IJCRR - 3(10), October, 2011

Pages: 90-92

Print Article

Download XML Download PDF

PINEAPPLE PROTEINASES: AN EFFECTIVE OAK TASAR COCOON COOKING AGENT

Author: Y. Ranjana Devi, L. Rupachandra Singh, S. Kunjeshwori Devi

Category: General Sciences

Abstract:Tasar silk production is one of the major agro based industries playing an important role in the rural

economy of the NE states of India. The hard and compact oak tasar (Antheraea proylei J.) cocoons are

difficult to reel due to presence of high amounts of protein-tannin complexes. The chemical and

commercial enzymatic methods developed for reeling these cocoons has drawbacks like low reeling

performance, low fibre strength, high costs, low fuel efficiency and prolonged cooking time. In the

present investigation, an alternative enzymatic method using pineapple (Ananas comosus (L.) Merr. cv.

Queen) extract which is abundantly grown in the NE

C for one hour and

subsequent single silk filament reeling on an epprouvette machine and tensile testing on instron tensile

strength tester. Results indicated good reeling performances with fibre strength of 2.03 0.07 g/D.

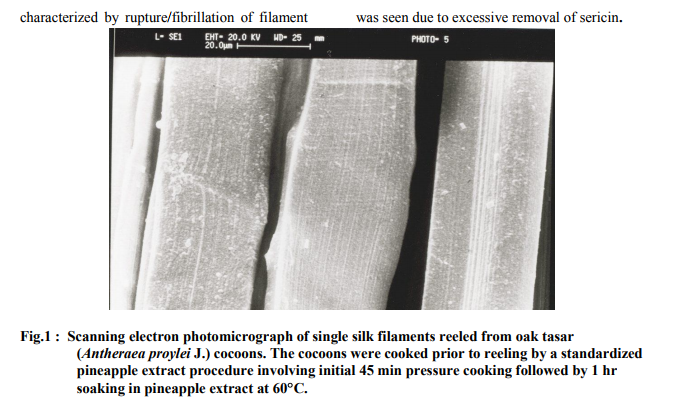

Scanning electron microscopic studies showed that the silk filaments were sufficiently free from the silk

gum sericin and no surface damage characterized by rupture/fibrillation of filament was seen due to

excessive removal of sericin. These results showed that pineapple extract which is rich in cysteine

endopeptidases can cleave the internal peptide bonds in an amino acid chain effecting partial

solubilisation of the proteinaceous silk gum (sericin) involved in binding the silk (fibroin) strands

together in silkworm cocoon.

Keywords: Proteolytic enzymes, Sericin, Fibroin, Single silk filament reeling.

Full Text:

INTRODUCTION

The oak tasar (Antheraea proylei J.) silkworm, the larvae of which feed on leaves of oak tree Quercus species (Family-Fagaceae) found extensively in the sub-Himalayan belt of India, is an important source of tasar silk (Singh and Singh, 1998). Tasar silk production is one of the major agro based industries playing an important role in the rural economy of the NE states. Due to hard and compact nature of the oak tasar cocoons and presence of high amounts of protein-tannin complexes in the form of proanthocyanidins, these oak tasar silk cocoons cannot be satisfactorily softened by boiling in plain water unlike the mulberry (Bombyx mori L.) silk cocoons (Pandey,1990). Generally the cocoons are cooked in presence of strong alkali agent, other harsh chemicals or commercial enzymatic preparations, however these methods are limited due to low reeling performance, high costs, low fibre strength, low fuel efficiency, complicated procedure and prolonged cooking time. Taking into account the abundant availability of pineapples in north eastern states of India, an alternative method for the oak tasar cocoon cooking based on the proteolytically active pineapple (Ananas comosus (L.) Merr. cv. Queen) extract was investigated for effective reeling performances.

RESEARCH METHODOLOGY

The cocoons produced by the oak tasar silkworm Antheraea proylei J. fed on Quercus serrata (Thunb.) leaves, hot air stifled for 6-7 hrs at 70ºC, and then stored for 2-3 months were used in the present investigation. These cocoons were cooked using a standardised procedure involving crude pineapple extract preparation as described. Thirty oak tasar cocoons (ten replications of three cocoons each) were wrapped in a coarse cotton cloth and subjected to 45 minutes pressure cooking at 15 lbs/sq inch pressure. The cocoons were then soaked in the pineapple extract at 60 C temperature in an incubator for 1 hour. The pineapple extract was prepared by homogenising 150 g of the fruit pulp (prepared by first detaching the crown and stem parts of the mature and yellow fruit and then slicing off the skin part) with 1 litre of distilled water and the resulting homogenate was strained through a coarse cotton cloth. The supernatant having high proteinase activity (Singh et. al., 2003) was used for softening of the oak tasar cocoons. At the end of soaking, cocoons along with the wrapper were taken out from the cooking medium, and then washed repeatedly with tap water until the associated brown colour and proteinase activity were washed out. The cocoons were then removed from the wrapper, semi-dried on blotting papers, deflossed, and then subjected to single filament reeling on an epprouvette machine. The silk fibres were subjected to tensile and elongation tests at 64% humidity and 25 C using Instron Tensile Strength Tester 6021 and also subjected to scanning electron microscopic examination using Scanning Electron Microscopic Model Stereoscan 360 of Cambridge Instruments.

RESULTS AND DISCUSSION

The reeling parameters for determining the reeling performances was evaluated as indicated by FAO - Silk Reeling And Testing Manual (1999). The following results on the reeling parameters were recorded as Mean of 30 cocoons ± S.D viz. (i) Number of ends feeding per cocoon (Number of breaks encountered by a cocoon while reeling) = 3.5 ± 1.1 (ii) Filament length (Length of reeled silk filament per cocoon in meters) = 676.7 ± 159.7 m (iii) Recovery % [(Filament weight/cocoon shell weight) × 100] = 69.7 ± 6.9 % (iv) Non- breakable filament length [(Filament length in meters × reelability%) / 100] = 193.5 m (v) Reelability % ( Number of reeled cocoons / Number of ends feeding) = 28.6% (vi) Denier (D) [( Total weight of reeled silk (g)/ Total length of reeled silk (m) × 9000)] = 6.8 ± 1.1 D (vii) Tenacity (g/D) and Elongation (%) as averages of twenty repetitions taking outer, middle and inner reeled filaments of the cocoon in more or less equal proportions = 2.03 0.07 g/D and 30.97 7.14 % respectively. The observations of the reeling parameters shows that the silk filaments obtained by using the standardised pineapple extract method has good reeling performances with better fibre strength which is needed for weaving efficiency of the yarn. Moreover, results of the scanning electron microscopic examination given in the form of photomicrograph in Fig.1. shows that the silk filaments were sufficiently free from the silk gum sericin suitable for optimum yarn reeling. At the same time, no surface damage

CONCLUSION

It can be concluded from the above observations that pineapple fruit pulp extract having proteolytic activity due to presence of cysteine proteinases, the most adundant among them being the fruit bromelain (EC 3.4.22.33) (Rowan and Buttle, 1994), have the potential to effect partial solubilization of the proteinaceous gum sericin involved in binding the silk strands (fibroin) together in cocoon, an essential process in the silk cocoon cooking and reeling. The pineapple proteinases find application in silk industry in general and tasar (non-mulberry) silk in particular as an effective cocoon cooking and reeling agent

ACKNOWLEDGEMENT:

Financial assistances from DBT, New Delhi, India in the form of project grant and DST, New Delhi, India in the form of FIST grant are gratefully acknowledged

References:

REFERENCES

1. Singh, K.C. and Singh, N.I. Biology and ecology of temperate tasar silkmoths, Antheraea proylei Jolly and Antheraea pernyi Guerin-Meneville (Saturniidae): a review. Ind J of Seri 1998 ; 37(2) : 89-100

2. Pandey, R.K. Why oak tasar cocoons are difficult to reel. Ind Silk 1990; 29(4) : 32-34

3. Singh, L.R., Devi, Y.R., Devi, S.K. Enzymological characterization of pineapple extract for potential application in oak tasar (Antheraea proylei J.) silk cocoon cooking and reeling. Electronic. J of Biotech 2003; 6(3) : 198-207

4. Lee, Y. W. Silk Reeling and Testing Manual, FAO Agricultural Services Bulletin no.136, Food and Agricultural Organization of the United Nations, Rome. 1999

5. Rowan, A. D. and Buttle, D. J., Pineapple cysteine endopeptidases, Methods in Enzymology (Barrett, A.J., Ed.), Academic Press, New York, 1994; 244 : 555-568.

|

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License