IJCRR - 3(9), September, 2011

Pages: 180-185

Print Article

Download XML Download PDF

COMPARATIVE ANALYSIS OF VAPOUR JET REFRIGERATION SYSTEM WITH WORKING FLUID

R134A & R410A

Author: Sandeep Kashyap, R.C. Gupta

Category: Technology

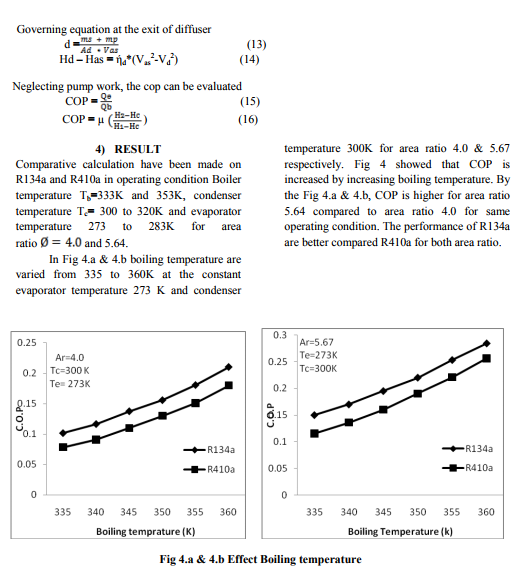

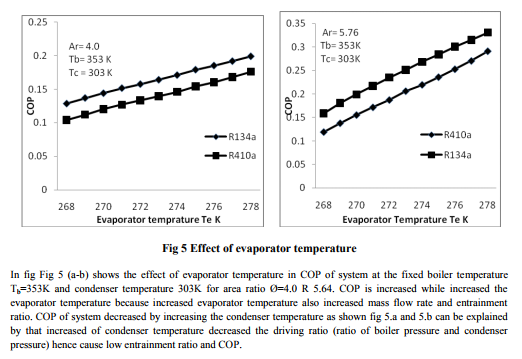

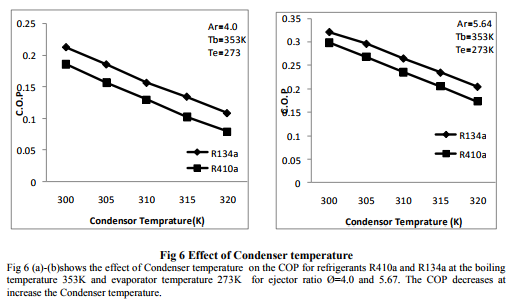

Abstract:This paper discuss, the performance of vapor jet refrigeration system with working fluid R410a and

R134a.The analysis based on one dimensional mathematical model. A performance comparison is made

on various operating condition and ejector area ratio. These operating conditions are boiling temperature

(333 to 353K), Condenser temperature (300 to 313K) & evaporator temperature (268 to 278K) and area

ratio 4.0 & 5.67.The result shows that performance of jet refrigeration mainly depends on boiling

temperature and ejector geometry, the performance R134a is better than R410a.

Keywords: Ejector, simulation program, ejector geometry, performance

Full Text:

1) INTRODUCTION

At present, most of conventional refrigeration system based on vapours compression cycle which are driven by the high grade electrical energy. The most attractive feature of Vapour jet refrigeration system over the conventional refrigeration system that it can driven by the low grade thermal energy such as solar energy, waste industrial heat and geothermal energy. Compared to other renewable energy operated refrigeration system, ejector refrigeration system has more simplicity, reliable, long life, low initial and running cost. The main disadvantage of Vapour jet refrigeration system has lower COP compare to other refrigeration cycle such as absorption refrigeration cycle (1). The performance of ejector refrigeration system mainly depends on the thermodynamic property of working fluid. At initial stage ejector refrigeration cycles utilized the water as working fluid but other refrigerant may also provided the better performance for Vapour jet refrigeration cycle. In this study eco friendly refrigeration‘s are taken for different area ratio.

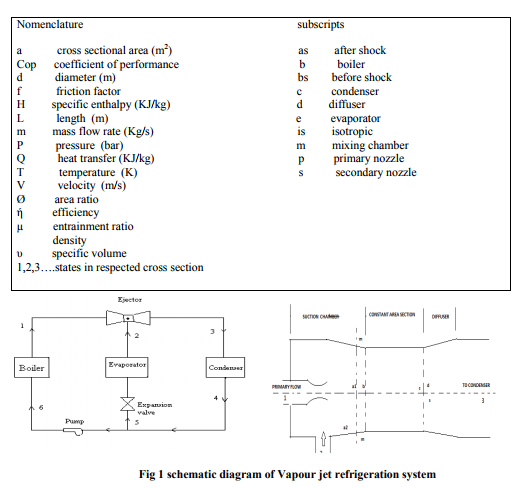

2) SYSTEM DESCRIPPTION

The Vapour jet refrigeration cycle is shown fig (1) which consists of boiler, condenser, evaporator, ejector, pump, expansion valve. Low pressure primary fluid enters into boiler where it absorbs low grade heat and converts into high pressure vapour. This high pressure saturated vapour moved into ejector where it expanded in the convergent- divergent nozzle and convert into high velocity stream, the pressure difference produce by primary fluid cause the suction of secondary saturated vaporized fluid from evaporator. Primary and secondary fluid mixed into the mixing chambered section and pressure increased due to shock waves by flow through the diffuser. High pressure fluid condensed into condenser by rejecting heat. A part of fluid pumped into boiler by the pump, remaining fluid entered into evaporated while passed though the expansion valve and produced the refrigeration effect.

5) CONCLUSION

Comparative analysis were made on Jet refrigeration cycles with working fluid R410a and R134a in same ejector geometry and same operating condition using one dimension modal. On based of study COP of ejector refrigeration cycle depends on ejector geometry, operation condition and property of working fluid. COP of system increased as boiler temperature increased while Cop is decreased when Compression ratio and condenser temperature increased. For different ejector ratio the performance of system are different but ejector ratio Ø= 564 at 353K have higher COP comparative other ejector ratio. For all area ratio and operating Condition the performance R134a is better than R410a.

References:

1. Kim DS. Infant Ferreia CA review- solar refrigeration option –a state of the art review (2008). 2.

K . Cizunga, A Mani, M. GRoll : Performance compression of vapour jet refrigeration system with environment friendly working fluids 2000).

3. A. selvaraju, A. Mani: Analysis of a vapour ejector refrigeration system with environment friendly refrigerants (2004).

4. Latra Boumaraf, Andre Lallemand: Modeling of an ejector refrigeration system operating in dimensioning and off dimensioning condition with the working fluids R142b and R600a (2008).

5. Jianlin Yu, Zhenxing Du: Theoretical study of a transcritical ejector cycle with refrigerant R143a.

6. JJ Henzier; Design of ejectors for single phase material system (1883).

7. J Fabri, R Siestrunk: Supersonic air ejector, 1998.

8. K Matsuo, K. Tasaki, K. Sasaguchi, H. Mochizuki: Investigate of supersonic air ejectors. Part 1: performance in the case of Zero secondary flow.

9. K Matsuo, K. tasaki, K. Sasaguch, H. Mochizuki: Investigate of supersonic air ejector. Part 2 Effect of throat area ratio in ejector performances.

10. L.T Lu, J. c Champoussin, E. Nahdi: Performance optimal et Utilisation Du systeme a ejecteur en production de froid.

11. H. P Schlag, Experimentelle und theoretische Untersuchungen Zur Berechung der Kennvon gasbetribenen Einphaseninjektoren und Gutaufgabeninjektoren.

12. B. J uang , et al, A 1-D analysis of ejector performance (1999)

|

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License