IJCRR - 13(14), July, 2021

Pages: 69-74

Date of Publication: 20-Jul-2021

Print Article

Download XML Download PDF

To Evaluate Marginal Fit of Single Implant-Supported Metal-Ceramic Crowns Fabricated by Direct Metal Laser Sintering and Lost Wax Technique: An In Vitro Study

Author: Harshita Narang, Urvashi Sukhija

Category: Healthcare

Abstract:Introduction: Porcelain fused to the metal prosthesis is one of the widely used dental prosthesis. The aim of this in vitro study is to check the marginal fit of a single implant-supported metal-ceramic crown fabricated by the direct metal laser sintering method compared with crowns fabricated using the lost wax technique. Materials and Method: The study conducted compares the marginal fit of single implant-supported porcelain fused to metal crown fabricated using the most ancient and conventional lost wax technique and the most recent yet emerging Direct Metal Laser Sintering (DMLS) technique. This study also compares both techniques based on the marginal fit of crowns. A total of 20 porcelain fused to metal crowns were prepared for this study. 20 implant abutments fixed into implant analogues, embedded into acrylic resin blocks were divided equally (n=10) into two groups Group A (lost-wax technique) and Group B (DMLS technique). On the abutments, crowns for the mandibular first molar were prepared by these two techniques. Four points were marked on each aspect (lingual, buccal, mesial and distal) of the crown at the level of the abutment, which was analyzed under a stereomicroscope at 65x. Three readings at each point were noted and the observations were statistically analyzed. Results: The lowest mean marginal discrepancy values (39.9 \? 1.8 µm), (40.3 \? 1.5µm), (39.2 \? 1.2µm) and (37.3 \? 1.7µm) were observed for Group B (DMLS) at all four points marked, respectively which were significantly better as compared to that of Group A (Lost-Wax) that showed (58.4 \? 1.2µm), (55.5 \? 0.98µm), (56.9 \? 0.91µm) and (55.7 \? 0.92 µm) values at the four marked points. Conclusion: The results revealed that the crowns fabricated by the DMLS technique provided better marginal fit as compared to the crowns fabricated by the Lost-Wax technique.

Keywords: Implant-Supported crowns, Lost-wax technique, Metal-Ceramic crowns, Marginal fitting

Full Text:

INTRODUCTION

To restore the lost functions, esthetics and phonetics, the use of dental implants has become a contemporary regime with unceasing development in the science of implantology and osseointegration.1 The increased demand in clinical applications has made many researchers conduct many scientific investigations leading to an evolution in implant systems, techniques of framework fabrication and treatment modalities. 1,2,3

Porcelain fused to the metal prosthesis is one of the widely used dental prosthesis. For the long?term success of the prosthesis, a good marginal fit is a prerequisite. The appropriate seating of prosthesis to implant abutments is very essential to ensure the longevity of the treatment.4

Various factors that affect the marginal fit of the implant-supported fixed prosthesis include; bone quality, adjacent teeth present, the diameter of the implant, implant-bone contact, abutment fixation into the implant, final impression material and technique, master cast produced, the accuracy of impression-transfer onto the cast, wax used for fabrication of pattern, investment used for casting, the alloy used for coping, properties of the alloy, the bulk of coping, type and brand of ceramic used, shrinkage and various properties of ceramic.

Technology in dentistry is speed rocketing similar to other various fields. One of these technologies is ‘Direct Metal Laser Sintering. This technique is based on an additive aspect of CAD/CAM technology. The reason why it is called 3D printing is that it built successive layers of 0.02-0.06 mm. Onto the powdered metal, a high beam laser is focused which helps to infuse the metal and forms the layer. This process of fusing the metal layer-by-layer is carried till the final dimensions are acquired. It doesn’t require any milling machine as required in subtractive milling technology.

For crown fabrication, an ancient yet conventional technique is used for decades that is ‘Casting technique or Lost-Wax technique’. It involves the preparation of a mould with the help of a wax pattern which is put in a burnout furnace and it leaves behind a cavity into which the molten metal can be poured for casting.5,6,7

The main objective of this study is to compare the passive fit of the metal-ceramic crowns fabricated by the above mentioned two techniques, one of which is the oldest and conventional technique whereas, the other one is the latest digital technologies.

MATERIAL AND METHODOLOGY

The study compares the marginal fit of the single implant-supported metal-ceramic crowns fabricated by different techniques, that is the lost wax and the direct metal laser sintering technique.

Preparation of the samples:

After applying a coat of Vaseline on the inner walls of cylindrical metallic die into which modelling wax was melted. The solidified wax blocks were used as a mould. With the help of Vernier calliper (fixed at 1 inch/2.5cm), 2 perpendicular lines were drawn to mark the centre, where implant analogues were fitted. Impression transfer was attached to the analogue and with the help of a surveyor, the parallelism of the implant analogue was checked.

A total of 20 samples were made similarly. All the moulds were acrylized in cold-cure acrylic resin. Tissue-level implant abutment with the shoulder was then placed over each analogue (Fig. 1).

Grouping of samples:

The prepared 20 samples were divided into two groups (n=10):

After grouping samples were numbered from 1 to 10 into groups (Group A: GA1-GA10 and Group B: GB1-GB10) respectively.

The acrylic block samples were collected and points were marked over the shoulder of the abutment on 4 aspects that is, distal (D), mesial (M), lingual (L) and buccal (B) using diamond needle bur (Fig. 1).

Preparation of wax pattern:

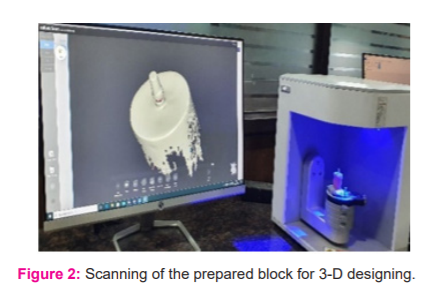

The prepared samples were scanned with an extraoral scanner (Medit) (Fig. 2) Wax patterns for mandibular first molar were prepared for Group A using Computer Assisted Designing system (Exocad) to maintain a uniform thickness. The uniform cement gap was maintained at 0.02 mm from the top and 0.05 mm from the margins of the wax patterns. After the design was finalised, the STL (standard tessellation language) file was transferred to the Computer Assisted Milling system (Arum; Doowon) for milling.

Preparation of Metal Copings:

Group A (Lost-Wax):

The casting was done with Ni-Cr alloy, the copings were checked for surface roughness. Air-borne abrasion material, (Al2O3 abrasive particles in sandblasting machine) and finishing & polishing were done.

Group B (DMLS):

The CAD design prepared for Group A copings were used for copings of Group B. DMLS machine (HBD-100D) was used which included pre-sintered Co-Cr metal powder and laser beam. After the procedure was completed, the metal copings were retrieved and surface treated for a smooth surface with Al2O3 abrasive particles in sandblasting machine. The finished metal copings were then ready for ceramic application (Fig 3, 4).

Ceramic application:

Ceramic was applied over all the samples, imitating mandibular first molar crowns.

Two-paste auto-mix system Resin-Modified Glass Ionomer Cement (RM-GIC) was was used to cement the crowns over abutments under constant finger pressure. Once the fit was ensured to be satisfactory, the samples were checked using a stereomicroscope at 65X at the marked 4 points. At each point, three readings were taken with the digital analyser. The readings at each point, were numbered (example: for point L- L1, L2, L3 and so on) and were tabulated accordingly.

All the data were recorded and tabulated and statistical analysis was carried out using a t-test.

RESULTS

The readings obtained for each sample at each aspect were obtained and interpreted using a t-test. Based on readings and results obtained via t-test, the comparison was made for both the groups for individual aspects.

For all the three readings obtained for all the samples at four aspects, the mean was calculated aspect-wise for each sample and the mean reading was put for the comparative analysis.

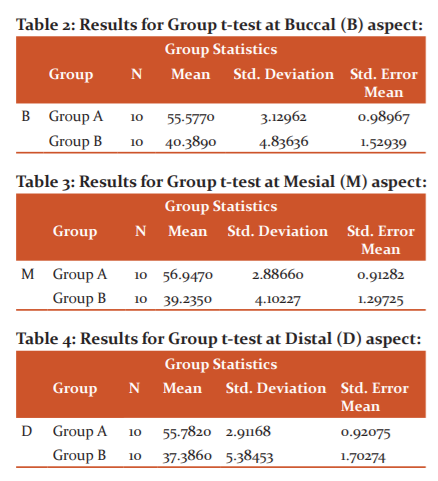

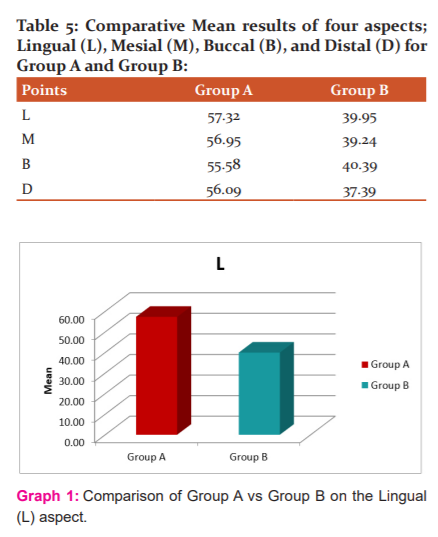

At the Lingual (L) aspect, the t-test results (Table 1) show higher mean values for samples prepared under Group A (lost-wax technique) as compared to samples prepared under group B (DMLS technique). This implies less discrepancy at margins for the Group B samples, inferring Group B (DMLS technique) to be better than Group A (Graph 1).

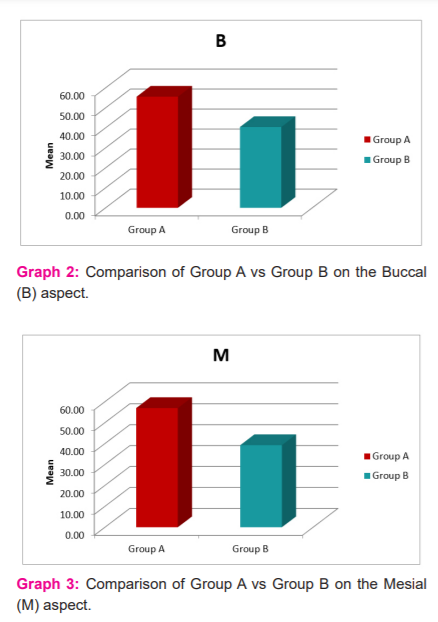

At Buccal (B) aspect, the t-test results (Table 2) show higher mean values for samples prepared under Group A (lost-wax technique) as compared to samples prepared under group B (DMLS technique). This implies less discrepancy at margins for the Group B samples, inferring Group B (DMLS technique) to be better than Group A (Graph 2).

At the Mesial (M) aspect, the t-test results (Table 3) show higher mean values for samples prepared under Group A (lost-wax technique) as compared to samples prepared under group B (DMLS technique). This implies less discrepancy at margins for the Group B samples, inferring Group B (DMLS technique) to be better than Group A (Graph 3).

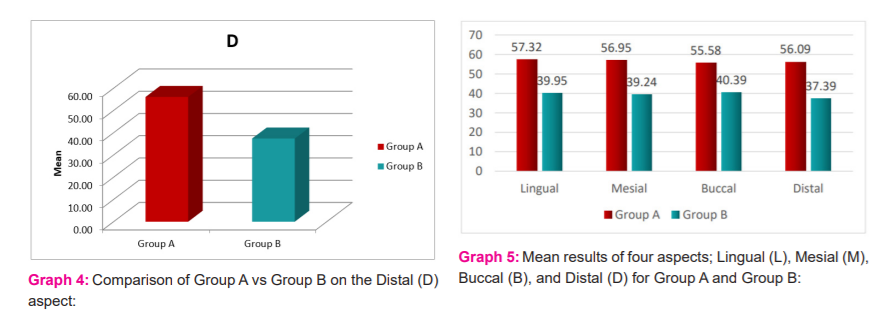

At Distal (D) aspect, the t-test results (Table 4) show higher mean values for samples prepared under Group A (lost-wax technique) as compared to samples prepared under group B (DMLS technique). This implies less discrepancy at margins for the Group B samples, inferring Group B (DMLS technique) to be better than Group A (Graph 4).

The mean values obtained for individual points are tabulated (Table 5). They show a comparison between each point as well as both the groups (Graph 5). The mean readings for group A are higher than the mean readings of Group B.

The mean readings of the individual four aspects are depicted. This graph clearly shows the higher mean values for Group A (lost wax) as compared to Group B (DMLS).

DISCUSSION

The first permanent tooth to erupt in the oral cavity are mandibular first molars and are most often the first to be lost by the carious decay.5,7 It can be considered that an important role is being played by the first molars which no other tooth in the dental arches play.8

The distinctiveness of the implant dentistry is restoring the functions, esthetics, comfort of the patient at the edentulous site regardless of atrophy, or any disturbance in the stomatognathic system.9

For clinical acceptability of the fixed prosthesis (crowns), the marginal fit is one of the most important criteria. Dr. William H. Taggart in 1907 introduced the lost-wax casting technique for casting alloys.

Since 19th century, CAD/CAM had put its feet into the dental industry. Dr. Duret was the first person to develop a dental CAD/CAM device. CAD-CAM has different forms of processing: subtractive (milling) and additive (DMLS).

The present in-vitro study evaluates and compares the marginal fit of single implant-supported metal-ceramic crowns fabricated using conventional lost wax and DMLS techniques. A total of 20 single-implant supported mandibular first molar (#46) Porcelain fused to Metal (PFM) crowns samples were prepared.10

After conducting the study, results showed significantly lower values for the Group B samples (39.23 µm) that were fabricated with Direct Metal Laser Sintering (DMLS technique) as compared to Group A samples (56.48 µm) fabricated with Lost-Wax technique, implying DMLS technique to produce better marginal fit of the prosthesis as compared to Lost-wax technique.

The results of our study disagree with that conducted by Park J.K et al., Ullattuthodi S et al., Nesse H et al., and Katsoulis et al.11-14 All these researchers concluded in their studies that the conventional casting or lost-wax technique for fabrication of copings is better than CAD-CAM or DMLS technique.

League R.C et al., Ortorp A et al., Suleiman S.H et al., Kilicarslan M.A et al., Harish V et al., Sundar et al. performed a study comparing laser sintering technique and lost-wax technique for fabricating metal copings.15-20 They all concluded in their study that DMLS provided less marginal gap and better internal fit for the copings. Similarly, Lovgren et al., Sharma M et al., Keles M et al., Gaikwad B.S et al., and Arora A et al., performed similar comparative studies.21-25 Likewise, they all concluded in their studies that DMLS fabricated better-fitted prosthesis as compared to lost wax or other fabrication techniques that were kept in comparison groups. So, these studies showed results that were in favour of the present study.

Conclusion

The results revealed that the crowns fabricated by the DMLS technique provided better marginal fit as compared to the crowns fabricated by the Lost-Wax technique.

Conflict of interest: nil

Source of funding: self

Authors contribution

-

DR. Harshita NARANG- data collection

-

DR. Urvashi SUKHIJA- manuscript writing

References:

-

Brantigan JW, Brantigan John W. Prosthetic implant. United States patent US 4,834,757. 1989;30:1-7.

-

Brunski JB. Biomechanical factors affecting the bone-dental implant interface. Clin Mater. 1992;1;10(3):153-201.

-

Sahin S, Çehreli MC. The significance of passive framework fit in implant prosthodontics: current status. Implant Dent. 2001;1;10(2):85-92.

-

Zaghloul HH, Younis FJ. Marginal Fit of Implant-Supported All-Ceramic Zirconia Frameworks. J Oral Imp. 2013;39(4):417-2

-

Holden JE, Goldstein GR, Hittelman EL, Clark EA. Comparison of the marginal fit of pressable ceramic to metal-ceramic restorations. J Prosthodont. 2009;18(8):645-8.

-

Anusavice KJ, Shen C, Rawls HR, editors. Phillips' science of dental materials. Elsevier Health Sciences. 2012;11th ed. 564-620.

-

Shi X, Chang L, Zou G. Marginal adaptation of metal crowns: comparison of two production methods. Chinese J Tissue Eng Res. 2014;1(25):4014-19.

-

Moore WD. The First Permanent Molar. J Am Dent Assoc. 1927;1;14(7):1213-221.

-

Resnik R. Misch's Contemporary Implant Dentistry E-Book. Elsevier Health Sciences; 2020;4th ed.1-30.

-

Chen CJ, Papaspyridakos P, Guze K, Singh M, Weber HP, Gallucci GO. Effect of Misfit of Cement-Retained Implant Single Crowns on Crestal Bone Changes. Int J Prosthodont. 2013;1;26(2):135-137.

-

Park JK, Lee WS, Kim HY, Kim WC, Kim JH. Accuracy evaluation of metal copings fabricated by computer-aided milling and direct metal laser sintering systems. J Adv Prosthodont. 2015;1;7(2):122-128.

-

Ullattuthodi S, Cherian KP, Anandkumar R, Nambiar MS. Marginal and internal fit of cobalt-chromium copings fabricated using the conventional and the direct metal laser sintering techniques: A comparative in vitro study. J Indian Prosthodont Soc. 2017;17(4):373-380.

-

Nesse H, Ulstein DM, Vaage MM, Oilo M. Internal and marginal fit of cobalt-chromium fixed dental prostheses fabricated with 3 different techniques. J Prosthet Dent. 2015;1;114(5):686-92.

-

Katsoulis J, MericskeStern R, Enkling N, Katsoulis K, Blatz MB. In vitro precision of fit of computer?aided designed and computer?aided manufactured titanium screw-retained fixed dental prostheses before and after ceramic veneering. Clin Oral Impl Res. 2015;26(1):44-49.

-

Oyague R.C, Lynch CD, Turrion AS, Lopez-Lozano JF, Torres-Lagares D, et al. Misfit and microleakage of implant-supported crown copings obtained by laser sintering and casting techniques, luted with glass-ionomer, resin cement and acrylic/urethane-based agents. J Dent. 2013;1;41(1):90-6.

-

Ortorp A, Jonsson D, Mouhsen A, Von Steyern PV. The fit of cobalt-chromium three-unit fixed dental prostheses fabricated with four different techniques: A comparative in vitro study. Dent Mater. 2011;1;27(4):356-363.

-

Suleiman SH, Vult von Steyern P. Fracture strength of porcelain fused to metal crowns made of cast, milled or laser-sintered cobalt-chromium. Acta Odontol Scand. 2013;1;71(5):1280-1289.

-

Kilicarslan MA, Ozkan P, Uludag B, Mumcu E. Comparison of internal fit between implant abutments and cast metal crowns vs. laser-sintered crowns. J Contemp Dent Pract. 2014;1;15:428-32.

-

Harish V, Mohamed Ali SA, Jagadesan N, Mohamed Ifthikar SS, Debasish Basak FH. Evaluation of internal and marginal fit of two metal-ceramic systems–In vitro study. J Clin Diag 2014;8(12):1-12.

-

Sundar MK, Chikmagalur SB, Pasha F. Marginal fit and microleakage of the cast and metal laser sintered copings—An in vitro study. J Prosthodont Res. 2014;58(4):252-258.

-

Lovgren N, Roxner R, Klemendz S, Larsson C. Effect of production method on surface roughness, marginal and internal fit, and retention of cobalt-chromium single crowns. J Prosthet Dent. 2017;1;118(1):95-101.

-

Sharma M, Bansal A, Panthi S, Malik SS, Sharma A. To Evaluate the Marginal Fit of Metal Copings Fabricated by Conventional Casting Procedure and Direct Metal Laser Sintering Technology–An In Vitro Study. Dent J Adv Stud. 2017;5(01):39-46.

-

Keles MA, Turker SB. In Vitro Gap Changes After Porcelain Firing Cycles of Three and Four Unit of CAD/CAM Milling, Laser Sintering and Cast Metal-ceramic Restorations. Clin Exp Health Sci. 2019;9(3):271-277.

-

Gaikwad BS, Nazirkar G, Dable R, Singh S. Comparative evaluation of marginal fit and axial wall adaptability of copings fabricated by metal laser sintering and lost-wax technique: An in vitro study. J Indian Prosthodont Soc. 2018;18(1):47-52.

-

Arora A, Yadav A, Upadhyaya V, Jain P, Verma M. Comparison of marginal and internal adaptation of copings fabricated from three different fabrication techniques: An in vitro study. J Indian Prosthodont Soc. 2018;18(2):102-107.

|

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License