IJCRR - 4(3), February, 2012

Pages: 74-80

Print Article

Download XML Download PDF

MICROBIAL, SENSORY AND NUTRITIONAL PROPERTIES OF CAULIFLOWER, PRESERVED BY

HURDLE TECHNOLOGY

Author: Jyoti Sinha, Ramesh Chandra

Category: Technology

Abstract:Objective: Develop suitable Hurdle treatment for preservation of cauliflower till 180 days of storage period. Methods: Fresh cauliflower were preserved by combinations of hurdles i.e. blanching (100\?C for 60 sec.), steeped into different concentrations & combinations of preservatives \? P0 (Control sample- fresh without treatment), P1( 8% Salt + 500 ppm Potassium metabisulphite + 100 ppm Sodium benzoate), P2 (10% Salt + 400 ppm Potassium metabisulphite + 200 ppm Sodium benzoate), P3( 12% Salt + 300 ppm Potassium metabisulphite + 300 ppm Sodium benzoate), P4 ( 8% Salt +0.3% Citric acid + 300 ppm Potassium metabisulphite + 300 ppm Sodium benzoate), P5 ( 10% Salt + 0.2% Citric acid + 400 ppm Potassium metabisulphite + 200 ppm Sodium benzoate) and P6 (12% Salt + 0.1% Citric acid + 500 ppm Potassium metabisulphite + 100 ppm Sodium benzoate), aseptically temperatures T1 (ambient- 30-37 \?C) & T2 (refrigeration- 5-7 \?C) for different time intervals i.e. 0, 30, 60, 90, 120, 150 & 180 days respectively. This preserved cauliflower were studied for their microbial, sensory & nutritional properties. Results: The treatments which remained microbial safe till 180 days of storage period were P4/T1 (YMC- 23.14count/gm), P5/T2(YMC- 17.71count/gm) & P4/packed into food grade polyethylene pouches and then stored at two different T2 (YMC - 8.43count/gm). Among these three, P4/T2 was scored highest in sensory, lowest in physical and highest in nutritional evaluation. Conclusion: Best hurdle treatment for preservation of cauliflower till 180 days of storage period was P4/T2.

Keywords: Hurdle , YMC, ppm

Full Text:

INTRODUCTION

India is a leading vegetable producing country in the world with the production of 113.5 million tons. The country is blessed with the unique gift of nature of diverse climates and distinct seasons, which makes it possible to grow a variety of vegetables. The overall productivity of vegetables is 14.4 tons per hectare. The production of vegetables has taken a big jump due to advent of many hybrid varieties. But our market strategy is not equipped with the handling of large quantity of vegetables as a result quantities of vegetables get spoil. Post harvest losses of horticulture crops are immense. It varies between 5-39% of the total production. The shelf life of perishable vegetables is very low. In brinjal, cauliflower and chilly post harvest losses were found to be high (9 Jayanthi 2005). Preservation involves action taken to maintain foods with desired properties or nature for as long as possible. It lies at the heart of Food Science and Technology and it is the main purpose of Food Processing (3Barnettand and Blanchfield, 1995). The Hurdle concept was first introduced by Prof. 10Lothar Leistner of Germany and his colleagues in 1978. The hurdle governs many preservation processes. Intense heat (F) preserves canned foods, low water activity prevents microbial growth in dried products, low pH is responsible for prolonged shelf life of fermented foods. This preservation technique is also called combination techniques or barrier technology or metodascombinados in Spanish, technologia degli ostacoli in Italian, Hurdle Technology in German. Potential hurdles for food preservation are – Temperature (High or Low), pH (High or Low), Water activity (High or Low), Modified atmosphere (Co2, N2 etc), Packaging (Vacuum packaging, aseptic packaging, edible coating etc.), Radiation (UV, microwave, irradiation etc), Preservatives (Class I and II). Hurdle Technology is a technology by which 2 or more hurdles are employed in a suitable combination and every hurdle is used at an optimum level so that damage to the overall quality of food is kept to the minimum. Hurdle Technology foods are defined as ?Products whose shelf-life and the microbial safety are extended by use of several factors none of which individually would be totally lethal towards spoilage or pathogenic microbes? (5Berwal, 1994).

Justification for research objective –

1) Through hurdle technology it become easy to preserve cauliflower at house hold level.

2) Make available the cauliflower at house hold level in off season.

3) Cauliflower preserved through hurdle technology are free from hazardous chemical which are used in cold storage to keep it like a fresh commodity.

Purpose – To preserve cauliflower through hurdle technology till 180 days.

MATERIAL AND METHODS

Cauliflower curds : The cords of cauliflower were procured from local market of Naini.

Chemicals used in preservation : Food grade (potassium metabisulphate, sodium benzoate and citric acid) chemicals were used.

Polyethylene pouches : Food grade pouches

Reagents used in analysis : Analytical grade reagents were used.

Method of preservation : First cauliflower head (white curds) after sorting, were cut into 5×3×3 cm. pieces with sharp edged stainless steel knife, then thoroughly washed in tap water and distilled water. After washing blanched at 100°C for 60sec. then steeped into different concentrations and combinations of preservatives – P0 (Control sample- fresh without treatment), P1( 8% Salt + 500 ppm Potassium metabisulphite + 100 ppm Sodium benzoate), P2 (10% Salt + 400 ppm Potassium metabisulphite + 200 ppm Sodium benzoate), P3( 12% Salt + 300 ppm Potassium metabisulphite + 300 ppm Sodium benzoate), P4 ( 8% Salt + 0.3% Citric acid + 300 ppm Potassium metabisulphite + 300 ppm Sodium benzoate), P5 ( 10% Salt + 0.2% Citric acid + 400 ppm Potassium metabisulphite + 200 ppm Sodium benzoate) and P6 (12% Salt + 0.1% Citric acid + 500 ppm Potassium metabisulphite + 100 ppm Sodium benzoate). Then aseptically packed into food grade polyethylene pouches and stored at two different level of temperatures- T1 (ambient temperature – 30 to 37 °C) and T2 (refrigeration temperatures – 5 to 7 °C) for different time intervals i.e. 0, 30, 60, 90, 120, 150 and 180 days respectively. This preserved cauliflower were studied for their microbial , sensory, physical and nutritional properties and data obtained after analysis were statistically analyzed.

Microbial properties: Yeast and mold was determined by Conventional method, ( 14Ranganna 2005).

Sensoryproperties : Sensory properties (color, flavor, texture and overall acceptability) were determined by 9 Point Hedonic Scale method ( 17Ranganna 2005).

Physical properties: Water activity was determined by using Water Activity Meter ( 2Aqua Lab Series 4TE- 2007). pH was determined by using pH meter (Electronic Corporation of India, Model 5652) as per procedure described in 12Ministry of Health and Family Welfare, Manual of methods of analysis of foods- Fruit and Vegetable Products , (2005).

Nutritional properties : Protein determined by Micro-Kjeldahl / Kjeltec method (16Ranganna, 2005), Vitamin A determined by method mentioned in (18Ranganna 2005), Vitamin C determined by 2, 6-dichlorophenol-indophenol visual titration method, ( 19Ranganna 2005) and potassium determined by Flame photometric method, ( 15Ranganna 2005).

Statistical analysis : Obtained data were analyzed for ANOVA ( 3 Way Classification) and critical difference (C.D.) technique, described by 8 Imran and Coover (1983). In statistical analysis, data used were average of replicates, total no. of treatments combinations were 14 – P0/T1, P0/T2, P1/T1, P1/T2, P2/T1, P2/T2, P3/T1, P3/T2, P4/T1, P4/T2, P5/T1, P5/T2, P6/T1, P6/T2 (where P0, P1, P2, P3, P4, P5 and P6 are different combination of preservatives and T1 and T2 are different level of temperatures, all are explained in Method of preservation). Level of significance was checked at 5% probability level.

RESULTS

Microbial properties of preserved cauliflower : Yeast and mold count of preserved cauliflower are given in Table 1. Treatments in which Yeast and mold count were found lowest with a storage period of 180 days are P4/T1, P4/T2 and P5/T2. There were significant difference between yeast and mold count of treated samples due to combination of preservatives and storage temperatures while there was not significant difference due to days of storage at 5% probability levels.

Sensory properties of preserved cauliflower : In sensory properties, results of only overall acceptability parameter was presented in Table 1. Treatment P4/T2 scored highest in overall acceptability with a storage period of 180 days. There were significant difference between overall acceptability scores of treated samples due to combination of preservatives and days of storage while there was not significant difference due to storage temperatures at 5% probability levels.

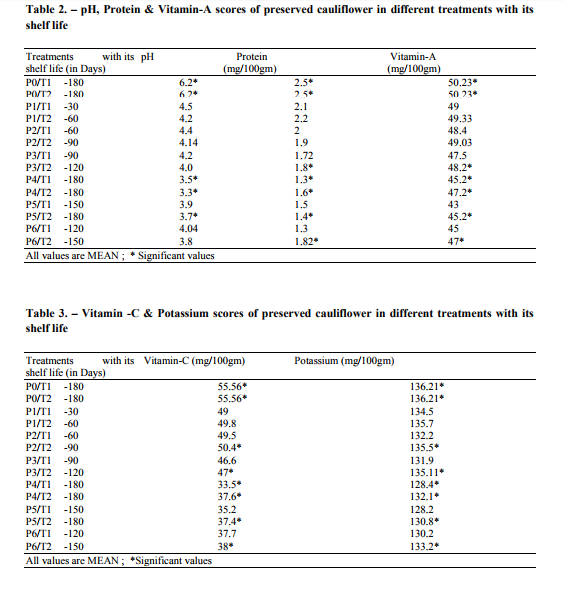

Physical properties of preserved cauliflower : From Table 1 - lowest water activity and from Table 2 - lowest pH were found in P4/T2 in a storage period of 180 days. There were significant difference between water activity and pH scores of treated samples due to combination of preservatives and storage temperatures while there was not significant difference due to days of storage at 5% probability levels.

Nutritional properties of preserved cauliflower : From Table 2 - highest retention of protein and vitamin A and from Table 3 - highest retention of vitamin C and potassium were found in treatment P4/T2 in a storage period of 180 days. There were significant difference between protein, vitamin A, vitamin C and potassium scores of treated samples due to combination of preservatives , storage temperatures and days of storage at 5% probability levels..

DISCUSSION

In microbial analysis, the increase in yeast and mold count was observed in all treatments at both the temperatures. In most of the treatments yeast and mold count were found above from the standard (as per 6 Food Safety and Standard Authority of India, 2006-Yeast/Mold not more than 100 count/gm) with increase in storage period, which may be attributed during addition of preservatives or during packaging which could have been a carrier of microbes. While in some treatments counts remained under control as per above mentioned standard till 180 days of storage, it might be due to better handling procedure or different concentration and combinations of class I and II preservatives and low temperature of storage. The results are in agreement of previous finding of 7Gould (1995), observed that the food preservation through hurdle technology cause interference with the homeostasis of yeast and mold. 1Alzamora et al. (1989), also noticed that yeast and mould counts remained below 100 cfu/gm.

during 4 months of storage of pineapple slices preserved through hurdle technology at 5°C. 11Lopez- Malo et al. (1994), preserved papaya through hurdles technology, found yeast and smold counts < 10 CFU/g during 5 months storage at 25°C. In sensory evaluation, the difference and decrease in overall acceptability scores was observed which may be attributed due to increase in microbial count with increase in storage period. But at the same time, treatments which remained microbial safe till 180 days of storage period were best rated in sensory evaluation. The results are in agreement of previous finding of 13Pruthi (1990), the vegetables like potatoes, carrot, cauliflower, cabbage, bitter guard, peas, mushroom and animals foods (meat, fish and poultry) preserved in an acidified sulphited brine solution through steeping can be used for pickling or home cooking after leaching out the salt and acid. 4Barwal et al. (2005) standardized the low cost and low energy processing technology for preservation of cauliflower involving different concentration and combination of salt (5-10%), potassium metabisulphite (0.2%) and citric acid (1%) after blanching. The preserved cauliflower was accepted in sensory evaluation after 90 and 180 days of storage by reconstituted in running water for half an hour and evaluated for the preparation of pickle and pakora. In physical test, the reduction in water activity and pH of preserved sample were found as compare to initial or fresh commodity. Reduced water activity and pH were found effective for long time storage. The results are in agreement of previous finding of 21Vibhakara et al.(2005), maintenance of pH< 4.5 helped in controlling multiplication and survival of spores and also helpful in achieving shelf stability. Low pH and water activity solutions are used as antimicrobial agent or as antioxidant to prevent browning, to reduce discoloration of pigments, and to protect against loss of flavor, changes in texture (23Wiley, 1994).

In nutritional evaluation, loss of nutrients were found in each treatments but on other hand better retention of protein, vitamin A, vitamin C and potassium were also observed in treatments of 180 days of storage period. The results are in agreement of previous finding of 20Srivastava and Kumar (2002), sulphur dioxide is widely used throughout the world in the preservation as it acts as an antioxidant and bleaching agent. These properties help in the retention of vitamin C, vitamin A and other oxidizable compounds. Sulphur dioxide with potassium metabisulphite (if added in the solution) helps to retain vitamin C content of the preserved material (22Verma and Joshi, 2000). Low pH and water activity solutions were also effective towards nutrient retention ( 23Wiley, 1994).

CONCLUSION

All the treatments combination were not effective for preservation of cauliflower till 180 days of storage period. Only 3 treatments - P4/T1, P4/T2 and P5/T2 were microbial safe till 180 days and among these 3, only P4/T2 was found best in sensory as well in nutrient retention in 180 days of storage period. ACKNOWLEDGEMENT I express my deep sense of gratitude for my advisor (Prof.) Dr. Ramesh Chandra, (Dean) Warner School Of Food and Dairy Technology, to all member of advisory committee - Dr. D.B. Singh, Dean of Horticulture Department, (Prof.) Dr. Sarita Sheikh, Dean of Halina School of Home Science, (Prof.) Dr. Sangeeta Upadhayay, Assistant Professor (Microbiology),Warner School Of Food and Dairy Technology, (Prof.) Dr. Ram Lal, Dean of Department of Statistics, Sam Higginbottom Institute of Agriculture, Technology and Sciences, Allahabad, for there sincere guidance, suggestions, constructive work and encouragement during the entire research work. Sincere thanks to Honorable Vice-Chancellor, Sam Higginbottom Institute of Agriculture, Technology and Sciences, Allahabad, for providing me necessary technical and financial facilities. I want to acknowledge the immense help received from the scholars whose articles are cited and included in references of this manuscript. I also grateful to authors / editors / publishers of all those articles, journals and books from where the literature for this article has been reviewed and discussed.

References:

1. Alzamora SM, Gerschenson LN, Cerrutti P, Rojas A M. Shelf-stable pineapples for long-term non refrigerated storage. J. Lebensm-Wiss. u. – Tech 1996; 22:233- 236

.

2. Sample Preparation and Taking a Reading. In: Operator‘s manual AQUA LAB 4TE, Water activity meter. Decagon Devices; 2007. p. 46-51.

3. Barnettend M, Blanchfield JR. What does preservation mean. Food Sci. Technol 1998; 9:93-12.

4. Barwal VS, Sharma R, Singh R. Preservation of cauliflower by Hurdle Technology. Food Sci and Tech 2008; 42(1):26-31.

5. Berwal JS, Hurdle technology for shelf stable food products. Indian Food Industry 1996; 13:40-43.

6. Ministry of Health and Family Welfare (Food Safety and Standard Authority of India) Part 4th New Delhi. Microbiological Requirements of Food Products. Appendix B, Table-4. 2006; p.665.

7. Gould GW. Interference in homeostasis. In: Whitten bury R, Banks JG, editors. Homeostatic Mechanism in Microorganisms. 3rd ed.: Bath University Press; 1995. p. 220.

8. Imran RL, Cover WB. Statistical analysis. In: A modern approach to statistics. 2nd ed. New York; 1983: p. 120.

9. Jayanthi M. Innovative solution to extent the shelf life of fruits. Processed Food Industry 2008; 9(1): 37-38.

10. Luthar L. Hurdle effect and energy saving. In: Downey WK, editors. Food Quality and Nutrition. 2nd ed. London: Applied Science Publishers; 1990. p. 553-557.

11. Lopez-Milo A, Palou E, Welty J, Corte P, Arias A. Shelf-stable high moisture papaya minimally processed by combined methods. International J. of Food Research 1995; 27(6):545-553.

12. Ministry of Health and Family Welfare (India). Manual of methods of analysis of foods: Fruit and Vegetable Products. New Delhi: Government of India; 2005; 6.

13. Pruthi J S. Physiology, Chemistry and Technology of Passion Fruits. In: Advances in Food Research. Vol. 12. 2nd ed. New York: Academic Press; 2000. p. 203-274.

14. Ranganna S. General instruction for microbiological examination. In: Hand Book of Analysis and Quality Control for Fruit and Vegetable Products. 2nd ed. New Delhi: Tata McGraw Hill Education Private Ltd New York; 2005. p. 646-655.

15. Ranganna S. Minerals. In: Hand Book of Analysis and Quality Control for Fruit and Vegetable Products. 2nd ed. New Delhi: Tata McGraw Hill Education Private Ltd New York; 2005. p. 127-128.

16. Ranganna S. Proximate constituents. In: Hand Book of Analysis and Quality Control for Fruit and Vegetable Products. 2nd ed. New Delhi: Tata McGraw Hill Education Private Ltd New York; 2005. p. 21-24.

17. Ranganna S. Sensory evaluation. In: Hand Book of Analysis and Quality Control for Fruit and Vegetable Products. 2nd ed. New Delhi: Tata McGraw Hill Education Private Ltd New York; 2005. p. 623-624.

18. Ranganna S. Plant pigments. In: Hand Book of Analysis and Quality Control for Fruit and Vegetable Products. 2nd ed. New Delhi: Tata McGraw Hill Education Private Ltd New York; 2005. p. 84-86.

19. Ranganna S. Vitamins. In: Hand Book of Analysis and Quality Control for Fruit and Vegetable Products 2nd ed. New Delhi: Tata McGraw Hill Education Private Ltd New York; 2005. p. 105-106.

20. Srivastava RP, Kumar S. Principles and Methods of Preservation. In: Fruits and Vegetable Preservation: Principles And Practices. 3rd rev. ed. International Book Distributing Co; 2002. p. 93.

21. Vibhakara HS, Manjunath SS, Radhika M, Gupta DK, Bawa AS. Effect of gammairradiation in combination preservation technique for stabilizing high moisture spice based vegetables. J Foods Sci and Techno 2007; 42 (5):434-438.

22. Verma LR, Joshi VK. Steeped preserved products. In: Verma LR, Joshi VK, editors. Post harvest technology of fruits and vegetables. Indian publishing Co. New Delhi; 2000. p. 861-867.

23. Wiley RC. Preservation of vegetables. In: Chapman and Hall editors. Preservation methods for processed refrigerated fruits and vegetables. 2nd ed. New York; 1994. p. 226-268.

|

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License