack of adequate training for engineers, unclear strategies by Central Government, lack of commitment from top KPA management, ineffective management in the port and others support service Challenges. The research reveal that multi sectorial linkage such as working relation between KPA, KRA, Shipping lines/agencies, KEBS, Police etc play a role is contributing to poor performance in the port of Mombasa as most of the stated institutions have different reporting structures.

References:

1. Anna B, Peter D, Sergio F, Ken M(2014) Supply Chains and Transport Corridors in East Africa IPIS/Trans Arms

2. Applegate, L.M., Dustin, R.D., and McFarlan, F. W. (2003). Corporate Information Strategy and Management: Text and Cases New York: McGraw-Hill/Irwin.

3. Banfield P. and Kay. R. (2008): Introduction to human resource management. London: Oxford University Press.

4. Bandari Magazine (2010): Kenya Ports Authority Internal Magazine.

5. Bandari Magazine (2012): Kenya Ports Authority Internal Magazine.

6. Drewry Consultants (2007), “Annual Container Market Review and Forecast”.

7. Drewry (2006), Annual Review of Global Container Terminal Operators.

8. John R.M. Gordona, Pui-Mun Leeb, Henry C. Lucas Jr.(2005) A resource-based view of competitive Advantage at the Port of Singapore; The Journal of Strategic Information Systems

9. Kamau. M (2014); The Transporter; A publication of the Kenya Transporters Association Limited

10. Kenya Shipping Council (2008) Policy Position on Transport and Logistics Chain in Kenya. KAM, Nairobi-Kenya

11. KPA Container Freight Station Policy (2014); http://www. kpa.co.ke/InfoCenter/News/Pages

12. Kenya Ports Authority, STRATEGIC PLAN; 2013 – 2018

13. Kenya Ports Authority, Business Plan 2010/11- 2012/13

14. Kenya Ports Authority (2009), Master Plan Study of the Port of Mombasa

15. Kombo, D. K., and Tromp, D.L. (2006). Proposal and thesis writing: An introduction. Nairobi: Pauline’s Publications Africa

16. Langat G (2013) Cost, Time and Complexity of the East African Logistics Chai, Nairobi Kenya. Kenya Shippers Council Publication

17. Mangan, J and Cunningham, J (2001) Irish Ports: Commercialization and Strategic Change. Business strategy review

18. Pálsson. G, Alan H, and Raballand G (2007). “Port and Maritime Transport Challenges in West and Central Africa.” Sub-Saharan Africa Transport Policy Program Working Paper 84, World Bank, Washington, DC.

19. Raballand G, Refas S, Beuran M, and Isik. G.(2012) Poverty Reduction and Economic Management (prem) network(2012) world bank; Washington DC

20. Salaman, Graeme; Storey, John; Billsberry, Jon. 2nd Edition (2005); Strategic Human Resource Management: Theory and Practice. Sage Publications Ltd.

|

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License