IJCRR - 4(13), July, 2012

Pages: 48-55

Date of Publication: 18-Jul-2012

Print Article

Download XML Download PDF

AUTOMOTIVE EMISSION OF BIO FUEL - A REVIEW

Author: Shailendra Singh, Alok Choube

Category: Technology

Abstract:Among several alternative for conventional automotive fuels, bio fuel is catching lot of attention due to its availability and emission characteristics. This review paper discussed about the comparative engine performance and emission characteristics of bio fuel and conventional fuel assist by several researchers. The bio fuel used in the form of various bio fuel such as ethanol, Jatropha, Mahua oil, Biodiesel, pongamia pinnata methyl ester (PPME), vegetable oil. Several bio fuel used as bio diesel.

Keywords: Eco friendly, low cost and easily availability of bio fuel.

Full Text:

INTRODUCTION

The world is presently confronted with the twin crises of fossil fuel depletion and environmental degradation. Indiscriminate and lavish consumption of fossil fuels have led to reduction in underground-based carbon resources. The search for alternative fuels, which promise a harmonious correlation with sustainable development, energy conservation, efficiency and environmental preservation, has become highly pronounced in the present context. [4]. Emissions from combustion engines have a considerable impact on the environment and human health In order to reduce emissions, a wide range of alternative fuels are being developed [12]. Diesel engines are the most efficient prime movers. From the point of view of protecting global environment and concerns for long-term energy security, it becomes necessary to develop alternative fuels [5] Global air-pollution is a serious problem. Much of this pollution is caused by the use of fossil fuels for transportation [13]. The fuel of bio-origin can provide a feasible solution to this world wide petroleum crisis. Gasoline and diesel driven automobiles are the major sources of greenhouse gases (GHG) emission. Scientists around the world have explored several alternative energy resources, which have the potential to quench the everincreasing energy thirst of today‘s population. Various bio fuels energy resources explored including biomass, biogas, primary alcohols, vegetable oils, biodiesel etc. These alternative energy resources are largely environment-friendly but they need to be evaluated on case to case basis for their advantages, disadvantages and specific applications. Some of these fuels can be used directly while other needs to be formulated to bring the relevant properties closer to conventional fuels [4]. Biodiesel is 100% renewable only when the alcohol used in the transesterification process is also renewable, but this proportion is reduced to around 90% (if the balance is made in mass) or 95 %( if the balance is made in carbon mass) when fossil alcohol (usually methanol) is used [11]. It is important for an alternative diesel fuels to be technically acceptable, economically competitive, environmentally acceptable and easily available. Among these alternative fuels, biodiesel and its derivatives, have received much attention in recent years for diesel engines. Biodiesel is an oxygenated diesel engine fuel that can be obtained from vegetable oils or animal fats by conversion of the triglycerides to esters via transesterification. [8]

Energy Scenario

The present energy scenario has simulated active research interest in non-petroleum, renewable and non-pollutant fuels. The world reserves of primary energy and raw materials are very limited. According to an estimate, the reserves will last for 218 years for coal, 41 year for oil, and 63 year for natural gas. The enormous growth of world population, increased technical development and standard of living in the industrial nations has led to this intricate situation in the field of energy supply and demand. The prices of crude oil increasing and fluctuating on a daily basis. This necessitates developing and commercializing fossil fuel alternatives from bio origin. Use of fossil fuels such as petroleum product and coal lead to several environmental problems such as reduction in underground-based carbon energy sources, serious modifications in earth‘s surface layer. Usage of these fossil fuels has led to increase in CO2 level in atmosphere from 280PPM in pre industrial era to 350 PPM now. These CO2 level are still climbing as a function of fuel burnt leading to green house effect, acid rains, smoke and change of climate world over [4]

It has been reported by the results of many studies that biodiesel can be used in diesel engines with little or no modifications and with almost the same performance. Besides it reduces carbon monoxide (CO), unburned hydrocarbons (HC), and smoke emissions. [8]

Alternative of Diesel (Petroleum Product)

Ethanol India is the fourth largest ethanol producer after Brazil, the United States and China, its average annual ethanol output amounting to 1,900 million litres with a distillation capacity of 2,900 million litres per year. For a 5 percent ethanol blend in petrol nationally, the ethanol required would be 640 million litres of ethanol in 2006-2007 and 810 million litres in 2011-2012. Current capacity can potentially satisfy this demand. The cost of ethanol production can be decreased by using improved agricultural practices to increase sugarcane yield and deploying energyefficient ethanol dehydration methods like pressure-swing adsorption and membrane separation. Restrictive government policies need to be reformed to loosen constraints on ethanol production.

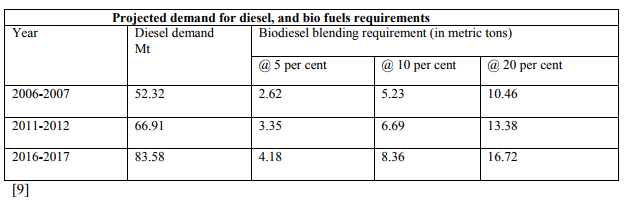

India is now the world‘s largest sugar consumer and this has put added pressure on the ethanol industry. As agricultural research has amply demonstrated, sweet sorghum and tropical sugar beet are cost-effective feedstock crops that may substitute for sugarcane. Furthermore, exciting new biotechnology involving enzymatic saccharification and fermentation has made it possible to use readily available cellulosic material like wood and crop residue for ethanol production. Also, trade in ethanol can play an important part in helping meet India‘s ethanol requirements. India‘s trade policies do not have to be protectionist, but should rather be aimed at spurring domestic growth [9]. Commercial diesel fuel, 20% biodiesel and 80% diesel fuel, called B20, and 80% biodiesel and 20% ethanol, called BE20, were used in a single cylinder, four strokes direct injection diesel engine. The effect of test fuels on engine torque, power, BSFC, brake thermal efficiency, exhaust gas temperature, and CO, CO2, NOx and SO2 emissions was investigated. The experimental results showed that the performance of CI engine was improved with the use of the BE20 especially in comparison to B20. Besides, the exhaust emissions for BE20 were fairly reduced [8]. Biodiesel and petroleum diesel have similar properties, hence, nearly all conventional diesel engines is able to work fueled without any modification with blends from pure diesel up to B20 [14]. Jatropha The Government of India has developed an ambitious National Biodiesel Mission to meet 20 per cent of the country‘s diesel requirements by 2011-2012. Since the demand for edible vegetable oil exceeds supply, the Government decided to use non-edible oil from Jatropha Curcas oilseeds as biodiesel feedstock [9]. The effect of reducing Jatropha oil‘s viscosity by increasing the fuel temperature (using waste heat of the exhaust gases) and thereby eliminating its effect on combustion and emission characteristics of the engine [5]. The performance and emissions tests were conducted with diesel, preheated Jatropha oil, unheated Jatropha oil and blends of Jatropha oil at different loads and constant speed (1500 rpm). From the experimental results obtained, Jatropha oil is found to be a promising alternative fuel for compression ignition engines [5]. Compared to neat diesel operation, methyl esters of Honge oil, Jatropha and sesame oils result in poor performance associated with higher emissions [15]. Mahua Oil Mahua oil (crude) is widely available in India and neighboring countries. Furthermore, the use of non-edible vegetable oils such as Mahua oil is of significance because of the great need for edible oil as food. It is well established that for alkali hydrolysis, the raw vegetable oil has to meet certain specifications. In experimental investigation, Mahua Oil Ethyl Ester (MOEE) was prepared by transesterification using H2SO4 as a catalyst and tested in a 4-stroke direct injection natural aspirated diesel engine. It was observed that properties of MOEE were similar to standard diesel. [16]. Tranesterification, or alcoholysis, is the reaction of a fat or oil with an alcohol to form esters and glycerol. The literature clearly shows that transesterification is the best way to use vegetable oil as a fuel in existing diesel engine [7]. Biodiesel Global air-pollution is a serious problem. Much of this pollution is caused by the use of fossil fuels for transportation. Therefore, engine manufacturers have designed alternatively fueled engines and fuel systems, which provide sufficient power while staying within regulatory emissionlimits. At the same time, a great deal of research and development on internal-combustion engines has taken place not only in the design area but also in finding an appropriate fuel. Many researchers have concluded that biodiesel holds promise as an alternative fuel for diesel engines. Diesel-fuel blends with biodiesel have superior lubricity, which reduces wear and tear on the diesel engine and makes the engine components last longer. Biodiesel mixes well with diesel fuel and stays blended. These characteristics of biodiesel reduce the emissions of carbon monoxide (CO), hydrocarbons (HC), and particulate matter (PM) in the exhaust gas compared with diesel fuel [1, 2, 9]. Exhaust gas recirculation (EGR) is effective to reduce NOx from diesel engines because it lowers the flame temperature and the oxygen concentration in the combustion chamber. However, EGR results in higher particulate matter (PM) emissions. Thus, the drawback of higher NOx emissions while using biodiesel may be overcome by employing EGR [6].

Pongamia Pinnata Methyl Ester (PPME)

Pongamia pinnata is a non-edible species capable of growing in almost all types of land (sandy, rocky including oolitic limestone). It grows even in salt water and can withstand extreme weather conditions with a temperature range of 0–500C and annual rainfall of 5–25 dm. Transesterification of pongamia oil was carried out by heating of oil, addition of KOH and methyl alcohol, stirring of mixture, separation of glycerol, washing with distilled water and heating for removal of water. The PPME so produced was mixed with diesel in varying proportions from 20% to 100% by volume (B20, B40, B60, B80 and B100) with the help of a magnetic stirrer. The blends were stirred continuously to achieve stable property values. Fuel properties such as flash point, fire point, kinematic viscosity and calorific value were determined for PPME and are compared with the other biodiesel. From the experimental investigation, it is concluded that blends of PPME with diesel up to 40% by volume (B40) could replace the diesel for diesel engine applications for getting less emissions and better performance and will thus help in achieving energy economy, environmental protection and rural economic development. In the near future conventional fuels will be fully replaced by biodiesel and will provide a viable solution for the much threatening environmental pollution problems [10]. Vegetable Oil Bio-diesel, which can be used as an alternative diesel fuel, is made from renewable biological sources such as vegetable oil and animal fats. It is biodegradable, non-toxic and possesses low emission profiles. Also, the uses ofbio-f uels are environmentally beneficial [3].

LITERATURE REVIEW

Huseyin Aydin, Cumali Ilkilic (2010) has used higher percentage of bio diesel in unmodified diesel engine, 20% bio diesel and 80% diesel fuel called as B20, and 80% bio diesel and 20% ethanol is called BE20. On investigation they found that performance increases as well as the Percentage level of CO2, CO, HC, NOX, SOX get decreased. K. Sureshkumar, R. Velraj R. Ganasan (2008) has used Pongamia pinnata methyl ester and its blend with diesel in the proportion of B20, B40, B60, B80, B100. The Brake Specific Fuel Consumption (BSFC) is lower than diesel and for B40,BSFC is less as well as the Percentage level of CO2, CO, HC, NOX, SOX get decreased. And also said that B40 can replace diesel for better performance and less emission. Deepak Agarwal, Avinash Kumar Agarwal (2007) has used JATROPHA oil in the proportion as J10, J20, J50, J75 and J100, in which J20 is having the better result then diesel in terms of thermal efficiency, BSFC and less emission. Avinash Kumar Agarwal (2006) has used alcohol and biodiesel in CI engine. On experimental investigation the results are better for biodiesel in comparisons to diesel in terms of performance and exhaust emission. Deepak Agarwal, Shailendra Sinha, Avinash Kumar Agarwal (2006) has done experimental investigation of control of NOX emission in bio diesel fueled CI Engine, and with the help of Exhaust gas recirculator (EGR) . by using biodiesel in various proportion give the good result then diesel. Mustafa Canakei, Ahmet Erdil, Erol Areaklioglu (2005) has compaired the performance and emission, then get the results in the favour ofbiodiesel. Sukumar Puhan, N. Vedaraman, G. Sankarayanan, Bopanna V. Bharat Ram(2004) performance and emission study is based on Mahua oil the performance level in terms of thermal efficiency increases as well aw BSFC and exhaust emission was less. Joseph B. Gonsalves (2006). On the basis of Emission, various alternative fuels which are easily available in India studied.

Benefits from the use of biofuels in india Reduced emission of harmful pollutant

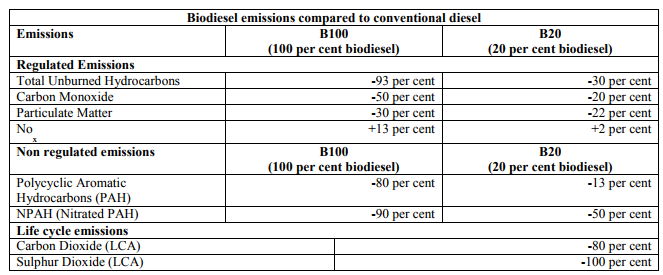

Ethanol and biodiesel are both oxygenated compounds containing no sulphur. These fuels do not produce sulphur oxides, which lead to acid rain formation. Sulphur is removed from petrol and diesel by a process called hydrodesulphurization. The hydro-desulphurization of diesel causes a loss in lubricity, which has to be rectified by introducing an additive. Biodiesel has natural lubricity, and thus no lubricity-enhancing additive is required [6,8,9]. Since ethanol and biodiesel contain oxygen, the amount of carbon monoxide (CO) and unburnt hydrocarbons in the exhaust is reduced. With the introduction of ethanol in Brazil, CO emission from automobiles decreased from 50 g/km in 1980 to 5.8 g/km in 1995. The emission of nitrogen oxides (NoX) from bio fuels is slightly greater when compared to petroleum, but this problem can be ameliorated by using de-Nox catalysts which work well with biofuels due to the absence of sulphur [6,9]. One of the disadvantages in using pure ethanol is that aldehyde emissions are higher than those of gasoline, but it must be observed that these aldehyde emissions are predominantly acetaldehydes. Acetaldehydes emissions generate less adverse health effects when compared to formaldehydes emitted from gasoline engines. Table below shows the results of the emission tests for pure biodiesel (B100) and 20 per cent biodiesel blend (B20) compared to conventional diesel [9].

The NOx emissions were slightly increased with the use of both biodiesel–ethanol blend and standard diesel fuel with respect to those of the biodiesel–diesel blend [8].

Reduction in greenhouse gas emissions

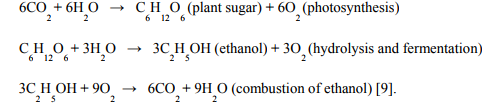

The net CO 2 emission of burning a biofuel like ethanol is zero since the CO 2 emitted on combustion is equal to that absorbed from the atmosphere by photosynthesis during the growth of the plant (sugarcane) used to manufacture ethanol. This is illustrated by the following equations:

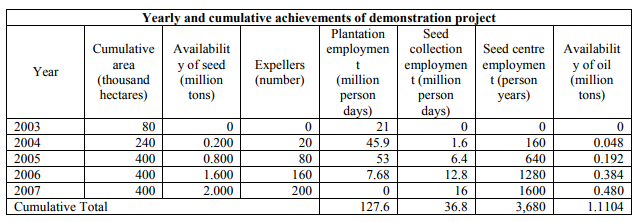

Increased Employment

At the beginning of the new millennium, 260 million people in India did not have access to a consumption basket which defines the poverty line. India is home to 22 per cent of the world‘s poor. A programmed that generates employment is therefore particularly welcome. The bio fuels sector has the potential to serve as a source of substantial employment. The investment in the ethanol industry per job created is $11,000, which is significantly less than the $220,000 per job in the petroleum field. In India, the sugar industry, which is the backbone of ethanol production, is the biggest agro industry in the country. The sugar industry is the source of the livelihood of 45 million farmers and their dependants, comprising 7.5 per cent of the rural population. Another half a million people are employed as skilled or semiskilled labourers in sugarcane cultivation. The first phase of the National Biodiesel Mission demonstration project will generate employment of 127.6 million person days in plantation by 2007. On a sustained basis, the program will create 36.8 million person days in seed collection and 3,680 person years for running the seed collection and oil-extraction centers‘. Table shows the estimated cumulative achievements of the project in terms of output and employment[9].

Improved social well-being

Improved social well-being

A large part of India‘s population, mostly in rural areas, does not have access to energy services. The enhanced use of renewable (mainly bio fuels) in rural areas is closely linked to poverty reductions because greater access to energy services can: • Improve access to pumped drinking water. Potable water can reduce hunger by allowing for cooked food (95 per cent of food needs cooking); • Reduce the time spent by women and children on basic survival activities (gathering firewood, fetching water, cooking, etc.); • Allow lighting which increases security and enables the night time use of educational media and communication at school and home; and • Reduce indoor pollution caused by firewood use, together with a reduction in deforestation. Lack of access to affordable energy services among the rural poor seriously affects their chances of benefiting from economic development and improved living standards. Women, older people and children suffer disproportionately because of their relative dependence on traditional fuels and their exposure to smoke from cooking, the main cause of respiratory diseases. Electricity through transmission lines to many rural areas is unlikely to happen in the near future, so access to modern decentralized small-scale energy technologies, particularly renewable (including bio fuels), are an important element for effective poverty alleviation policies. A programme that develops energy from raw material grown in rural areas will go a long way in providing energy security to the rural people.

CONCLUSION

The above discussed bio fuels, will play an extremely important role in meeting India‘s energy needs. Today the favorable position is this that petroleum products are costly as compare to the bio fuel. Bio fuels offer several significant benefits including:- Reduced emission of pollutants such as carbon monoxide, unburnt hydrocarbons, and particulate matter. Bio fuels contain virtually no sulphur. Reduced emission of the greenhouse gas carbon dioxide, which contributes to global warming. Increased employment. Because for the production of bio fuels several plants to be placed which require labor work. Energy security and decreased dependence on oil imports by diversification energy supply. Improved social well-being.

ACKNOWLEDGEMENT

Authors acknowledge the immense help received from the scholars whose articles are cited and included in reference of this manuscript. The authors are also grateful to authors / editors / publishers of all those articles, journals and books from where the literature for this article has been reviewed and discussed.

References:

1. Agarwal AK, Bijwe J, Das LM. Effect of biodiesel utilization on wear of vital parts in compression ignition engine. J Eng Gas Turb Power 2003;125:604–11.

2. Agarwal AK, Das LM. Biodiesel development and characterization for use as a fuel in compression ignition engines. J Eng Gas Turb Power 2001;123:440–7.

3. A.S. Ramadhas, S. Jayaraj, C. Muraleedharan Use ofvegetable oils as I.C. engine fuels—A review Renewable Energy 29 (2004) 727–742

4. Avinash kumar Agareal. Bio fuels (alcohols and biodiesel) applications as fuels for Internal combustion engines.progress in Energy and Combustion science 33 (2007) 233-271.

5. Deepak Agarwal , Avinash Kumar Agarwal. Performance and emissions characteristics of Jatropha oil (preheated and blend) in a direct injection compression ignition engine Applied Thermal Engineering 27 (2007) 2314–2323.

6. Deepak Agarwal, Shailendra Sinha, Avinash Kumar Agarwal Experimental investigation of control of NOx Emissions in biodiesel-fueled compression ignition engine Renewable Energy 31 (2006) 2356–2369.

7. Freedman B, Pryde EH, Mounts TL. Variables affecting the yields of fatty esters from transesterified vegetable oils. JAOCS 1984;61(10):1638–43.

8. Huseyin Aydin, Cumali Llkilic. Effect of ethanol blending with biodiesel on engine performance and exhaust emissions in a CI engine. Applied Thermal Engineering 30 (2010) 1199–1204.

9. Joseph B. Gonsalves. An Assessment of the Bio fuels Industry in India United Nations Conference on Trade and Development 18 October 2006.

10. K. Sureshkumar, R. Velraj, R. Ganesan Performance and exhaust emission characteristics of a CI engine fueled with Pongamia pinnata methyl ester (PPME) and its blends with diesel Renewable Energy 33 (2008) 2294–2302.

11. Mag?´n Lapuerta_, Octavio Armas, Jose´ Rodr?´guez-Ferna´ ndez Effect of biodiesel fuels on diesel engine emissions Progress in Energy and Combustion Science 34 (2008) 198–223.

12. M. Lindgren, G. Larsson, P.-A. Hansson. Evaluation of factors influencing emissions from tractors and construction equipment during realistic work operations using diesel fuel and bio-fuels as substitute journal homepage: www.elsevier.com/locate/issn/15375110

13. Mustafa Canakci, Ahmet Erdil, Erol Arcakliog?lu Performance and exhaust emissions of a biodiesel engine Applied Energy 83 (2006) 594–605.

14. N.Janardhana rao, M.R.CH.Sastry, Dr. P.Nageswara Reddy Comparative Analysis Of Performance And Emissions Of An Engine With Palm Oil Biodiesel Blends With Diesel. N.Janardhana Rao et al. / International Journal of Engineering Science and Technology (IJEST).

15. N.R. Banapurmath, P.G. Tewari, R.S. Hosmath. Performance and emission characteristics of a DI compression ignition engine operated on Honge, Jatropha and sesame oil methyl esters Renewable Energy 33 (2008) 1982–1988.

16. Sukumar Puhan, N. Vedaraman, G. Sankaranarayanan, Boppana V. Bharat Ram. Performance and emission study of Mahua oil (madhuca indica oil) ethyl ester in a 4-stroke natural aspirated direct injection diesel engine Renewable Energy 30 (2005) 1269–1278.

|

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License