IJCRR - 4(4), February, 2012

Pages: 141-148

Print Article

Download XML Download PDF

HEAT MASS TRANSFER AND THERMOPHYSICAL ANALYSIS FOR DOUBLE SLOPE STEP TYPE SOLAR

STILL

Author: S.Kalaivani, S.Rugmini Radhakrishnar, B.Selvakumar

Category: Technology

Abstract:In this communication, an attempt has been made to find out the heat transfer coefficients such as internal and external heat transfer modes and thermophysical properties such as dynamic viscosity, density, thermal conductivity, latent heat of evaporation and saturated vapour pressure for active solar distillation system. It is observed that the distillate output (the yield) increases significantly with the top cover cooling study. Double slope step type solar still of area 1 m2 is constructed using a single piece of mild steel. Acrylic cover with 10\? slope ensures a very good transmission of solar radiation inside the still. The distillate water productivity is in the range of 1.758 litres to 1.805 liters per day for still performance study. Similarly the instantaneous efficiency for still performance study is in the range of 17.84% to18.25%.

Keywords: Solar Still, Heat Transfer Modes, Radiation, Acrylic, Distillate Yield, Efficiency

Full Text:

1. INTRODUCTION

It is a well known fact that fresh water is necessary for the continuity of all life. The global fresh water shortage, particularly in remote areas, presents an international problem. The problem is more severe in desert countries, particularly in India, where water shortage is a serious problem. In India, the urgent need for fresh water is concentrated in the coastal regions, which constitutes a considerable development area. Since the transportation of fresh water to these areas is difficult and not economic, desalination systems are essential. Many of these countries, however, enjoy an abundant and free solar energy with high intensity so that solar distillation is a promising way of supplying these regions with fresh water. H.P. Garg and H.S. Mann [1] indicated that about 26% of the heat input to the basin-type solar still is lost through its base, and an improvement of about 7% in the distilled water can be obtained per year by using sawdust insulation of 25 mm thick. Abdel-Salam et al., [2] studied the effect of insulation on the performance of unsymmetrical solar stills under steady state conditions. They concluded that a reduction in the thermal conductance of the still insulation from 4.0 to 0.4 W/m2 °C increased its productivity rate by 16.5% at a constant heat flow rate. Several research results were published where heat transfer coefficients are calculated theoretically for various operating conditions by M. A. S. Malik et al., [3]. They concluded that heat flows inside the still are calculated generally by assuming that transfer mechanisms such as convection and mass diffusion take place simultaneously and the total heat transfer rate is calculated by adding the individual quantities. Baum and Bairamov [4] found in an experimental solar still, operating under controlled conditions, that the evaporation and condensation processes are interrelated in such a manner that they intensify each other, hence evaluation of them separately may lead to errors. Comparison of a double basin solar still with that of single basin solar still was investigated by A.A. Al-Karaghouli and W.E. Alnaser [5] with different top cover angles. Numerical simulation for natural convection flows in a triangular cavity submitted to a uniform heat flux using the Control Volume Finite Element Method have been analysed by Ahmed Omri et al., (6). The study provides useful information‘s on the flow structure sensitivity to the governing parameters, the Rayleigh number and the tilt angle, on the thermal exchange. M. Boukar and A. Harmim [7] studied the parametric studies of a vertical solar still under desert climatic conditions. El-Nashar [8] modeled a hybrid system solar/MED, using solar collectors to produce the heating fluid (instead of LP Steam) to feed the first evaporation stage. Performance evaluation of a modified design of a single slope solar still was studied by Salah Abdallah et al., [9]. Results concluded that inclusion of internal mirrors improved the system thermal performance up to 30%, while step-wise basin enhanced the performance up to 18% and finally the coupling of the step-wise basin with sun tracking system gave the highest thermal performance with an average of 38%. The objective of the present study was to improve the performance of a traditional double slope solar still through a design modification: using step-wise water basin instead of flat basin. The modification can increase the solar still capability to capture more solar energy. System performance can be increased by proper utilization of the latent heat of condensation for further distillation. The daily distilled output may be increased by maximizing the temperature difference between the evaporating and condensing surfaces. This condition is achieved either by increasing the evaporation surface or decreasing the condensation surface temperatures. The former is increased by feeding thermal energy to the basin from an external source; the latter is decreased by flowing water uniformly over the outer surface of the glass cover.

2. Construction of Double Slope Step Type Solar Still:

Double sloped solar desalination unit with total evaporation area of 1m2 is made using galvanized iron sheet of thickness 24gauge. There are four trays each having basin area of 0.15 m x 0.70 m on each sides of the still. There is a center tray of basin area 0.23 m x 0.70 m. In order to avoid the leakages between the joints in trays and is made by using a single G.I. sheet. It is folded in such a way to form the steps. The sidesof each step basin trays are bent upwards to a height of 0.10 m. Base of the still are blackened with paint for good absorption of solar radiation.

The top cover is provided for the solar still using Acrylic sheet of 3 mm thickness. A slope of 10 is provided from the center of the basin to the end of basin to receive the direct solar radiation more nearly perpendicular to the absorbing surface. The Acrylic cover required for this slope is 0.74 m for each slope on both sides. The height from the basin and cover is maintained 0.10 m for all the step basins. The outer cover is made up of Wood of thickness 0.015 m. The dimension of outer cover box is 0.154 m x 0.80 m x 0.22 m respectively. Saw dust and glass wool makes the bottom and side insulation. A stainless steal water collection segment of dimension 0.80 m x 0.03 m x 0.04 m is placed at the end of acrylic cover on both ends of the stepped basin. A cross sectional view of double slope step type acrylic top cover solar still is shown in Fig (1).

3. Experimental Arrangement:

The double slope step type solar still unit is placed with an orientation in the North-South direction. The performance of the still has been studied for number of days and its readings on clear sunshine days have been recorded. The experimental study is started from 9am. The basin is filled with water of 15 litre of saline water. The pre-calibrated thermocouples are fixed at the appropriate places and it is connected to the digital thermometer to measure the air temperature (Ta), water temperature (Tw) inside the still and top acrylic cover temperature (Tg). A thermometer with an accuracy of 0.1 C is used to measure the ambient temperature (Tamb). Amount of total solar insolation (H) and the amount of distilled water collected at the outlet are recorded at regular intervals. A measuring jar is kept at the distilled water outlet and the collection is recorded at the regular intervals.

4. Heat and Mass Transfer Coefficients:

For the most normal range of operation for a conventional solar still, the most commonly used relationship to evaluate heat and mass transfer coefficients and it is proposed by R.V. Dunkle [10]. The study carried out by S. Adhikari et. al., [11] for verifying the applicability of Dunkle‘s relationships over a wide range of operating temperatures within a solar still reported that Dunkle‘s relationships behave well in the lower temperature ranges. So R.V. Dunkle‘s [10] relationship needs the modification in the higher ranges of temperatures. Thus they proposed a relationship for evaluating heat and mass transfer coefficients including higher temperature ranges as follows.

4.1 Internal Heat Transfer Rate at Inside the Still:

Heat transfer inside the still is predicted by using equation proposed by M.A.S. Malik et. al., [12]. Heat is transported inside the still by free convection of air. It releases its enthalpy upon air, which is coming in contact with the glass cover. The heat transfer per unit area per unit time due to convection is

here R1 and R2 are constants evaluated by fitting the saturation vapor pressure data in the range of interest to a straight line. In usual analysis of solar still, the water surface and the glass cover are considered as infinite parallel planes. Using Stefann‘s Boltzmann‘s constant, heat transfer per unit area per unit time due to radiation is given by

6. RESULTS AND DISCUSSION

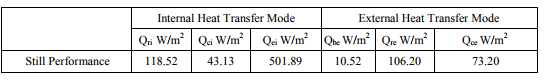

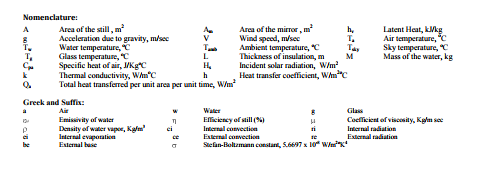

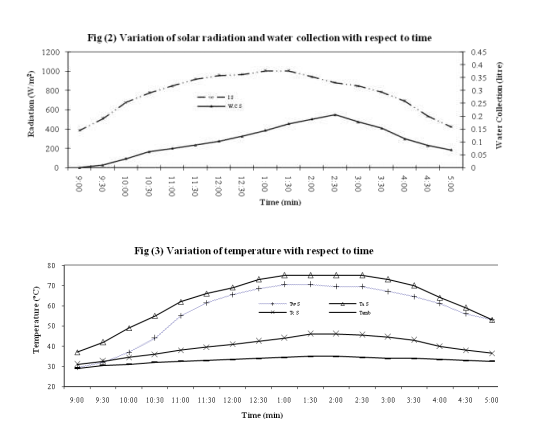

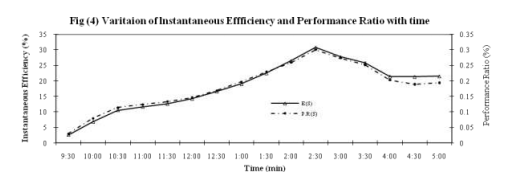

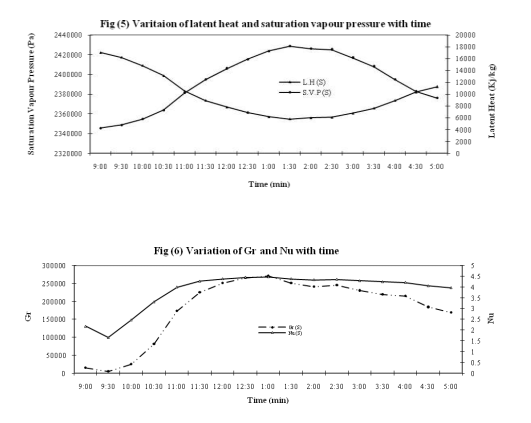

The performance of double slope step type acrylic solar still is analyzed on normal sunny days. The radiative heat transfer (Qrw), convective heat transfer (Qcw) and evaporative heat transfer (Qew) for internal heat transfer rates inside the still are predicted. Similarly heat transfer rates outside the still by conduction heat transfer (Qb), external heat transfer through radiation from the acrylic cover (Qra) and heat transfer from acrylic cover to atmosphere by convection (Qca) are also estimated. The instantaneous efficiency and overall efficiency are calculated for all the studies. The thermal conductivity of water is analyzed and it is observed in the range of 0.02672108 to 0.02886952 Wm-2 °C-1 . Dynamic viscosity of water is predicted and is in the range of 1.8578x10-5 to 1.9871x10-5 Nsm-2 . The density of water is predicted for the still under these experiments and it is observed as 1.164163 to 1.06586248 kgm-3 . Since thermal conductivity of an acrylic material is very low so the influence of condensation by the top cover is less difference in between top cover without and with cooling. Fig (2) shows the variation of insolation and distilled water collection with respect to time. Insolation increases linearly with time and reaches the maximum value from 12 p.m to 2 p.m and then decreases. Radiation received during this study is in the range of 386.46 W/m2 to 1002.39 W/m2 . The maximum distilled water collection is in the range of 10 ml to 206 ml. The amount of daily distillate yield collected is in the range of 1.681 liters/day to1.805 liters/day. Fig (3) shows the variation of temperature for water, air, top cover and ambient with respect to time for still. The maximum temperature rise in water, air, top cover and ambient are around 70.5 C, 75 C, 46 C and 35.5 C respectively. Fig (4) shows the variation of instantaneous efficiency and performance ratio of the still with respect to time. The instantaneous efficiency is increased according to the time. The variation of the efficiency observed during the study is in the range of 2.59 % to 30.76 %. Overall efficiency of the system for still performance is in the range of 16.16% to 18.22%. Performance ratio values are observed in the range of 3 % to 29.98 % for still performance study. This shows that the value of performance ratio increases according to increase in distillate output. Fig (5) shows the latent heat and saturated vapour pressure inside the still. It shows that the latent heat decreases initially with respect to time. It reaches low value at 1:00 p.m and starts to increase with respect to time because the temperature at this region is more. So it shows that the latent heat is decreased in this region at higher order of temperature. Most of incoming radiation is utilized for evaporation at this stage. Latent heat value is observed in the range of 2422073.45 to 2354675.86 J kg−1 . Saturated vapor pressure starts to increase with respect to time and it reaches the peak value at 1:30 P.M to 2:00 P.M. Saturated vapor pressure reaches maximum value when water collection is more and tends to decrease when water collection decreases. Saturated vapour pressure are predicted in the range of 4262.48 to 18111.53 Pa. Fig (6) shows the variation of Grashof number and Nusselt number with respect to time. Both Grashof and Nusselt number increases with respect to time. The Nusselt number value and Grashof number value is almost nearer to each other for both the studies. Grashof number is found to be around 5123.01 to 271519.10. Nusselt number values are observed in the range of 1.65 to 4.46 Heat transfer coefficients predicted under internal and external heat transfer modes for still performance is shown in table below:

References:

1. H.P. Garg & H.S. Mann, ?Effect of Climatic, Operational and Design Parameters on the Year Round Performance of Single-Sloped and Double Sloped Solar Stills Under Indian Arid Zone Conditions?, Solar Energy, Vol. 18, pp. 159-64, 1976.

2. M.S. Abdel-Salam, S.H. Soliman, M.A. Mohamad & H.M.S. Hussein, ?Effect of Insulating Materials on the Performance of Unsymmetrical (L-type) Solar Stills?, AlAzhar Engineering Third International Conference, Vol. 7, pp. 361-369, 1993.

3. M. A. S. Malik, G. N. Tiwari, A. Kumar, and M. S. Sodha, ?Basic Heat and Mass Transfer Relations?, Solar Distillation, a Practical Study of a Wide Range of Stills and Their Optimum Design, Construction and Performance, Pergamon Press, Oxford (1982).

4. V. A. Baum and R. Bairamov, ?Heat and Mass Transfer Processes in Solar Stills of Hotbox Type?, Int. J. Solar Energy, Vol. 8, Issue. 3, pp.78-82, 1964.

5. A.A. Al-Karaghouli and W.E. Alnaser, ?Experimental Comparative Study of the Performances of Single and Double Basin Solar-Stills?, Applied Energy, Vol.77, pp. 317–325, 2004.

6. Ahmed Omri, Jamel Orfi and Sassi Ben Nasrallah, ?Natural Convection Effects in Solar Stills?, Desalination, Vol. 183, pp. 173-178, 2005.

7. M. Boukar and A. Harmim, ?Parametric Studies of a Vertical Solar Still under Desert Climatic Conditions?, Desalination, Vol. 168, pp. 21–28, 2004.

8. A.M. El-Nashar, ?The Economic Feasibility of Small SolarMED Seawater Desalination Plants for Remote Arid Areas?, Desalination, Vol. 134, pp. 173–186, 2001.

9. Salah Abdallah, Omar Badran and Mazen M. Abu-Khader, ?Performance Evaluation of a Modified Design of a Single Slope Solar Still?, Desalination, Vol. 219, pp. 222–230, 2008.

10. R.V. Dunkle, ?Solar Water Distillation: Roof Type Still and a Multiple Effect Diffusion Still?, International Development in Heat Transfer, A.S.M.E., Proc. International Heat Transfer, Part V, University of Colorado, pp. 895, 1961.

11. S. Adhikari, Ashvini kumar and G.D. Sootha, ?Simulation Studies on a MultiStage Staked Solar Still?, Solar Energy, Vol. 54, No. 5, pp. 317 – 325, 1995.

12. M.A.S. Malik, G.N. Tiwari, A. Kumar and M.S. Sodha, ?Solar Desalination?, Pergamon Press, New York, U.S.A, 1982.

13. J.A. Duffie and W.A. Beckman, ?Solar Energy Thermal Process?, John Wiley and Sons, New York, U.S.A, 1974.

14. S. Tayoma, T. Aragoki, K. Murase and T. Sumura, ?Simulation of a Multi-Effect Solar Distillers?, Desalination, Vol. 45, pp. 101 – 108, 1983.

15. D.B. Brooker, F.W. Bakker-Arkma and C.W. Hall, ?Drying Cereal Grain?, AVI West Port, U.S.A, 1978.

|

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License