IJCRR - 4(18), September, 2012

Pages: 31-37

Date of Publication: 29-Sep-2012

Print Article

Download XML Download PDF

PARTIAL PURIFICATION AND CHARACTERIZATION OF DETERGENT TOLERANT CELLULASE FROM BACILLUS SP. KP8

Author: Dhairyawant Kushwaha, Harsh Dev Kumar, Gireesh Babu K

Category: General Sciences

Abstract:In this study cellulase producing Bacillus sp. KP8 was isolated from soil. The crude cellulase was found to possess 0.012\?moles/ml/min activity. The purification using Sephadex G-100 and DEAE-Cellulose lead to ~189 fold purity with 9.09% recovery. The enzyme was found to be optimally active at pH 5.0, 45ºC. The partially purified fraction displayed two proteins of ~45 kD. The kinetic studies revealed a Km of 2.85, while the Vmax was found to be 5.9. The non-metallo cellulase was detergent stable, possessing serine at its active site, sensitive to the presence of Mg+2, Mn+2, Hg+2, Cu+2, H2O2 and NaCl.

Keywords: Cellulase, Bacillus sp. KP8, Sephadex G-100, DEAE-Cellulose, SDS-PAGE

Full Text:

INTRODUCTION

Today, the enzymes are commonly used in many industrial applications and the demand for more stable, highly active and specific enzymes is growing rapidly. Cellulolytic enzymes play an important role in natural biodegradation processes of plant lignocellulose [1] by cellulolytic fungi, bacteria, actinomycetes and protozoa [2]. High cost of cellulase is mainly due to the substrates used in production and also the slow growth rate of fungi [3]. Bacteria, which has high growth rate as compared to fungi has good potential to be used in cellulase production. However, the application of bacteria in producing cellulase is not widely used. Bacterial cellulase usually lacks one of the three cellulase activities. However, cellulases produced by bacteria are often more effective catalysts. They may also be less inhibited by the presence of material that has already been hydrolyzed (feedback inhibition). Cellulose is the most abundant bio-polymer on earth; an estimated 7.5×1010 tons is annually synthesized through photosynthetic processes [4]. Found primarily in plant cell walls, cellulose is embedded in a heteromatrix composed of xylan, other hemi-celluloses and lignin. Specifically, cellulose is a linear, insoluble biopolymer composed of repeating β–Dglucopyranose residues linked by β-1, 4 glycoside bonds. In contrast to other glucan polymers, such as starch, the repeating unit of cellulose is not glucose, but cellobiose, a disaccharide. Cellulose exhibits a high degree of polymerization: the individual glucan chains, or cellodextrins, can reach lengths of greater than 25,000 glucose residues. The present study reports the purification and biochemical characterization of cellulase from Bacillus sp. KP8.

MATERIAL AND METHODS

Bacteria The Bacillus sp. KP8 isolated from the soil was used in the present study.

Production of cellulase

The Bacillus sp. KP8 was grown in 250ml nutrient broth with 0.5% CMC for 24h. The cells were harvested by centrifuging at 10,000 rpm for 3min and supernatant was used as the crude enzyme sample for cellulase assay and purification.

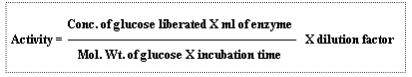

Cellulase Assay [5]

The 2ml reaction mixture of the enzyme contained 1ml of 0.1% CMC, 0.5ml of acetate buffer (25 mM, pH 5.0) and 0.5 ml of enzyme extract. The tubes were incubated at 450C for 10 min and added with 1ml of DNS. The tubes were further boiled for 10min, cooled and the absorbance was measured at 540 nm against the blank, added with DNS before the addition of enzyme. The concentration of glucose released was estimated by standard glucose curve. The activity was calculated according to the following formula;

Preparation of standard glucose curve

The different concentrations of glucose (0-100μg) were added into different tubes, by pipetting from the stock solution of glucose (1mg/10 ml). The mixture volume was made up to 2 ml by adding water followed by the addition of 1ml of DNS. The tubes were boiled for 10 min, cooled and the absorbance was read at 540 nm, against the blank (Fig 1).

Estimation of Protein [6]

The protein content of samples at every stage of purification was determined by the method of Bradford (1976). Bradford reagent was prepared accordingly. 20 mg CBB G-250 dissolved in 10 ml of 95% ethanol and 20 ml of orthophosphoric acid and made up to 200ml with distilled water. For the protein estimation, to 5ml of Bradford reagent 100μl of protein sample was added, mixed well and incubated for 5min at room temperature. The color developed was checked for its absorbance at 595nm against Bradford reagent as blank.

Standard BSA Curve

The standard Bovine Serum Albumin curve was prepared by taking the absorbance of different concentrations of BSA (0-100μg) mixed with 5 ml of Bradford reagent, at 540 nm. The graph was plotted taking concentrations of BSA on X axis and absorbance on Y axis (Fig 2).

Purification of Cellulase Precipitation of proteins by increasing the ionic strength

The crude protein supernatant was precipitated with ammonium sulphate (till 75% saturation) at 4 0C with constant stirring. The proteins were retrieved by centrifuging at 10,000 rpm for 10 min at 40C. The pellets of proteins were dissolved with minimum volume of 50mM Acetate buffer (pH 5.0).

Dialysis

The protein sample was loaded into the preactivated dialysis membrane (Himedia, cut off range 11 kD). The dialysis membrane was then hung into the 500ml of acetate buffer (5mM, pH 5.0). The dialysis was carried out for 8 h with 2 changes in buffer, at 40C. Gel filtration chromatography The Sephadex G 100 (Sigma-Aldrich) column (50X1cm) was run with 10 times the volume of acetate buffer (50 mM, pH 5.0). The 3 ml dialyzed enzyme sample was loaded and 25 fractions (2 ml) were collected. The fractions were analyzed for protein and enzyme activity. Ion-exchange chromatography The pre-activated DEAE-Cellulose (Bangalore Genei, Bengaluru) column (25X2 cm) was washed with 10 volumes of acetate buffer (50 mM, pH 5.0) and loaded with the pooled active fractions of gel filtration column. The cellulase was eluted by gradient buffer concentration (50-500 mM). The eluent was collected in 25 fractions of 2 ml each. The fractions were analyzed for protein and cellulase activity.

Characterization of cellulase

Polyacrylamide Gel Electrophoresis (PAGE)

The partially purified cellulase was further analyzed by SDS-PAGE [7]. The 10% gel was loaded with sample and molecular weight marker (medium range, Bangalore Genei, Bengaluru) and electrophoressed with a constant power supply of 100 V using electrophoresis buffer (Tris- 3g, Glycine- 14.3g, SDS- 2.0g for 1 liter). The gels were stained using silver staining technique. The enzyme found to be ~45 kD.

Biochemical characterization

Effect of pH on Cellulase Activity

The enzyme was assayed in presence of different pH buffers (50 mM), Citrate buffer (pH 4.0), acetate buffer (5.0 and 6.0), phosphate buffer (7.0) and tris buffer (8.0) were used.

Effect of Temperature on Cellulase

Activity Effect of temperature on cellulase activity was determined by incubating the reaction mixture at different temperature ranging from 37, 45 and 550C.

Kinetic studies of cellulase:

To study the kinetic properties of enzyme, the enzyme was assayed with different concentrations of CMC. The total volume of buffer and substrate in the test tube was made up to 1 ml. The Line weaver Burk plot was used to find the Vmax and Km.

Effect of Inhibitors and Metal ions and Inhibitors

The effect of various cellulase inhibitors and metal ions were analyzed. The enzyme was incubated for 10 min with different metals (20mM), inhibitors (2mM), H2O2 (30%), 1% SDS (Sodium Dodecyl Sulphate) 1M NaCl (Sodium Chloride) and assayed as mentioned above.

RESULTS

Cellulase activity The Bacillus sp. KP8 used in the present study could produce 0.012 µmoles/ml/min cellulase. Purification of cellulase By various steps of purification, the cellulase was purified by 188.88 folds with 9.09% yield (Table1). The SDS-PAGE analysis revealed presence of two bands ~45 kD (Fig.3).

Biochemical characterization Effect of pH on cellulase

The cellulase was assayed at various pH and found to be more active at pH 5.0 (Fig 4). Effect of temperature By incubating the reaction mixture at different temperatures, the highest activity was noted at 450C (Fig 5).

Kinetic studies

The LB plot (Fig. 6) drawn by the collected data indicated that the Km value as 2.85, while the Vmax was found to be 5.9.

Effect of metal ions and inhibitors on cellulase activity

Various metal ions, inhibitors and additives were tested for their effect on cellulase activity (Table2). The enzyme was completely inhibited by Mg+2, PMSF and EDTA. No additive could induce the activity.

DISCUSSION

This work demonstrated that Bacillus sp. KP8 isolate as good producers of cellulose. Cellulolytic species are found within the phyla Thermotogae, Proteobacteria, Actinobacteria, spirochaetes, Firmicutes, Fibrobacteres and Bacteroids. Of these, approximately 80% of the isolated cellulolytic bacteria are found within phyla Firmicutes and Actinobacteria [8]. The majority of the gram-positive cellulolytic bacteria is found within Firmicutes and belongs to the class Clostridia and the genus Clostridium. Although first described within Clostridium thermocellum, numerous other clostridial species have been shown to utilize a cellulosome as their cellulose degrading strategy. These bacteria are ubiquitous in anaerobic soil environments and include C. cellulolyticum, C. acetobutylicum, C. cellobioparum and C. papyrosolvens [9]. The cellulase was purified by 188.88 folds with a recovery of 9.09%. A major loss in the recovery was noticed during the gel filtration process. The SDS-PAGE indicated the presence of two proteins of ~45 kD, which have to confirmed for isoforms. The cellulase was optimally active at acidic conditions requiring moderately high temperature (450C). The enzyme was found to possess serine at its active site as it lost its activity completely in presence of PMSF. The enzyme was also found to be inhibited by Mg+2 and EDTA, indicating the non-metallo nature. The cellulase was detergent stable as it could retain 98% activity in presence of SDS, but not bleach stable and salt tolerant as it lost activity in presence of H2O2 and NaCl, respectively. The present work reports the bacterial cellulase, which has to be studied further for the suitability and applications in industry.

References:

1. Lynd, L.R.; van Zyl, W.H.; McBride, L.E.; Laser, M. Consolidated bioprocessing of cellulosic biomass: an update. Curr Opinion in Biotechnology 2005, 16(5), 577-583.

2. Olsson L., Hahn-Hagerdahl B. 1997. Fermentation of lingocellulose hydrolisates for ethanol production. Enzyme Microb. Technol. Vol. 18. P. 312–331.

3. Lynd, L.R.; Weimer, P.J.; van Zyl, W.H.; Pretorius, I.S. Microbial cellulose utilization: Fundamentals and biotechnology. Microbiology and Molecular Biology Reviews 2002, 66, 506- 577.

4. Monserrate, E.; Leschine, S.B.; Canale-Parola, E. Clostridium hungateisp. Nov., a mesophillic, N2-fixing cellulolytic bacterium isolated from soil. International Journal of Systematics, Evolution and Microbiology 2001, 51, 123-132.

5. Eriksson, K.E. and Petterson. B., 1972. In Biodeterioration of materials. J. Biotech. 2: 116.

6. Bradford, M.M. (1976) A Rapid and sensitive method for quantification of microgram quantities of protein utilizing the principles of protein dye-binding. Ann. Biochemistry. 32:248-253.

7. Laemmli, U.K. (1970) Cleavage of structural proteins during the assembly of the head of bacteriophage T4, Nature 227:680-685.

8. Bergquist, P.L.; Gibbs, M.D.; Morris, D.D.; Te’O, V.S.; Saul, D.J. Morgan, H.W., Molecular diversity of thermophillic cellulolytic and hemicellulolytic bacteria. FEMS Microbiology Ecology 1999, 28, 99-110

9. Desvaux, M. Clostridium cellulolyticum: model organism of mesophillic cellulolytic clostridia. FEMS Microbiology Reviews 2005, 29, 741- 764.

|

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License