IJCRR - 4(20), October, 2012

Pages: 198-202

Date of Publication: 20-Oct-2012

Print Article

Download XML Download PDF

EXPERIMENTAL ANALYSIS OF VARYING THE REFRIGERATION OIL PERCENTAGE IN COMPRESSOR ON THE PERFORMANCE OF VAPOUR COMPRESSION REFRIGERATION SYSTEM

Author: M. Yohan , G.Kiran Kumar

Category: Technology

Abstract:A refrigerator is a machine which attains and maintains the temperature of a space below that of surroundings by transferring heat from the space to be cooled to the surroundings with the help of a compressor. Majority of the refrigerators works on the vapor compression refrigeration system which consists of components like compressors, condensers, expansion valve and evaporator. The performance of the system depends on the performance of all the components of the system. A compressor is an important device used to raise the pressure of refrigerant to a level at which it can condense by rejecting heat to the cooling medium in the condenser. In any compressors refrigeration oil is required to prevent the friction and heat generated with in it. In general all the domestic refrigerators have hermetically sealed compressors, for these refrigerator compressors having the refrigerant R-134a and it is required good properties of refrigeration oil is required to prevent the heat generated with in the compressors. This present experimental work focus on compressor work by varying the refrigeration oil percentage on a refrigerator system capacity of 165 lts. The compressor work and performance is calculated by varying refrigeration oil percentage used in it.

Full Text:

INTRODUCTION

A compressor is a device which is used to raise the pressure of refrigerant to a level at which it can condense by rejecting heat to the cooling medium in the condenser. The compressor is an important device has to draw the refrigerant vapour from the evaporator, so that a low pressure and temperature can be maintained at which the refrigerant can boil extracting heat from the refrigerated space. The main important part of the vapour compression refrigeration system is compressor. In any compressor device piston, connecting rod, crankshaft and so many mechanical components are there. These parts are moving relative to one another. Because of these moving action the components are rubbed to each other so that friction is generated and also heat. so to prevent this heat generation lubricating oil is used . In refrigeration terminology we called refrigeration oil, with the help of refrigeration oil to prevent the heat generated with in the compressor. Generally every refrigeration oil has properties like viscosity, acidity, floc point, pour point, dielectric strength and chemical stability.. Actually these properties of refrigeration oil to effect the compressor life and performance. Generally in the domestic refrigerators have hermetically sealed compressors. In present refrigerator 1/7 HP hermetically sealed compressor is used. This paper is an experimental approach to calculate the compressor work and performance by varying the percentage of refrigeration oil. If the compressor is having low percentage of refrigeration oil the compressor parts are damaged due to more friction and heat is generated. Suppose the compressor having more percentage of refrigeration oil the suction line of the compressor is blocked due to less compression is occurred in it. Therefore proper percentage of refrigeration oil is used to run the compressor efficiently.

PRESENT WORK

The procedure for the present work is as follows. In this present experimental work a 165 lts capacity of domestic refrigerator is selected, it has 1/7 HP compressor, condenser ,expansion valve and evaporator. The work focuses to run the compressor effectively and also performance of the refrigerator system. This is only possible by providing sufficient refrigeration oil percentage used in the compressor. The rate of compressor work and performance can be increased depends on the sufficient refrigeration oil percentage used in it. The present work to find out the compressor performance and life by using and varying the refrigeration oil percentage. And also find out the optimum percentage of refrigeration oil to run the compressor efficiently. In order to know the performance characteristics of the vapor compression refrigeration system pressure and temperature gauges are installed at each entry and exit of the component. Experiments are conducted on refrigeration oil percentage in the compressor. All the values of pressures and temperatures are tabulated. The domestic refrigerator selected for the present work has the following specifications. Capacity of refrigerator - 165liters Refrigerant used - R134a Compressor - 1/7 HP Hermetically Capacity sealed. Condenser Length - 8.5m Diameter - 6.5mm Evaporator Length - 7.62m Diameter - 6.5mm Capillary tube Length - 2.128m Diameter - 0.8mm Refrigeration oil type Zed-plus lubricating oil grade-68

Where P1 = Compressor suction pressure P2 = Compressor discharge pressure P3= Condensing pressure P4= Evaporator pressure T1= Compressor suction temperature T2= Compressor discharge temperature T3= Condensing temperature T4= Evaporator temperature

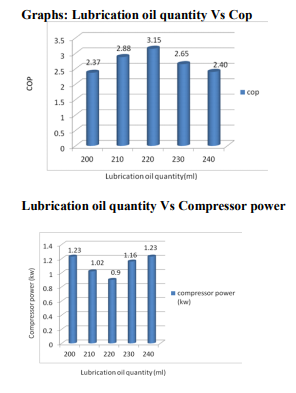

Caluclation performance parameters:- 1. Compressor work = h2-h1 2. Net refrigerating effect = h1-h4 3. Coefficient of performance(COP) COP = (h1-h4)/ (h2-h1) For Test no 1 Taken the refrigerant oil = 200ml h1= 446kJ/kg h2= 520kJ/kg h3= 270kJ/kg h4= 270kJ/kg 1. Compressor work = 520-446=74kJ/kg 2.Net refrigerating effect= 446-270=176 kJ/kg 3.Coefficient of performance(COP) COP= 176/74= 2.37 4.Theoretical compressor power=74/60=1.23kw For Test no 2 Taken the refrigerant oil = 210ml h1= 444kj/kg h2= 505kj/kg h3= 268kj/kg h4= 268kJ/kg 1. Compressor work = 505-444=61kJ/kg 2.Net refrigerating effect= 444-268=176 3.Coefficient of performance(COP) COP= 176/61 = 2.88 4.Theoretical compressor power=61/60=1.02kw For Test no 3 Taken the refrigerant oil = 220ml h1= 438 kj/kg h2= 492 kj/kg h3= 268 kj/kg h4= 268 kj/kg 1. Compressor work = 492-438= 54 kj/kg 2.Net refrigerating effect= 438-268= 170 kj/kg 3.Coefficient of performance(COP) COP = 170/54 = 3.15 4.Theoretical compressor power=54/60=0.9kw For Test no 4 Taken the refrigerant oil = 230ml h1= 452 kj/kg h2= 522 kj/kg h3= 266kj/kg h4= 266kj/kg 1. Compressor work = 522-452=70 kj/kg 2.Net refrigerating effect= 452-266=186 kj/kg 3.Coefficient of performance(COP) COP = 186/70= 2.65 4.Theoretical compressor power=70/60=1.16kw For Test no 5 Taken the refrigerant oil = 240ml h1= 452 kj/kg h2= 526 kj/kg h3= 274 kj/kg h4= 274 kj/kg 1. Compressor work = 526-452=74 kj/kg 2.Net refrigerating effect= 452-274= 178 kj/kg

3.Coefficient of performance(COP) COP= 178/74= 2.40 4.Theoretical compressor power=74/60=1.23kw

RESULTS AND CONCLUSIONS

Referring to graph 1 it is seen that the COP of Refrigerant R-134a is increased from 2.37 to 3.15 with the lubricating oil quantity from 200ml to 220ml.after that the COP is decreased from 3.15 to 2.40 with the lubricating oil quantity from 220ml to 240ml. Referring the graph 2 it is seen that the compressor power is decreased from 1.32Kw to 0.9Kw with the lubricating oil quantity from 200ml to 220ml.after that the compressor power is increased from 0.9Kw to 1.23Kw with the lubricating oil quantity from 220ml to 240ml.

The present experimental setup gives the following results

1. Cop is increased 24.87% with the lubricating oil quantity from 200ml to 220ml .

2. Compressor power is reduced 31.81% with the lubricating oil quantity from 200ml to 220ml.

References:

1. Basic Refrigeration and Air conditioning by P.N Ananthanarayana, Cremaschi L., Hwang Y., Radermacher R., 2005, Experimental investigation of oil retention in air conditioning systems, Int. J. Refrigeration, 28: 1018-1028

2. Knapp, M. H. The use of synthetic lubricants in compressor. Purdue Compressor Tech. Conf., 1972, 480-482.

3. Kedzierski M. A., 2001, The effect of lubricant concentration, miscibility, and viscosity on R134a pool boiling, Int. J. Refrigeration, 24(4): 348-366.

4. Sundaresan, S. G. and Finkenstadt, W. R. PAG and polyol ester lubricant—candidates for use with HFC-134a in refrigeration compressors. ASHRAE Conference, 1992.

5. Short, G. D. High-viscosity ester lubricants for alternative refrigerants. ASHRAE Conference, 1992

|

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License