IJCRR - 2(5), May, 2010

Pages: 20-29

Print Article

Download XML Download PDF

VENDOR DEVELOPMENT IN PHARMA INDUSTRY

Author: Manthan D Janodia, Kunal Saxena, D.Sreedhar, Virendra S Ligade, Ajay Pise, Udupa N.

Category: Healthcare

Abstract:Vendor development is essential for buying of material in right quantity, of right quality, at right price from a right source, at right time and place. Thus, source selection begins after the user department forwards material requisition form to purchase department. The purchase department thus, calls

quotations, invites tenders, receives and processes them. The comparative statements, on the basis of offers made must exhibit in addition to price differentials, a brief history of tenders in respect of their quality standards dependability and performance reliability. After critical examination of all the aspects based on information supplied by them, a particular vendor is selected who can establish suitability criterion in most

effective manner. On asking, selected vendor generally supply „initial sample?. If approved, this would then be followed by „initial supply?. The evaluation of initial supply results should be supplemented by on-the-spot study team visits at the vendor?s plant consisting of production engineers, quality controllers, cost-accountants and finance expert. The team should make a detailed study of processes, organization and other allied matters necessary for vendor evaluation. This composite scheme would then form the basis for vendor selection rather than by results of a single sample as practiced in many organizations. On the basis of

this study, bulk supply orders should follow.

Full Text:

Vendor Development:-

In a store and material organization, it is essential to have many sources of supplies so that supplies may be had as per requirements as well as at economic costs. From commercial point of view, it is always desirable to have more than one supplier for a particular item. Sometimes it helps to improve quality and import substitution. Thus, new sources have to be found from time to time for dropping out existing sources which prove inefficient. Vendor development is a continuous process and starts from collecting names and addresses from DGS and D, trade journals like eastern pharmacist, pharma times, newspaper advertisements, IDMA bulletin and also from trade directories like Directory of small scale industries, etc. The routine sales call by representative of supplier is another good source of information. Trade shows, technical exhibitions, pharmaceutical conferences and seminars give information regarding new materials and specifications.

Vendor Selection:-

Depending upon suppliers' reputation, quality, efficiency, industrial relations and technical excellence, materials should be selected. ompetence, efficiency and quality. After collecting the details, a list of prospective vendors may be drawn up for the evaluation. Following information may be needed:

Organizational Structure

- Whether it is a proprietary/partnership/private limited or public limited company

- Whether it is a government undertaking or a public sector corporation

- Number of managerial personnel employed at various levels

- Number of supervisory personnel employed at various levels Total strength of the workforce

Manufacturing Capability

A list of equipments installed at plant level Technical details and specifications of such equipments

Manufacturing capacity of particular items

- Already committed capacity

- Method of production planning

- Methods of follow up and progress-chasing

- Materials handling systems and equipments used

- Expansion plans and future programs

Technical Skill and testing facility

- Numbers of technical personnel

- Experience of technical personnel

Delivery and quality required at competitive prices are most important. Before selecting any new material, the plant should be inspected for technical c

- Design and development of facility

- Frequency of calibration of gauges and equipments

- Testing equipments used for purpose of quality control

- Methods of sampling and testing data regarding past rejection rates

Financial Capacity

- Initial capital investment and working capital requirements

- Financial sources and loan facilities from banks, financial institutions, etc

- Inventory turnover and profits, etc

- Clearances of government duties and rates

Location and infrastructural facilities

Whether unit enjoys facilities with regard to location, power and transit, etc.

Past performance and after sales service

Whether the unit has good record of past performance and after sales service compared to other suppliers

Vendor Rating In a large store and material organization, where a large number of parts and components are supplied by different vendors, it becomes difficult to keep a track on their performance. Therefore, in order to compare performance of various vendors, it is essential ti rate them individually. The rating may be done as per following parameters:

-Quality Performance

-Delivery Performance

. Number of lots accepted * 100 = Weightage

Number of lots supplied

Delivery Performance: It can be done in two ways.

a) Adherence to time schedules

b) Adherence to quantity schedule

- Adherence to time schedule = Number of delivery made in time * weightage

Total number of scheduled delivery

- Adherence to quality schedule = Quantity supplied * weightage

Scheduled delivery

- Price Performance: Price is another very important criteriaon for evaluating a vendor which can be worked out as

Minimum Price Offered * weightage

Vendor?s profile

Final evaluation, however will depend on judgment, which is substantiated by facts.

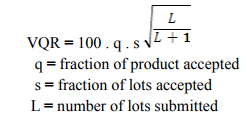

Vendor Quality Rating(VQR):- VQR is another aspect which characterizes the quality performances of vendors in a concise and meaningful form, VQR utilizes the information regarding the number of lots submitted and the percent of lots and total quality accepted. These are evaluated as an integral unit as below.

Resulting ratings may be numbered between 0 and 100 with high values representing good performance.

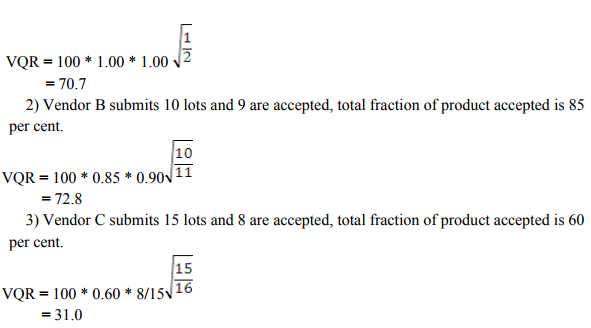

Eg. 1) Vendor A submits one perfect lot, where q = 1.00, s = 1.00, L = 1

These examples clearly indicate that B is the best vendor as we may have to expect based upon good performance over 10 lots. The performance of vendor A on single lot is not conclusive enough to give him a superior rating.

Supplier Quality Assurance Program

A supplier quality assurance program helps material management in obtaining assurance of quality of the items supplied by outside vendors, to the specifications needed at minimum cost. A good specification should be unambiguous and must be measured and expressed in a form which is capable of being translated into materials and further, limits of acceptance must also be stated clearly in respect of all factors. Following information will help the supplier to understand requirements from a quality standpoint.

1. Classification of quality characteristics

2. Acceptable quality level(AQL)

3. Inspection level

4. Method of checking For the supplier quality assurance to be effective, the system should be so designed that it does not merely act as a tool for supplier selection, rather it should be defect-prevention oriented.

Vendor Rating

Various systems of vendor rating are in vogue. More refined and more accurate the plan is, more difficult it becomes to administer. Hence a compromise is necessary for successful implementation. The plan prescribed here is a composite plan which considers all the essential factors so as to ensure the buyer, the required product quality standards at economic cost and in scheduled time. The three essential factors namely quality, service form the basis. The weightage given would vary according to purchasing manager.

The following definition indicates the scope of these factors in overall rating.

Quality

It is the measure of material, not in conformance with the given specifications. This takes into takes into account the number of defectives as well as seriousness of defects.

Service

Measures the promptness of vendor in keeping schedules of delivery, removing of rejected materials and nature of response to other activities.

Price

It is the measure of price differential for the same product supplied by different suppliers. Thus, in order to determine a vendor?s overall rating each factor is given weightage in terms of its importance to vendee and then these are multiplied by vendor?s final ratings. To compare between two or more suppliers the weightage factors must, however be constant, for all suppliers, supplying a particular material.

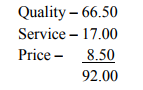

Eg. Suppose (a) Quality standard as 100per cent minus the percentage of defects (b) service is determined by 100 per cent minus 5 per cent for each failure (c) Price is evaluated by the lowest price quoted divided by the price paid. Thus, if price paid to vendor A was Rs. 100, the lowest offer being 85, the delivery was affected in 3 installments and rejection rate was 5 per cent, the overall rating for vendor A would be

Evaluating a new vendor

On completion of all potential supplier?s list, the buyers next step is to evaluate the individual supplier. By a process of elimination, a select list of supplier is prepared and negotiation starts. The list should be broad enough to bring in competition with respect to:

These may be followed by plant visits, enquiry with regard to financial competence, past services, etc. Even then, in some cases, the buyer may not be able to make a selection, but must develop a new source of supply. Such a necessity arises in many cases of growing industrial endeavours where existing supplier cannot satisfy buyer?s need.

Supplier's audit

The Q.C. department should have responsibilty together with other relevant departments for approving suppliers who can reliably supply starting and packaging materials that meet established specification.

Before suppliers are approved and included in the specifications they should be evaluated. The evaluation should take into account a supplier"s history and the nature of materials to be supplied. If an audit is required, it should determine the supplier"s ability to conform with GMP standards for active pharmaceutical ingredients.

Choosing Vendors

The purchasing department nearly always decides which company to buy from. Equipment buying is an exception, so are some trademark items. To choose vendors intelligently you ought to know which thinfgs are sold bby which company. This can be learnt from salesman who calls on you, from advertisements in technical and trade magazines, from trade directories and buyer?s giude. These should be a file of catalogs of vendor companies and their price and discount lists. Big companies keep a detailed file of vendor performance. For each vendor they keep a record showing the orders he got, price, service, delivery, quality information that will decide whether to choose him next time. While developing vendor, you should look at it overall. Price is important, though it is only a single thing to consider when picking vendors. Can and will the vendors deliver the order on the time? Will the material pass inspection after they get here? If they don"t, will the vendor fix things up right away without argument.

Schedule change

If you want to push through a rush order or cut your order, can he or will he take care of you? How about service of somethingn goes wrong? Will the vendors extend your credit for next 30 to 60 days? Price should never be forgotten but all these other aspects should also be noticed, while choosing vendors. A purchase group must constantly keep itself informed as to the best places to buy all items of materials required. In an ongoing situation, old established source will be, in all probability, the best source. However new sources should be investigated from time to time, and the performance of old sources evaluated periodically. If the npurchase requisition is for a new item, then from the list of potential sources, a selection should be made for enquiry by use of request for quotation.

Request for quotation

It is sent by purchasing group to all the selected possible sources of supply. It should be as complete as a purchase order except for the statement of price to be paid. It is upto vendor to submit price.

Selection of right source

Upon receipt of many quotations from the vendors, it then becomes the job of purchasing group to select the right source. Purchasing group is interested in thr reliability of prospective source of supply. Following questions may arise:

1. Will quality be maintained and shipments be made on schedule?

2. Does the vendor have adequate tools and equipments, trained personnel and finance to hand the contract?

3. What is the location of vendor?s plant in relation to purchaser?s plant?

4. What means of transportation are available between these two?

1. Selection of possible potential source of supply

-This process consists of selecting a fair number of vendors in accordance with established guidelines from whom quotations will be requested.

-For items, which are purchased frequently, the buyer usually has a few preffered suppliers from whom he purchases regularly

-For purchasing new items, refernce may be made to one or more of the following from which information can be obtained.

a) Catalogues

b) Trade Journals

c) Advertisements

d) Trade Exhibitions and fair

e) Trade Directories

When considering a potential source of supply, buyer should consider

i. Whether to purchase from local market or further field

ii. Whether to buy from single vendor or several vendors at time

iii. Whether to purchase directly from manufacturer or through wholesalers

2. Making request for quotations

Requets for quotation is made on prescribed quotation form to all selected sorces of supply

-The requets is not a purchase order, rather it is merelyan enquiry to know whether the vendor can supply the desired material by specified date and if so, at what rate?

-Quotation from contains terms and conditions under whichbuyer would like to purchase the materials.

3. Receipt analysisof quotation After receivinga number of quotations from different suppliers ther are studied and a comparative statement of rates and other terms and conditions mentioned in quotation is prepared.

4. Selection of right source of supply The comparative statement prepared serves a good guide in selecting the right source of supply. Other questions which might also be given thought are:

a. Will vendor maintain quality?

b. Will vendor supply material in time?

c. Does the vendor have adequate facility to handle contract?

d. How far the vendor plant is situated?

5. Issuing purchase orders

After selecting right supplier a purchase order is dispatched to him. The ourchase order constitutes a legal document and it serves as the vendor"s authority to ship the materials and bill the company.

-A purchase orderonce accepted by the vendor constitutes a contract for delivery of the article in accordance with the terms of purchase agreement.

-Purchase order is executed in six copies

i. 2 copies go to supplier. One he preserves and one signed and returned back.

ii. 1 copy goes to accounts section

iii. 1 copy goes to purchase service to follow up the order

iv. 1 copy sent to receving department

v. Last copy kept in files of purchasing department

6. Follow up and expediting the order

After placing the order purchase service section maintains contact with vendors in order to:

a) Obtain information as to the progress of the order

b) Ensure that delivery date will be met

c) Take corrective actions so that the materials can reach the plant as originally planned

7. Analysing receiving reports and processing discrepancies and rejections

- Receiving reports are the records of what has been actually received

- Receiving reports are compared with purchase order to find discrepancies i.e. variation in quantity, price, etc.

- Discrepancies found should be reported to supplier

- Before returning the material rejected during insepection, it is necessary for buyer to get vendor"s authorization for return and replacement.

8. Checking and approving vendor's invoices for payment

Invoices should be checked to ensure that

a) The correct material ( in quantity and quality)

b) Material has been supplied at agreed price and

c) Agreed discounts has been given

After confirming the above, payment is made to the vendor for the value of goods received.

Vendor approval

Objective: To provide a system to evaluate suppliers who supply material (raw and packing material) conforming to specified requirements. Procedure:

1) It is primary responsibility of purchasing department to establish and qualify a supplier

2) Wherever possible, purchasing should be from the manufacture rather through an agent. When an agent is used and if original manufacturers are not identified and if the material is not in original containers, additional controls must be instituted.

3) Written specifications shall be established in co-operation with production and Q>C> department.

4) Purchase orders shall include the specification or refer to a specification in the document provided to supplier

5) New vendor shall be required to meet the same specification as older vendors. They will also be required to supply appropriate samples and documentation to quality control prior to acceptance as an approved vendor.

6) For active ingredients supplier is to be audited initially and at periodic intervals. Thereafter, it is only to ensure that adequate process controls are in place for consisting of production and that the suppliers meet the GMP requirements. The need to audit and its frequency will be determined by suppliers past quality, history and nature of its suppliers. The suppliers certificate of analysis should be received for each batch of raw materials received. It is to be reviewed by Q.C. The performance of key suppliers should be monitored via rending to test data and reject/rework. Corrective action must be taken for unsatisfactory supplier performance.

7) It is the responsibility of purchase department keep the approved vendor list current.

8) Approved vendor list contains:-

a) Vendor?s name

b) Product supplied by vendor

c) Specification approved date: by QA, QC, production and purchasing department

d) Vendor approval date

e) Comments for additional information

Vendor Vendee Relations

Vendor or supplier is an important part of an organization. It is the basic objective of materials management to cultivate and maintain good relationship with supplier. Corporate plans are drawn up on the premise that materials and supplies will be forthcoming at right time, in right quality and proper quantity for which it is essential to have good vendor vendee relations. Purchasing plans are made successful only with suppliers? co-operation and goodwill. In case of emergencies and where actual material needs deviate substantially from anticipated initial requirements, a good vendor-vendee relation plays on important role. Even suppliers with a proven track record sometimes fail to keep delivery promises and not meet quality requirements always, due to some unavoidable reasons such as difficulties in manufacturing plants, labour trouble, transportation, etc. Purchasing department probably has more outside contacts with firms and individuals and buyer has the chance to enhance reputation and goodwill of his company especially by creating and maintaining good relationship with vendor.

Conclusion

It is important to have a good vendor development plan in a company. Vendor approval, vendor rating should be carried out periodically and if need arises, companies should change the vendors and approve vendors who can serve the company in a better way. It is equally important to have a good vendor vendee relations which helps companies to procure materials at right time in right quantity and at right price.

References:

1. Amrine Harold T., Ritchey John A., Hulley Oliver S.,Manufacturing Organization and Management, 4th edition, pg: 250-253

2. Khanna O.P., Industrial Engineering and Management, Revised First edition, Pg: 23.9-23.11

3. Datta A.K., Materials ManagementProcedures, Text and Cases, 2nd Edition, pg: 88-104

4. Mohammad Ali and Gupta Jyoti, Drug Store and Business Management, pg: 82

5. Alexander, Cross and Hill, Industrial Marketing, pg: 93-101

6. Shah D.H., SOP guidelines Straight and Simple, pg:409

7. Moore, Manufacturing Management, pg: 725-726 V

|

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License