IJCRR - 4(14), July, 2012

Pages: 06-10

Date of Publication: 31-Jul-2012

Print Article

Download XML Download PDF

IMPROVING QUALITIES OF OILS FROM ELAEIS GUINEENSIS SPECIES BY PROCESSING WITH NELSONIA CANESCENS LINN SPRENG (ACANTHECEAE) LEAVES

Author: Umerie, SC., Okonkwo, JC., Okorie, NH, Ibekwe BO

Category: General Sciences

Abstract:Nelsonia canescens leaves were used in the processing of palm oils to improve the quality and stability of the oils. Palm oils were obtained from the ripe fruits of Elaeis guineensis var nigrescens and Elaeis guineensis var virescens. Phytochemical analysis of Nelsonia canescens leaves and the oils were arried out. The qualities of the oils were assessed in terms of free fatty acid content, saponification, acid, and iodine values. Results showed the presence of flavonoids, saponins, \?-carotenes, tocopherols, alkaloids, tannins and glycosides in the leaves. Oils from both oil palm varieties contained little amounts of arotenoids and flavonoids. The use of Nelsonia canescens leaves removed the saponins present in var virescens oil, lowered the levels of iodine, acid and free fatty acid values, but enhanced the saponification

values in both oil varieties. In lowering iodine value unsaturation property of the oil was reduced.

Consequently rancidity tendencies of the oils were reduced. Evidently, the use of Nelsonia canescens

leaves will enhance the stability and shelf life of palm oils.

Keywords: Elaeis guineensis varieties; nigrescens and virescens, Nelsonia canescens leaves, palm oil processing and quality.

Full Text:

INTRODUCTION

Palm oils are obtained from the flesh (?mesocarp?) of the oil palm, Elaeis guineensis Jacq, fruit. The oil palm varieties Elaeis guineensis var nigrescens and E.guineensis var virescens (the African oil palm) both belong to the family Palmae, Palmaceae or Arecaceae (Mozingo, 1989), subfamily Cocoideae (Okeke, 1981). Each of the varieties has three basic types, the Dura type characterized by thin mesocarp, thick endocarp (shell) with generally large kernels, the Tenera type characterized by thick mesocarp, thin endocarp with reasonably sized kernel, and the Pisifera type characterized by thick mesocarp (with little oil content), no endocarp (shell less) with small kernels (NIFOR, 1985). The unripe fruits of E. guineensis var nigrescens appear blueblack in the bunch and dark red when ripe, while the unripe fruits of the virescens variety appear green but turn orange-red when fully ripe (Hartley, 1988). The oil of the virescens variety foams excessively on heating and this makes it distasteful for oil consumers, hence lowering its market value (Umerie et al, 2004). Palm oil contains a mixture of polyunsaturated, monounsaturated and saturated fatty acids. The relative concentrations are 38.7% oleic acid, 10.5% linoleic acid, 44.3% palmitic acid and 4.6% stearic acid (Anon., 2009). The fatty acid composition of palm oil is similar to that of the adipose tissue in most people on an ordinary diet. The greater acceptance of palm oil over other vegetable oils results from its superior properties as well as its health and nutritional values being a healthy component of human and animal diets (Onwudinjo. 2010). Palm oil and palm oil products are naturally occurring sources of the antioxidant vitamin E constituents, tocopherols and tocotrienols. These natural antioxidants acts as scavengers of damaging oxygen free radicals and one hypothesized to play a protective role in cellular aging, atherosclerosis and cancer. Carotenes and tocopherol contribute to the stability and nutritional importance of palm oil. (Goh, et al 1985). Nelsonia canescens Linn Spreng (N. canescens) belongs to the Acanthus family, Acantheceae, it has blue pussy leaves, grows annually and is native primarily to tropical areas of western central tropical Africa. The plant is a weed and abundant throughout the tropic. It is well known for its antioxidant activity and used in the traditional treatment of cardiovascular and inflammatory diseases (Oweyele et al, 2005). In processing palm oil from the fruits, fresh leaves of N. canescens are included at milling or pounding stage by the natives of some parts of south east of Nigeria to improve the quality and stability of the oil, Umerie at el (2004) have assessed the use of Ficus exasperate leaves to stabilize palm oils. In the same vein, this study therefore, investigates the efficacy of using N. cansescens leaves in processing of palm oils in order to improve and stabilize their qualities.

MATERIAL AND METHODS

Collection of the oil palms fruits and Nelsonia canescens leaves:

The fresh fruits of two palm varieties E. guineensis, var nigrescens and E. guineensis var virescens were obtained from Uke town, Anambra State, Nigeria. Both fruits were of the Tenera type, possessing thick mesocarp, thin endocarp with reasonably sized kernels. The mature leaves of N. canescens leaves were collected from surrounding bush at the Nnamdi Azikiwe University Awka, Anambra State. They were washed and used fresh.

Processing of the oil palm fruits:

Enough quantities of the fruits of the two oil palm varieties E. guineensis var nigreseens E. guineensis var virescens were weighed out separately, washed and boiled with water for 30mins. The fruits were removed from the water and each variety divided into two equal parts. To one part of each of the fruit verities, fresh leaves of N. canescens were added in the ratio 1:2 and manually pounded or digested together in a wooden mortar to separate the mesocarp from the kernel (depulping). The pounding continued until no streak of the coloured outer skin was distinguishable any more. The other remaining parts of the two varieties were similarly digested but without the Neslonia leaves. The oilladen mesocarp pulp of each of the four processed parts was partly hand pressed to obtain some oil, and the residual mass washed out in clean water and oil layer carefully skimmed off. The pressed oil and the skimmed portion were boiled to obtain clarified oils. The oils were collected and stored in four separate bottles until use.

Chemical and Phytochemical properties:

The saponification, iodine and acid values of the oils were estimated by standard procedures described by Plummer (1987), AOCS (1960) and Glasser (2008). The free fatty acid, FFA, was calculated from the relationship given by Norris (1965): 1 unit of Acid = 0.503% FFA (calculated as oleic acid). The methods of Harborne (1998) and Evans (2002) with slight modification were used in the estimation of the phytochemical constituents of the oils and the plant leaf. B-Corotenes and lycopene were determined spectrophotometrically at 445 and 472 nm respectively.

RESULTS AND DISCUSSION

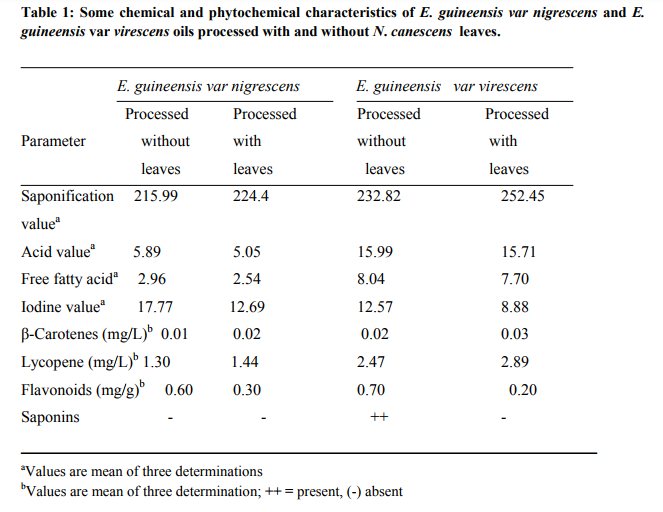

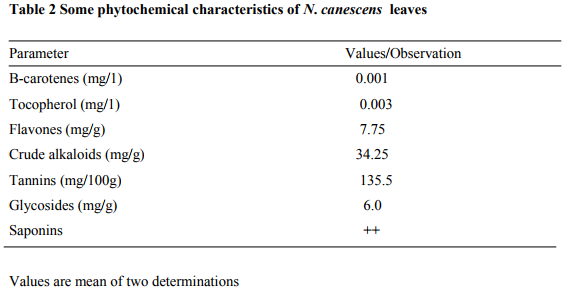

The oils obtained all appeared orange-red but those of E. guineensis var nigrescens had a deeper shade of colouration. Only the oil of E. guineesis var virescens obtained by processing without N. canescens leaves, foamed excessively when heated to effect clarification of the oils. Table 1 gives some chemical and phytochemcal characteristics of the oil samples from the two oil varieties processed with and without N. canescens leaves, while Table 2 gives some phytochemical characteristics of N. canescens leaves. The oils processed with N. canescens leaves had slightly greater saponification values, thereby making the oil better for hair relaxers, body creams, shampoos and soap production. The acid values and consequently FFA values of the oil processed with these leaves were reduced. The presence of FFA is partly attributed to the action of lipolytic enzymes at the base of the fruits which increases rapidly by 60% within an hour after detachment from the bunch (Jacobserg, 1969). The iodine value was also lowered in oils processed with N. canescens leaves due to reduction of unsaturated fatty acids present in the oil. The lower the iodine value the smaller the number of C=C double bond and thus the reduced tendency for rancidity of the oil. Consequently the oil will become more stable and possess an improved shelf life. The observed increase in saponification values (increase in saturated fatty acids) and lowered iodine values (decrease in unsaturated fatty acids) and acid values partly implicates the flavonoid, flavone. Flavonoids are potent antioxidants capable of scavenging hydroxyl radicals, superoxides anions and lipid peroxy radicals, thus keeping oxidative process in check while encouraging reductive processes (Miller, 1996; Ajali, 2004). The use of the Nelsonia leaves effected a deleting action on some of the phytochemical constituents of the oils. The saponins were completely eliminated from the oil of the virescens variety where they occur. Hence eliminating the foaming tendency of the oil as well as the danger of hemolysis of red blood corpuscles due to the presence of saponins (Lewis, 1993; McHenry, 1992). The ability of Nelsonia leaves to modify the property of the oil by eliminating the foaming factor in the virescens oil highlights the presence of anti-foaming agents in the Nelsonia leaves (Shedlovsky, 1966). The leaves have been shown to contain β-carotenes, tocopherols (vitamin E), flavonoids tannins, and glycosides, some of which could have been implicated in the sequestration and precipitation of the saponins from the virescens oil. The plant leaves, rich in carotenoids could partly account for the little increase in the levels of carotenoids in the leaf-processed oils (Table 1). Apart from antioxidant properties, studies suggest that carotenoids enhance immune function by a variety of mechanisms and improve cardiovascular health (Njoku et al, 2010). The leaf tocopherol will also enrich those of the oils thus leaf tocopherol will also add to those of the oils thus increasing the anti-oxidant activities (Ajali, 2004) within the oils.

CONCLUSION

The study has shown that palm oil processed by using N. canescens leaves have relatively improved qualities. The leaves lowered the degree of unsaturation and improved the degree of saturation. The anti-oxidant activities were enhanced while saponins, where present were eliminated. The use of N. canescens leaves have proved effective in improving the qualities of palm oils, thus justifying the use of nelsonia leaves in local palm oil processing to obtain oils of good keeping quality.

References:

1. Ajali, U. (2004). Chemistry of Bio-compounds 1 st edition Rhyce Kerex Publishers, Enugu, Nigeria.

2. Anon, (2009) Constituents of Palm Kernel. http//www. Google.com (26/08/09).

3. AOCS Official Methods, (1960). Sampling and Analysis of Commercial Fats and Oils. American Oil Chemists Society, Chicago, IL, pp 801-805.

4. Evans, W.C. (2002). Trease and Evans Pharmacognosy, 15th edition. W.B. Saunders Company Limited, Edinburgh, UK.

5. Glasser,A.C. (2008). Analysis of Fixed Oils, Fats and Waxes. In: Pharmaceutical Chemistry, Theory and Applications, Vol 1. Leslie G. Chattern (Editor). CBS Publishers and Distributor, New Delhi, India. PP 405-437.

6. Goh,S.H., Choo, Y.M. and Ong, S.H. (1985). Minor constituents of palm oil. J. Am. Oil Chemical Soc. 62 (2): 237-240.

7. Harborne, J.B. (1998). Phytochemical methods: A guide to modern techniques of plant analysis, 3 rd edition. Chapman and Hall, London, UK.

8. Hartley, C.W.S. (1988). The Oil Palm, 3rd Edition Longman Scientific and Technical Copublishers, New York.

9. Jacobsberg, B (1969). The influence of milling and storage condition on the bleachability and keepability of palm oil. In: ISP Conference on Quality and Marketing of Oil Palm Products, Kuala Lumpur.

10. Lewis, R.J. (1993) Hawley‘s Condensed Chemical Dictionary 12th Edition. Van Nostrand Reinhold Company, New York. pp. 351, 1022.

11. McHenry, R. (1992) Saponins. In: The New Encyclopedia Britannica, Micropaedia, Vol 10. Encyclopaedia Britanica Inc., Chicago. p. 442.

12. Miller, A.L. (1996) Antioxidant Flavonoids: Structure, function and clinical usage. Alternative Medicine Review 1 (2): 103 -111.

13. Mozingo, H.N. (1989) Palm In: Holland N.T. (Ed). The Encyclopaedia Americana, International edition, Vol 21. Grolier Incorporated, Danbury, Connecticut. pp. 319- 321.

14. Nigerian Institute for Oil Palm Research, NIFOR (1985). Oil Palm. In: Highlights of Activities and Achievement. Extension and Research Liaison Services Division, NIFOR, Benin City, Nigeria. pp 1 – 17.

15. Njoku, P.C., Egbukole, M.O. and Enenebeaku, C.K. (2010). Physio-chemical characteristics and dietary metal levels of oil from Elaeis guineensis species. Pakistan Journal of Nutrition 9 (2): 137-140.

16. Norris, F.A. (1995). Fats and Fatty Acids. In: Kirk-Othmer Encyclopaedia of Chemical Technology, Vol. 8 John Wiley, New York, pp. 770-881.

17. Okeke, L.P. (1987) Oil palm, In: Tropical Tree Crops Woye and Sons Ltd., Ilorin, Nigeria. pp. 251-271.

18. Onwudinjo, E.C.U. (2010) Coping with challenges of Nigeria Oil palm industry in the 21st Century. Proceeding of International Conference of Engineering Research and Development 1 (2): 18-25.

19. Oweyele, V.B., Oloriegbe, Y.Y. and Osoladoye, A. (2005) Analgesic and antiinflammatory properties of Nelsonia canescens leaf extract. J. Ethnopharmacology 99:153- 156.

20. Plummer, D.T. (1987) Quantitative analysis of lipids. In: An Introduction to Practical Biochemistry, 3rd edition. McGraw-Hill Book Company (UK) Ltd., England. pp 195-197.

21. Umerie, S.C., Ogbuagu, A.S. and Ogbuagu, J.O. (2004) Stabilization of Palm Oils by using Ficus exasperata leaves in local processing methods, Bioresource Technology 94: 307-310.

|

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License