IJCRR - 4(14), July, 2012

Pages: 50-55

Date of Publication: 31-Jul-2012

Print Article

Download XML Download PDF

EFFECT OF BLAST FURNACE SLAG POWDER ON COMPRESSIVE STRENGTH OF MORTAR

Author: Atul Dubey, R. Chandak, R.K.Yadav

Category: Technology

Abstract:The strength development of mortar containing blast-furnace slag and Portland cement was investigated. Mortar property can be maintained with advanced mineral admixtures such as blast furnace slag powder as partial replacement of cement 5% to 30%. Compressive strength of blast furnace slag mortar with different dosage of slag was studied as a partial replacement of cement. From the experimental investigations, it has been observed that the optimum replacement of GGBFS to cement without changing much the compressive strength is 15%.

Keywords: Mortar, Blast Furnace Slag Powder, Compressive Strength, Optimum Replacement

Full Text:

INTRODUCTION

Steel slag is a solid waste discharged in large quantities by the iron and steel industry in India. The recycling of these slags will become an important measure for the environmental protection. Iron and steel are basic materials that underpin modern civilization, and due to many years of research, the slag that is generated as a by-product in iron and steel production is now in use as a material in its own right in various sectors. Slag enjoys stable quality and properties that are difficult to obtain from natural materials and in the 21st century is gaining increasing attention as an environmentally friendly material from the perspectives of resource saving, energy conservation and CO2 reduction. The primary constituents of slag are lime (CaO) and silica (SiO2). These constituents are also contained in earth crust in general or in ordinary rocks and minerals, and their chemical composition is similar to that of regular sedimentary rock and Portland cement. CaO the primary constituent of slag is soluble in water and exhibits an alkalinity like that of cement or concrete. And as it is removed at high temperatures of 1,200°C and greater, it contains no organic matter whatsoever. This paper deals with the use of the blast furnace slag powder as a partial replacement of opc and its effect on strength of cement mortar.

Literature Review:

Throughout the long history of the iron and steel industries, ways have been sought to make effective use of these slag, but their traditional use as landfill material has been nearing its limit with the massive expansion of the steel industry since the mid-1970. The steel companies have since taken on as among their important management challenges the development of technology, the maintenance of production facilities and certification for ferrous slag products in the market in order to expand the applications of these slag,and the Japan Iron and Steel Federation (JISF) and Nippon Slag Association (NSA) have promoted the institution and widespread adoption of Japan Industrial Standards (JIS). As a result, 99% of slag is now useful material, employed by such national agencies as the Ministry of Land, Infrastructure and Transport and by local governments and other users, and it has gained both high acclaim and certification. The history of recycling ferrous slag is a long one. Production of Portland blast-furnace slag cement began in 1910, and the Japanese national standard for Portland blast-furnace slag cement (JES 29) was formulated in 1926.some of the study has been done in past which summarized as: Sun, S.S., Zhu, G.L., Zhang concluded that the recycling of steel slag will inevitably become an important measure for the environment protection and therefore will be of great significance .[1] Mineral additives are available in large quantities that can be used to replace Portland cement in concrete.[2] Few studies have been performed to determine, thermal properties, mechanical properties, transport mechanisms and the influence of mineral additions on the durability of blended concrete .[3, 4, 5, 6] Liu, Sun and Zhu found that when compound mineral admixtures with steel slag powder and blast-furnace slag powder are mixed into concrete, the performance of concrete can be improved further due to the synergistic effect and activation each other. [7, 8] Li, Yao ,Wang, Lin The high performance concrete can be produced using mineral admixture with steel slag powder and blast furnace slag so the recycling of steel slag can bring enormous benefits and environmental benefit to whole society.[9] Ground granulated blast furnace slag is commonly used in combination with Portland cement in concrete for many applications. [10,11] The heat of hydration is dependent on the Portland cement used and the activity of the GGBF slag. Roy and Idorn (1982) found a correlation of heat of hydration to strength potential of various blends of GGBF slag and Portland cement. [12] The early age strength development of mixtures containing GGBS is highly dependent on temperature. Under standard curing conditions, GGBS mortars gain strength more slowly than Portland cement mortars .[13]

Research Significance

The research reported in this study, blast furnace slag powder obtained from steel plant Bhilai is used as a cement replacement material in cement mortar paste. Optimal dosage range of this blast furnace slag powder is chosen based on cement paste studies .The ultimate focus of this work is to ascertain the performance of cement mortar containing blast furnace powder and compare it with the plain cement paste. This is expected to provide:- ? To partially replace cement content in concrete & mortar as it directly influences economy in construction. ? Environmental friendly disposal of waste steel slag. ? To boost the use of industrial waste

Material Characteristics

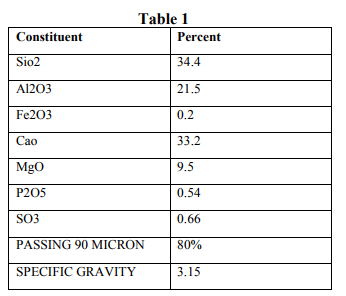

The blast furnace slag powder obtained from Bhilai steel plant used in this study has the chemical composition shown in table 1.

RESEARCH METHODOLOGY

Cement Paste Mortar:

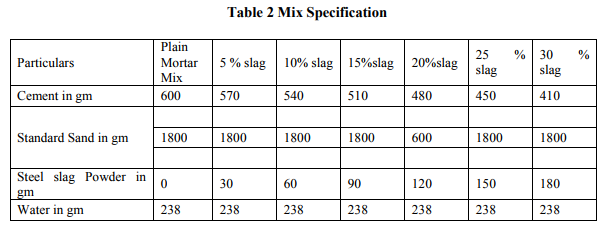

Study of compressive strength of mortar in 3,7,28 days using Blast furnace slag powder in OPC (5%to30%) mortar will be prepared as per the test procedure given in the relevant IS code .For optimal dosage selection of blast furnace slag powder the modified pastes (% ranging from 5 % to30 % Table 2.) cubes are prepared and compared with plain mix cubes. Fig (1) Depicts the compressive strengths of blast furnace slag powder modified cement pastes cured under saturated conditions for 28 days. From fig (1) it can be noticed that, at 28 days the blast furnace modified pastes show compressive strength very close to that of the plain paste, even at 20 % replacement levels. Test for Cement Mortar Strength as per I.S. 4031 Part -7 Cement used: OPC 43 grade Type of Sand used: Standard sand confirming to I.S 650- 1966 W/ c Ratio: To find water requirement added to cement normal consistency is calculated as per I.S Code 4031-1988 [(P/4+3) x total weight of sand and cement /100] where p is normal consistency of cement (27.7/4+3) x24= 238.2 say 238gm Cement: Fine Aggregate proportion used: 1: 3

TEST RESULT

TEST RESULT

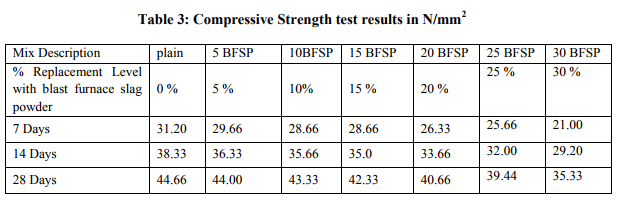

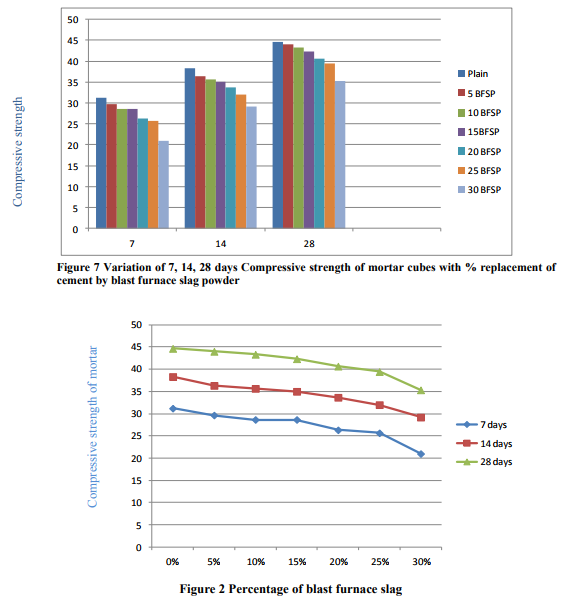

Compressive strength test was conducted to evaluate the strength development of Cement mortar paste containing various % of blast furnace slag powder at the age of 7,14,28 days respectively.

DISCUSSION AND CONCLUSION

The variation of compressive strength of mortar mix with different proportion of BFSP as a partial replacement of cement is shown in fig.1 and fig2 It was observed that 7 days and 14 days and 28 day compressive strength reduces about 25% that is from 31.25 N/mm2 to 21.00N/mm2 , 38.33N/mm2 to 29.20 N/mm2 .and 44.66 N/mm2 to 35.33 N/mm2 respectively as percentage of blast furnace slag powder increases from 0 to 30%. From study it has been found that as the % of BFSP increase, the strength tends to decrease. The main objective of this paper was to provide results of studies conducted on blast furnace slag powder modified cement mortar paste in order to ascertain the influence of blast furnace slag powder on the characteristics strength of mortar. The compressive strength test results conducted in mortar containing OPC and various percentage of BFSP is comparable to that of mortar without slag powder. On replacement of OPC with 15% blast furnace slag powder the depreciation in 28day compressive strength is being near about 5 %.

ACKNOWLEDGEMENTS

Authors acknowledge the immense help received from the scholars whose articles are cited and included in references of this manuscript. The authors are also grateful to authors /editors /publishers of all those articles, journals and books from where the literature for this article has been reviewed and discussed.

References:

1. Sun, S.S., Zhu, G.L., Zhang, Y., "ApplicationTechnology of Iron and Steel Slag in China", China Waste Steel, Vol.4, Feb., 2007, pp21-28.

2. Muha mad, I. A. K. and Emmanuel, R., "Effect of Mineral Additives on Some of Durability Parameters of Concrete", Proceeding of International Conference on Advances in Cement Based Materials and Applications in Civil Infrastructure, LahorePakistan, Dec.12-14, 2007, pp289-299.

3. Sobolev, K., "Mechano-chemical Modification of Cement with High Volumes of Blast Furnace Slag", Cement & Concrete Composites, Vol.27, 2005, pp848-853.

4. Malhotra, V. M., "Reducing CO2 EmissionsThe Role of Fly Ash and Other Supplementary Cementitious Materials", Concrete International, Vol.28, Sep., 2006, pp42-45.

5. Park, C.K., Noh, M.H. and Park, T.H., "Rheological Properties of Cementitious Materials Containing Mineral Admixtures", Cement and Concrete Research, Vol.35, 2005, pp842-849.

6. Barnett, S.J., Soutsos, M.N., Millard, S.G., Bungey, J.H., "Strength Development of Mortars Containing Ground Granulated Blast-furnace Slag: Effect of Curing Temperature and Determination of Apparent Activation Energies", Cement and Concrete Research, Vol.36, 2006, pp434-440.

7. Liu, T.C. and Yang, H.M., "Ultrafine Steel Slag and Latest Advance in Blending Materials of High-performance Concrete". Metal Mine, Vol.41, Sep., 2006, pp8-13.

8. Sun, J.Y. and Huang, C.H., "Influence of Slag and Steel Slag Composite on Properties of High Content Slag Concrete", new building materials, vol20 jul.2004,ppl3-15

9. Li, Yao, Wang, Lin effect of steel slag powder on mechanical properties of high performance concrete? 8th international symposium on utilization of high strength and high performance concrete pp628-632

10. Report of ACI committe233,slg cement in concrete and mortar,aci233r-03,American concrete institute, Farmington hills, mich 2003 11. J.Bijen, blast furnace slag cement for durable marine structures,stichingbetonprisma,Netherlands,1 996

12. Roy, D. M., and Idorn, G. M., ?Hydration, Structure, and Properties of Blast Furnace Slag Cements, Mortars, and Concrete,? Proceedings, ACI JOURNAL V. 79, No. 6, Nov.- Dec. 1983, pp. 445-457.

13. S.J. Barnett , M.N. Soutsos, S.G. Millard, J.H. Bungey Strength development of mortars containing ground granulated blast furnace slag :effect of curing temperature and determination of apparent activation energies , Cement and Concrete Research 36 (2006) 434 – 440

|

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License