IJCRR - 4(9), May, 2012

Pages: 143-147

Date of Publication: 17-May-2012

Print Article

Download XML Download PDF

PHASE ANALYSIS OF NI-MN-SN FERROMAGNETIC SHAPE MEMORY ALLOYS

Author: Ajit Behera, Jyoti Prakash Dhal, Patitapabana Parida, S.C Mishra

Category: Technology

Abstract:Ferromagnetic shape memory alloys (FSMAs) are the novel materials exhibiting shape memory effect (SME) and magnetism simultaneously. They show magnetic field-induced strains at room temperature greater than any electrostrictive, magnetostrictive or piezoelectric material, and faster frequency responsethan temperature driven shape memory alloys. Among various FSMA materials, Ni-Mn-X (X =Ga, In, Sn, Sb) have gained considerable interest due to their multifunctional properties such as shape memory effect, magnetocaloric effect, magnetoresistance, etc., associated with first order martensite to austenite structural transition. FSMA spread its application in broad area from aerospace industry to medical application, but not vividly use; because of its high cost. Ni-Mn-Sn FSMAs shows low cost of manufacturing due to its low value of constituting elements. This paper investigates the behavior of Ni- Mn-Sn Heusler FSMA by varying the weight percentage of Sn. Three alloys i.e. Mn50Ni50-xSnx (x = 5, 7.5, and 10) were produced as bulk polycrystalline ingots by arc melting. In order to identify structural phases X-ray diffraction (XRD) measurements were conducted at room temperature using Cu K\a radiation. By Differential Scanning Calorimetric (DSC) study it is found that, the transformation temperatures gradually decreases as increasing the Sn content, which shows it can apply in higher working temperature range than that of Ga-FSMAs.

Keywords: Ferromagnetic Shape Memory Alloys (FSMAs); Ni-Mn-Sn; martensitic transformation.

Full Text:

INTRODUCTION

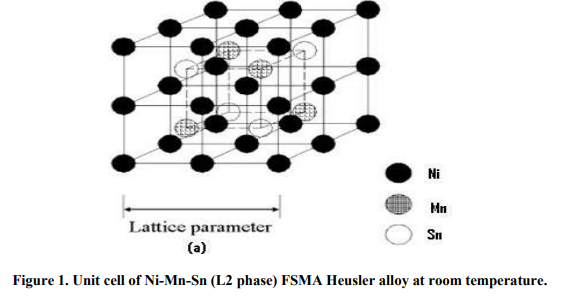

Ferromagnetic shape memory alloys (FSMAs) are the demanding material for magnetic actuator since one can obtain large reversible strains either through martensitic transformation or rearrangement of martensite variants induced by an external magnetic field. A Ni-Mn-Sn Heusler alloy has been found to undergo martensitic transformation at low temperature and the martensite phase has been found to have thermoelastic nature1 . Thermoelastic martensite phase of Ni-Mn-Sn Heusler alloy has been recently shown to be capable of magnetic shape memory effect2-3 . The magnetic field-induced strain observed in these magnetic shape memory alloys differs from conventional magnetostriction involving distortion of the crystal lattice. Magnetic shape memory effect in these materials involves the movement of twin boundaries which results in the growth of one of the twin variants at the expense of the other in response to an applied magnetic field below the martensitic transformation temperature. The crystal structure of Ni-Mn-Ga at high temperature phase (austenite) is L2 with a cubic lattice, as shown in Figure-1. This stoichiometric phase undergoes a martensitic transformation at around 276 K. This diffusionless transformation results in a martensite phase with a tetragonal structure and the transformation is reversible2 . A martensitic phase generally accommodates the strain associated with the transformation by slip or by a formation of twin variants that pack together in compatible orientations to minimize strain energy between the martensitic region and the surrounding untransformed, highly symmetric parent phase. In recent study Mn- based Heusler alloys have been focus as one of the typical magnetocaloric effect material. Among them, it is found that NiMn-Sn SMA is a less cost material due to lesser cost of Sn element. By considering cost, the goal of this investigation is to find a magnetic alloy exhibiting a martensitic phase transformation that would provide a large controllable displacement with the application of low magnetic field at reasonable operating temperature. In many experiment Ni-Mn-Ga alloys are widely examined for which it serves as a reference alloy. But the Husler alloys the choice of Ni-Mn-Sn alloy is due to: (a) Ni-MnSn not expensive as gallium, (b) It does not contain toxic as that of gallium4 , (c) Ni-Mn-Sn is less brittle than Ni-Mn-Ga5 , (d) Low transformation and curie temperature of stoichiometric Ni-Mn-Ga than Ni-Mn-Sn, (e) The austenite and martensite phase of Ni-Mn-Sn have the same crystal structure as the corresponding phases of Ni-Mn-Ga and have the same magnetically easy axis6 , (f) Ni-Mn-Sn alloys are known to have comparably high L21/ tetragonal transition temperature as that of NiMn-Ga, (g) Stoichiometric of Ni-Mn-Sn alloys reveals similar magnetostrictive behavior with respect to temperature as that of Ni-Mn-Ga alloys6 , (h) Ni-Mn-Ga alloys is insufficient for FSMA actuators7 .

MATERIALS AND METHOD

Three ternary intermetallic polycrystalline compound of composition Ni50Mn50-xSnx (x = 5, 7.5 and 10) FSMAs Heusler alloy was prepared by non-consumable arc-melting. The commercial purity of used Ni, Mn, Sn are 99.95%, 99.9% and 99.99% respectively. The melting was carried out under high purity

atmosphere (99.996%). For the preparation of alloy ingot, the melting chamber was evacuated to a pressure about 10-5 torr and then was purged with pure argon. The process of evacuation and purging was repeated up to three times. The melting was carried out in an argon atmosphere and at a chamber pressure of nearly 500Mtorr. For complete homogenization of the alloy, the entire melting process was repeated several times. Then the alloy was cast into a rod form shown in Figure 2. The ingot was sealed in a quartz ampoule filled with helium gas and solutionized at 10000C for 24 hour for homogenization. The Martensitic Transformation and phase in these alloys successfully characterized by using X-Ray Diffraction and Differential Scanning Calorimetry (DSC) DSC carried out in Mettler device working with a liquid nitrogen cooling system. I Cu-Ka radiation (k=1.5418A°) used and was carried out in the interval 30º≤2? ≤ 75º with a step increment of 0.05º.

RESULTS AND DISCUSSION

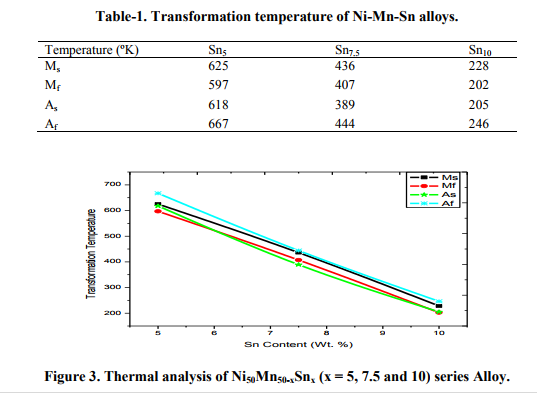

Thermal analysis: The transformation temperatures the alloy series Ni50Mn50-xSnx (x = 5, 7.5 and 10) have been determined from DSC. In forward martensitic transformation, Martensitic start temperature (Ms) and Martensite finish temperature (Mf) are measured. Simultaneously in reverse martensitic transformation Austenite start temperature (As) and Austenite finish temperature (Af) are measured. Ms , Mf , As and Af temperature of prepared alloy are given in Table-1. The transition temperatures of these alloys are plotted in the diagrams of figure-3. It is observed that Ms, Mf, As and Af decreases almost linearly by increasing the weight percent of Sn in the prepared alloy.

XRD analysis:

To determine the thermal analysis conditions it is important the knowledge of crystal structure at room temperature. So, XRD patterns were collected at room temperature by taking Cu-Ka radiation (k=1.5418A). XRD pattern of Sn5, Sn7.5, Sn10 are given in Figure-4, 5 & 6. Miller indexes were assigned by using Philips-X‘pertHighscore and JCPDF Software. For Sn5 alloy, the crystalline structure is Orthorhombic having lattice parameter a=0.7888nm, b=0.5383nm and c=0.5143. For Sn7.5 alloy, the crystalline structure is Orthorhombic and having lattice parameter a=0.7862nm, b=0.5379nm & c=0.5117nm. For Sn10 alloy, the crystalline structure is L21, which shows austenitic phase and its lattice parameter, a=0.5997nm. In Sn5 & Sn7.5 alloys the phase is found orthorhombic, but their relative peaks intensity is different. It is known that Heusler alloys sometimes present texture effects8 . In Sn10 alloy, the peaks reflections indexed as 3 1 1 and 3 3 1 confirms the existence of the highly ordered L21 structure. From XRD diffraction patterns it is clear that DSC scans of alloys Sn5 and Sn7.5 should be performed by heating from room temperature in order to detect the martensite-austenite transition. Similarly, DSC scan of alloy Sn10 should be performed by cooling from room temperature.

CONCLUSIONS

For Ni50Mn50-xSnx (x = 5, 7.5 and 10) series Alloy, as the Sn content increases from 5 to 10, the transformation temperature from martensite to austenite decreases. From X-Ray analysis, the alloys with Sn5 and Sn7.5 has orthorhombic martensite phase whereas alloy with Sn10 has a Martensite cubic L21 phase.

ACKNOWLEDGEMENT

Authors acknowledge the immense help received from the scholars whose articles are cited and included in references of this manuscript. The authors are also grateful to authors /editors / publishers of all those articles, journals and books from where the literature for this article has been reviewed and discussed.

References:

1. P. J.Webster, K. R. A. Ziebeck, S. L. Town, and M. S. Peak, ?Magnetic order and phase transformation in Ni2MnGa,? Philos. Mag., vol. 49B, pp. 295-310, 1984.

2. K. Ullakko, J. K. Huang, C. Kantner, R. C. O‘handley, and V. V. Kokorin, ?Large magnetic-field-induced strains in Ni MnGa single crystals,? J. Appl. Phys. Lett., vol. 69, 1966-1968, 1996.

3. K. Ullakko, J. K. Huang, V. V. Kokorin, and R. C. O‘handley, ?Magnetically controlled shape memory effect in Ni MnGa intermetallics,? Scrip. Metall., vol. 36, 1133- 1138, 1997.

4. S. Chatterjee, S. Giri, S. K. De and S. Majumdar, ?Magnetic Investigations on NiMn-Sn Ferromagnetic Shape MemoryAlloy?, Advanced Materials Research Vol. 52, 215-220, 2008.

5. P. J. Brown, A P Gandy, K Ishida, R Kainuma, T Kanomata et. al., The magnetic and structural properties of the magnetic shape memory compound Ni2Mn1.44Sn0.56, J. Phys.: Condens. Matter 18-2249, 2006, doi:10.1088/0953-8984/18/7/012.

6. Byung Sang Choi, ?Thermal, Magnetic and Magnetoelastic data on three different Heusler alloys based on Ni-Mn-X (X=Ga, In or Sn)?, IEEE Transaction on Magnetic, vol.42, no.7, 1770-1777, July 2006.

7. Y.Sutou, Y. Imano, N. Koeda, T. Omori, R. Kainuma et.al. ?Magnetic and martensitic transformations of NiMnX(X=In,Sn,Sb) ferromagnetic shape memory alloys?, volume 85, number 19, 4358-4360, 2004, doi: 10.1063/1.1808879.

8. Sanchez-Llamazares JL, Sanchez T, Santos JD, Perez MJ, Sanchez ML, Hernando B, et al. ?Martensitic phase transformation in rapidly solidified Mn50Ni40In10 alloy

|

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License