IJCRR - 3(6), June, 2011

Pages: 77-83

Print Article

Download XML Download PDF

VALUE ADDED PRODUCTS OF TOMATO AND ITS QUALITY CHARACTERISTICS

Author: V.Saradha Ramadas, T.Thilagavathi

Category: Healthcare

Abstract:In India, nearly 7.1 million tones of tomato are produced annually from an area of 5.4 lakh hectares. Tomato known as poor man's apple are cultivated on 70000 acres of land in the state with an average yield to 140000 tones of tomatoes a day being produced. Excess tomato production leaves Tamil Nadu farmers disappointed (www.thehindu.com). Tomato is a good source of vitamins, minerals and other useful substances like fiber which are necessary for good health. Tomato contains lycopene and betacarotene pigment. Lycopene is one of the most important components in tomato as it has been found to have a vital role in protecting humans from various types of cancer including colorectal, prostate, breast, endometrial and lung. Value addition to tomato through processing can be brought about by converting them into value added products. Sun Drying is found to be one of the ways to provide antioxidant product at low price to the community. Hence, tomato was dried and developed the various products using dried tomato and dried peel.

Keywords: Tomato, Cultivation, Lycopene, Drying

Full Text:

INTRODUCTION

The top five leading fruit-producing countries are the United States, China, Turkey, Italy and India. Tomato production has been observed in 144 countries. The total global area under tomato is to the tune of 46.16 lakh hectares and the global production is to the tune of 1279.93 lakh tones. The major country China had a fruit production of 30,102,040 mt in 1,255,100 hectares. India accounts for only 8.6mt while China, the top producer, recorded an output of 33.7mt (FAOSTAT Database, 2004). In India, nearly 7.1 million tones of tomato are produced annually from an area of 5.4 lakh hectares. Tomato occupies second position amongst the vegetable crops in terms of production. On an average, about 10,800 tones of tomatoes are exported annually from India. Tamil Nadu occupies seventh position in production of tomato among the state. Tomato occupies around 0.25 lakh hectares in the state with an average yield of 12, 500kg per hectare and an annual production of annual three lakh tones. Tomato known as poor man‘s apple are cultivated on 70000 acres of land in the state with an average yield to 140000 tones of tomatoes a day being produced. Excess tomato production leaves Tamil Nadu farmers disappointed (www.thehindu.com). Tomato is a fruit used as a vegetable mainly because of the low sugar content. It is consumed both in fresh as well as processed forms. Tomato varieties are now available with double the vitamin-C, 40 times more vitamin-A, high levels of anthocyanins and 2-4 times more lycopene compared to that in traditional varieties. Tomato contains over 80 nutrients beneficial to human (Potty, 2009) Tomato is a good source of vitamins, minerals and other useful substances like fiber which are necessary for good health. Tomato contains lycopene and beta-carotene pigment. Lycopene is one of the most important components in tomato as it has been found to have a vital role in protecting humans from various types of cancer including colorectal, prostate, breast, endometrial and lung. Being a powerful antioxidant it has the ability to protect living cells and other structures in the body from oxygen damage and maintain DNA integrity in white blood cells. Lycopene is also believed to be able to activate cancer preventing phase 11 enzymes. There is another view, which gives credit to other components present in tomato along with lycopene for the anticancer activity of the fruit. Potty (2009) emphasized that lycopene is also linked to improve skin health by virtue of its ability to protect against undesirable UV ray exposure. (www.indiaagronet.com) Value addition to tomato through processing can be brought about by converting them into various products like tomato ribbon chips, rice and sago tomato vadagam and sweet tomato. The simplest and inexpensive method of processing tomato is drying. This can be achieved by processing the tomato by simple techniques and try to improve the shelf-life of the tomatoes. Thus the tomato products can be made available even in the off-season. Keeping these in mind the present study is focused with the following objectives. To

- Develop an economically viable product to manage tomato wastage and

- Observe the shelf-life and analyze the selected nutritional quality of the developed products.

METHODOLOGY

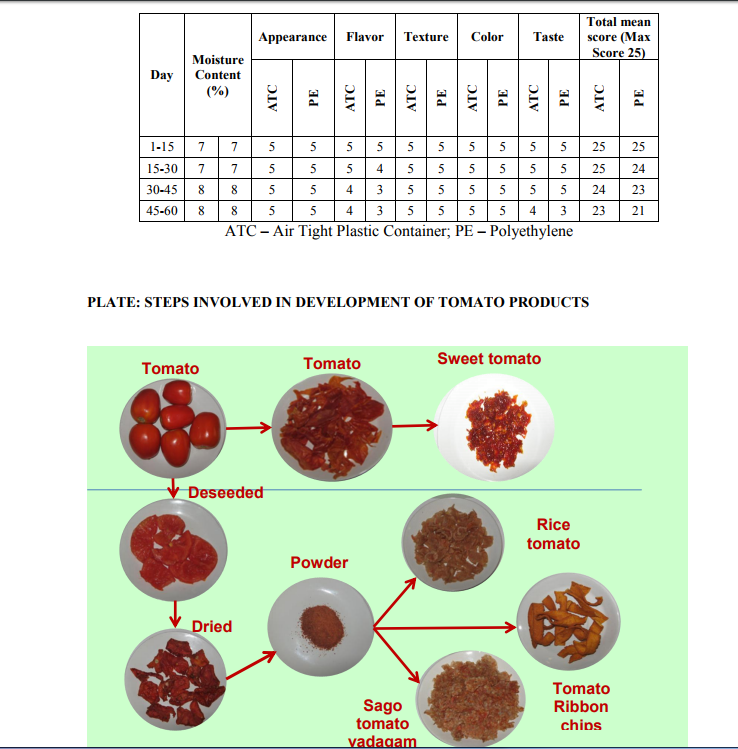

Sun-drying is an ancient method used in Indian households to dry fruits and vegetables. The removal of moisture from any substance is called dehydration. If the moisture in fruits and vegetables is reduced to a certain level by drying method, the shelf life can be increased. It is found to be one of the ways to provide antioxidant product at low price to the community. Hence, tomato was dried and developed the various products using dried tomato and dried peel. The steps involved in drying of tomato and list of products developed are shown in Plate I.

1. Drying of tomato: The variety of tomato selected for the powdering was country tomato (Namdhaari) which is available in the selected area. Tomato was washed swell, deseeded and dried in the sunlight. The dried tomatoes were powdered. Tomato products were developed and standardized using the dried tomato powder. Products like sago tomato vadagam, rice tomato vadagam and tomato ribbon chips were developed using the tomato powder.

2. Drying of peel: In order to make use of the peel the tomato was washed, blanched and peeled out the skin. The peel was sun dried and used for the product development of kulkanth. The tomato pulp, after removing the peel was used for the preparation of tomato sauce and pickle. Preservative was added to improve the shelf life of the tomatoes. Vinegar is used to develop a product. The concentration of vinegar in finished product should not be less than two per cent in order to ensure good result.

A) SENSORY EVALUATION OF DEVELOPED PRODUCTS

Sensory evaluation of all the developed products was done by a group of 20 selected panel members using a score card with the criteria of appearance, flavor, texture, color and taste. The panel members evaluated each sample on a specific scale for a particular characteristic indicating the rating of the samples. In order to identify the best quality product the mean acceptability scores were calculated.

B) ANALYSIS OF NUTRITIVE VALUE OF THE DEVELOPED PRODUCT

Since tomato is a good source of vitamin C and the pigment lycopene the analysis of these nutrients was done with the help of Post Harvest Technology Centre, Tamil Nadu Agricultural University, and Coimbatore. The major nutritive content of lycopene and vitamin C were analyzed in raw tomato, dried tomato powder and the products developed using dried tomato powder and the dried tomato peel. Dye method was followed for analyzing lycopene and vitamin C in fresh as well as processed tomato product and procedure followed for the analysis are given in Appendix III.

C) OBSERVATION OF SHELF LIFE OF THE DRIED TOMATO

All the developed products were stored in polyethylene cover and in air-tight plastic container for 60 days at room temperature. Quality of the stored products in terms of organoleptic quality and moisture content were assessed for every 15 days till two months. Hot air oven method was followed for finding out the moisture content in dried tomato powder. In order to ensure the quality of the dried tomato powder and product developed by using dried tomato powder and tomato peel, observation was made to assess whether the product is free from insect, fungal in mold growth over a period of 60 days.

RESULTS OF THE STUDY

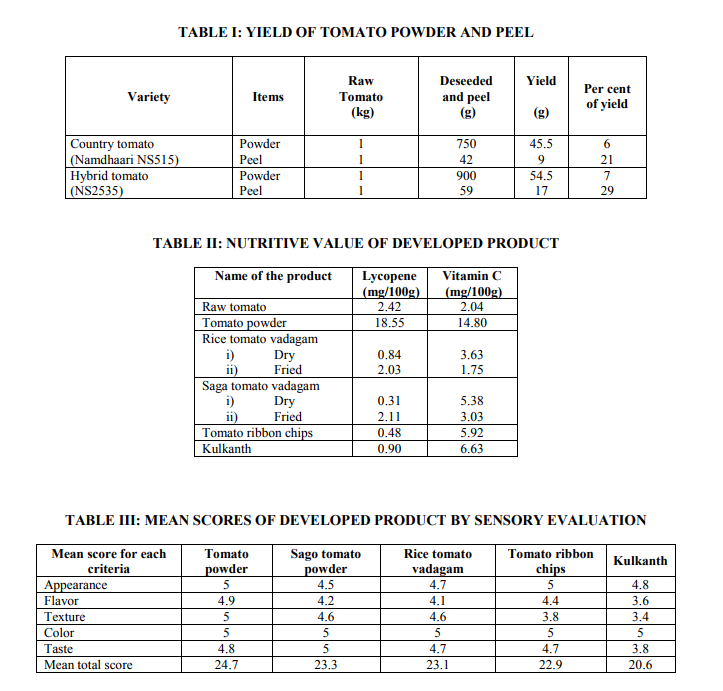

1. Yield of tomato powder and peel

Yield of tomato powder and peel is shown in Table I. The study revealed that a yield of six and seven per cent of tomato powder was obtained respectively from one kg of country and hybrid tomato and there was not much difference between the two varieties. The yield of tomato peel was found to be 21 per cent and 29 per cent respectively in country and hybrid tomato since the quantity of moisture content in peel was very much less than the tomato pulp. The yield of tomato powder from one kg of country tomato was 45.5g whereas hybrid tomato was 54.5g. The yield of tomato peel from one kg of country tomato was 9g whereas hybrid tomato was 17g. Aeration sun-drying (ASD) was tried for the preparation of tomato powder. From one kg of fresh tomato 50-55g of dehydrated powder was obtained with desirable quality. The overall acceptability score was found to be 8.3 on 9- point hedonic scale. The cost of drying was Rs.1.23 per kg (Gupta et al., 2006).

2. Nutritive value of developed product

Table II predicts the lycopene and vitamin C value of the developed product using the dry tomato powder. Raw tomato contains 2.42 and 2.04mg of lycopene and vitamin C respectively whereas tomato powder had 18.55 and 14.80mg of lycopene and vitamin C respectively in 100g due to loss of moisture content. The Polychemical Information Center states that cooked tomato based foods have greater health benefits, compared to uncooked, because the heating process makes all carotenoids (including lycopene) more easily absorbed by the body (http://recipes.suite101.com). The tomato powder had 14.80mg of vitamin C per 100g whereas the dry vadagam containing 30g of tomato made with rice and sago had 3.63 and 5.38mg of vitamin C per 100g respectively. The vitamin C content of dry and fried tomato vadagam made with rice and sago was found to be less than the dry tomato powder. However, frying also further degraded the value of vitamin C content. This is also proved by the study of Murator et al. (2008). He stated that temperature was directly related to ascorbic acid loss.

3. Sensory evaluation of developed product

Table III shows the sensory evaluation of developed products. Sensory evaluation is done for all products which scored, 4.9, 4.7, 4.6, 4.5 and 4.1, tomato powder, sago tomato vadagam, rice tomato vadagam, tomato ribbon chips and kulkanth. Tomato powder scored high value among the developed products. This organoleptic score indicates that the dry powder and the product developed using tomato powder were highly acceptable as the total mean score was ranged from 20.6 to 24.7 out of 25 scores. Tomato ketchup was prepared using seven different recipes and they are explored for organoleptic evaluation to select the best recipe along with recovery and processing cost. It was found to be best in terms of recovery cost and organoleptic scores (Charusinghal et al., 2005).

4. Shelf life of dry tomato powder

Table IV reveals that the quality of dry tomato powder in packed in polyethylene cover and airtight plastic container for two months. Shelf life of the tomato powder was assessed by sensory evaluation and found out its quality over a period of 60 days. Shelf life of the dry tomato powder prepared by using dried tomatoes was assessed over a period of two months. Quality of the packet products were checked for every 15 days till two months. The moisture content of the tomato powder not changed up to one month but after the end of 45 days, one per cent of moisture has been increased. The maximum of mean score of five was awarded for the appearance, color, texture, flavor and taste for the dry tomato powder over a period of 60 days by the panel members. This indicates that the powder stored in air tight plastic containers and polyethylene cover showed no difference indicating the shelf life of the products is at acceptable standard. There was no insect, fungal or mold growth till 60 days. The study can be extended further to evaluate how long the tomato powder is safe without any spoilage. There was not much difference between the materials air tight plastic container and polyethylene pack used for storing tomato dry powder and in both the storage it was safe over a period of two months.

DISCUSSION

It is noted that the yield of tomato powder from one kg of country tomato was 45.5g whereas hybrid tomato was 53.5kg. The yield of tomato peel from one kg of country tomato was nine grams whereas hybrid tomato was 17g. The study indicated that six to seven per cent of dried tomato powder was the yield from both varieties, 21 per cent of dried tomato peel was the yield from the country tomato, whereas 29 per cent of yield was derived from hybrid tomato. Raw tomato contains 2.42 and 2.04mg of lycopene and vitamin C per 100mg. The lycopene and vitamin C content in 100mg of tomato powder was 18.55mg and 14.80mg respectively. The difference between raw and dried tomato vadagam may be due to loss of moisture content. Rice tomato vadagam dry contains 0.84mg and 1.75mg of lycopene and vitamin C respectively per 100g whereas 2.03mg and 3.63mg of lycopene and vitamin C in 100g of fried vadagam. Sago tomato vadagam contains 0.31mg and 3.03mg per 100g in dry whereas 2.11mg and 5.38mg of lycopene and vitamin C in 100g of fried vadagams. Tomato ribbon chips contain 0.48 and 5.92 mg of lycopene and vitamin C per 100g. Kulkanth made with tomato peel contains 0.90 and 6.63 mg lycopene and vitamin C per 100g. The mean total score for the products sago tomato powder, rice tomato powder and tomato ribbon chips had a score of 23 and found to be highly acceptable. The moisture content of the tomato powder not changed upto one month but after the end of 45 days, one per cent of moisture has been increased. The shelf life study revealed that when dried tomato powder is stored in polyethylene cover and air-tight plastic container for one month, they scored 25. Though after 30 days, there is slight difference in flavor and taste and scored 23 and the tomato powder, the products developed were acceptable at the high level.

CONCLUSION

Thus, the study will promote employment opportunities to rural farmers, reduce tomato wastage, develop new value added product and available during off-season and raise the standard of living of rural population.

ACKNOWLEDGEMENT

The investigator extends her heartful thanks to Post Harvest Technology Centre, Tamil Nadu Agricultural University, Coimbatore for providing all amenities needed for the successful conduct of the study.

References:

1. Gupta, S., Ghuman, S.S. and Sandhu, K.S. Preparation of tomato powder on small scale, Journal of Food Science and Technology (2006), 43(1), 31-33.

2. Charusinghal, Singh P. and Singh, J.P. A study on techno-economic analysis of recipes for processing of tomato ketchup, Beverage and Food World (2005), 32(5), 24-25.

3. Muratore, G., Nobile, M.A.D., Buonocore, G.G., Lanza, C.M. and Asmundo, C.N. The influence of using biodegradable packaging fibres on the quality decay kinetic of plum tomato, Journal of Food Engineering (2005), 67(4), 393-399.

4. Muratore, G., Rizzo, V., Licciardello, F. and Maccarone, E. Partial dehydration of cherry tomato at different temperature and nutritional quality of the products, Food Chemistry, (2008), 111(4), 887-891.

|

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License