IJCRR - 8(6), March, 2016

Pages: 30-34

Date of Publication: 22-Mar-2016

Print Article

Download XML Download PDF

DEVELOPMENT OF DOUBLE LAYER KNITTED FABRIC FOR SPORTSWEAR USING TENCEL/POLYPROPYLENEFIBRES

Author: P. Sakthi, K. Sangeetha, M. Bhuvaneshwari

Category: Healthcare

Abstract:In day to day life the requirement for the athletics and leisure wear are increasing to better their performance. The performance requirements of many sports goods often demand widely on different properties. Also the textile must fulfill the requirements such as fit, comfort, drape and easy movements of the consumers. The active sportswear fabrics has been developed in recent years and progressing towards high functions and to achieve comfort. The focus is to diversify the sportswear textiles in fibrous material and technology in manufacturing. The factors contributing for developing active sportswear fabrics are: polymer/fiber science, production and finishing techniques to obtain a sophisticated fiber, modified structure of yarns and fabrics. In this study, the sportswear are developed from polypropylene and tencel fibers by using a knitting technique, Ponte de roma structure (double layer knitted fabric by interlock structure) and analyzed for their various properties such as structural, mechanical and comfort properties of the knitted fabric samples.

Keywords: Fiber, Yarn, Fabric, Sportswear, Textile, Knit, Polypropylene and tencel

Full Text:

INTRODUCTION

The people are paying more attention to sports activity and that the market for sportswear continues to expand. Developing sportswear solutions in this field are invaluable in order to produce an adequate response to these increasingly demanding expectations. Recently developed functional fibers, innovations in new structures and garments contribute substantially to the wearing comfort of these types of clothes. Nowadays, from very simple manmade fibers to much more complex fabric structures are effectively used in sportswear garments1 .

Sportswear requires some important functional and comfort properties such as optimum heat and moisture regulation, rapid moisture absorption and conveyance capacity, good air and water permeability, prevention of a long term feeling of dampness, low water absorption of the layer of clothing facing the skin, quick drying fabric to prevent catching cold, pleasant to skin, soft, non-abrasive and non-chafing, dimensionally stable even when wet, durable, lightweight, soft and pleasant touch, easy care, smart and functional design. All required properties are not possible to achieve for sportswear in a simple structure of any single fiber. The behavior of the fabric is mainly depending on its base fibers properties, fabric construction, weight or thickness of the material and presence of chemical treatments5 . The performance of layered fabrics in thermo-physiological regulation is better than single layer textile structure.

The most common strategy used to give high performance in synthetic fiber based active sportswear is to use a two layer fabric with a hydrophobic skin contact layer and a hydrophilic outer layer. In doing so, it takes away some of the body heat and keeps the body cool. On the inside, a synthetic material with good moisture transfer properties and good capillary action e.g. Polyester, Nylon, Acrylic or Polypropylene is used, whereas on the outside, a material with a good absorber of moisture, e.g. Cotton, Tencel, Wool, Viscose Rayon or their blends can be placed2 . In this study, the sportswear fabrics are developed from polypropylene; being used in sportswear have very low moisture absorbency, excellent moisture vapor permeability,

wicking capabilities and has the advantage of providing insulation when wet, and tencel fibers, deliver the hydrophilicity needed for transport of moisture through the fabric and for spreading across the outer surface3 .The double layer knitted fabric is developed with above said fibers by interlock structure using a knitting technique called Ponte de roma structure, a dense structure with stretching property is higher in lengthwise than in breadth wise, has advanced dimensional stability4 .Then the fabric is analyzed for their various properties such as structural, mechanical and comfort properties of the knitted fabric samples.

MATERIALS AND METHODS

Selection and Purchase of yarns a. Tencel: 100% Tencel yarn was selected for this study. The combed tencel yarn count with 40’s was purchased at the cost of Rs.325/- per kg from Cheran Spinners Pvt Ltd., Erode. b. Polypropylene: 100%polypropylene yarn of 120 Denier was selected and purchased at the cost of Rs.380/- per kg from Filatex India. Ltd, Dadra and Nagar Haveli. The yarn package is shown in figure 1.

Selection of fabric construction The technique of fabric construction selected for the study is knitting, as it is the most common fabric structure for base layer and possesses high stretch and recovery by providing greater freedom of movement, shape retention and tailored fit. Knitted fabrics also have relatively uneven surfaces (less direct contact with skin), which make the wearer feel more comfortable than smooth surfaced woven fabric of similar fiber compositions. a. Double layer knitted fabric The bi-layer weft knitted fabric with wicking fibers: polypropylene in their inner layer and tencel as outer layer, on circular double jersey knitting machine with interlock structure is prepared, which can able to transfer moisture from skin to the environment. Thus the bi-layer knitted fabric is prepared for the sportswear fabric as shown in the figure.

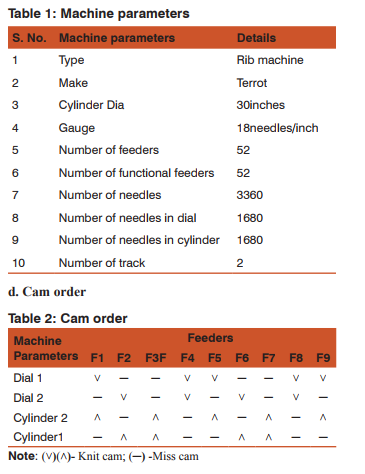

This fabric provides a comfortable environment for the wearer and consequently able to handle moisture vapor and sweat produced by the body during strenuous activity in sports to feel good. b. Selection of interlock structure- Ponte de roma Interlock fabric is double knit fabric is produced by the action of two needle by the interlinking of loops. The needles used were cylinder needle and dial needle. The interlock fabric is manufactured in various diameter and gauges. It depends upon end use of the fabric.

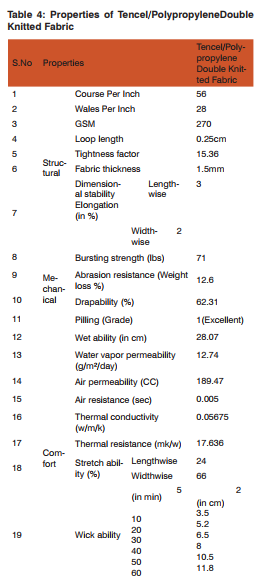

The fabric is a double knit, which means it is a double layer of fabric knitted with a 2 sets of needles on 2 needle beds most probably on a machine. As far as knits go, Ponte is a good fabric to start experimenting with. It is nice and stable, does not have a huge amount of stretch and won’t curl too much either when cut. The Knitting construction of Ponte de Roma was shown in Figure 2. c. Knitting machine details The weft circular knitting machine (type: rib machine) was chosen to knit the fabric. The main parameters of the machine are given below

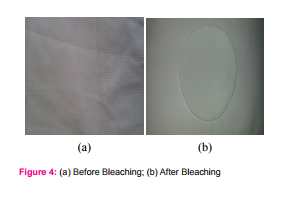

Processing of fabrics The above knitted fabric is bleached using Hydrogen Peroxide (H2 O2 ) in a pressurized High Temperature (HT) apparatus at the temperatures of 110 - 130°C for 1 hour withSodium Hydroxide (NaOH) as a Stabilizer, Imerol blue liquid and Acetic acid. After bleaching, the fabric is rinsed in water for 3times. Recipe: Hydrogen Peroxide (H2 O2 ) : 3% Sodium Hydroxide (NaOH) : 1% Imerol blue liquid : 1.5% Acetic acid : 2.5% Time :1 hour Temperature : 110 - 130°C Material to liquor ratio : 1:3 pH Value : 4.5

Fabric testing The knitted fabric is tested for various properties such as, a. Structural Properties; b. Mechanical properties and c. Comfort properties. a. Structural tests The knitted fabric is tested for structural properties such as Course per inch, Wales Density, GSM, Loop length, Tightness Factor, Fabric Thickness and Dimensional Stability using the standard methods. b. Mechanical properties The knitted fabric is tested for mechanical properties such as Bursting strength, Abrasion resistance, Drapability and Pilling using the standard test methods and the results are obtained. c. Comfort properties The knitted fabric is tested for various comfort properties such as Wet ability – drop test, Wick ability, Water remind ratio, Water vapor permeability, Air permeability, Air resistance, Thermal conductivity, Thermal resistance and Stretch ability using the standard test methods and the results are obtained.

RESULT AND DISCUSSION Structural properties The structural properties for the samples is analyzed and given in the table.

CONCLUSION

Fiber qualities and fabric structure always influences the fabric quality. In this study, attempts were made to understand the characteristics required in fabrics used for sports and active apparel productions and other allied applications.

Here we studied about the various possibilities and methods of producing double layered knitted fabrics with different material combinations. And also we have developed the double layer knitted fabric by interlock structure called ponte de roma structure with Polypropylene yarn (inner layer) and Tencel yarn (outer layer) and analyzed to evaluate the structural, mechanical and comfort properties of the fabric samples. The test results gives indication that double layered knitted fabrics made of different combinations influences the mechanical and comfort properties and hence suitable attentions have to be paid while choosing combinations for functional active and sportswear fabrics productions. The fabric sample have more GSM and thickness because the denier of the Polypropylene yarn is about 120 D. By the study we can conclude that the fabric tencel- polypropylene is most suitable for active sportswear.

ACKNOWLEDGEMENT

The authors would like to acknowledge the staff, who help for this project. They would also like to acknowledge the industrial people for their kind support. Authors acknowledge the immense help received from the scholars whose articles are cited and included in references of this manuscript. The authors are also grateful to authors / editors / publishers of all those articles, journals and books from where the literature for this article has been reviewed and discussed.

References:

1. Apurba Das, Ramasamy Alagirusamy and Pavan Kumar.(June 2011). Heat Transfer through Multilayer Clothing Assemblies: A Theoretical Prediction, Autex Research Journal, Vol.11 (2): Pp. 54-60.

2. Barnes J C and Holcombe B V. (1996). Textile Fiberusages for Sportswear, Textile Research Journal, Vol.79 (8):Pp.777-786.

3. Ziad Bayasi and Jack Zeng. (1993). Properties of Polypropylene Fiber Reinforced concrete.Materials Journal, Vol. 90 (6): Pp. 605-610.

4. Daiva Miku?ionience and Daiva Milašience. (2013).The influence of knitting structure on heating and cooling dynamic, Materials Science (Mediagotyra), Vol.19 (2): Pp.174-177.

5. David G Mehrtens and Kenneth C Mcalister (1962). Fiber Properties Responsible for Garment Comfort, Textile Research Journal,Vol.9:Pp. 628-665.

|

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License