IJCRR - 5(12), June, 2013

Pages: 125-133

Date of Publication: 28-Jun-2013

Print Article

Download XML Download PDF

EXPERIMENTAL INVESTIGATION OF PERFORMANCE AND EMISSION CHARACTERISTICS OF DIESEL ENGINE FUELED WITH LINSEED BIO DIESEL

Author: B. Madhava Varma, N. Ravi Kumar, G. Prasanthi

Category: Technology

Abstract:Industrialization, globalization & green revolution in agriculture have increased the demand for the petroleum products. Petroleum fuels release more emissions like CO, NOX, CH4 & CFC which are responsible for global warming & ozone layer depletion. Biodiesel is a less pollutant, biodegradable and renewable alternative fuel that can be used with little modifications. The objective of this study was to investigate the effect of the biodiesel produced from linseed oil on single cylinder diesel engine. Both performance and emission characteristics were studied in the range of one fourth load to full load at fixed compression ratio 16 . In the current research work biodiesel is prepared from linseed oil. The Experimentation was conducted on four stroke single cylinder diesel engine using linseed biodiesel and their performance and emission characteristics were studied. Results of performance & emission using linseed biodiesel were compared with that of diesel fuel.

Keywords: bio fuels, bsfc, emissions, global warming & linseed methyl esters

Full Text:

INTRODUCTION

Energy is an essential and vital input for economic activity. Building a strong base of energy resources is a pre-requisite for the sustainable economic and social development of a country. Indiscriminate extraction and increased consumption of fossil fuels have led to the reduction in underground-based carbon resources and release harmful emissions which is the main reason for global warming and ozone layer depletion. The depletion of world’s nonrenewable resources provided the incentives to seek alternatives to conventional, petroleumbased fuel. Due to the shortage of petroleum products and its increasing cost, efforts are on to develop alternative fuels especially, to the diesel oil for full or partial replacement. It has been found that the vegetable oils are promising fuels because their properties are similar to that of diesel. It is remembered that vegetable oils could be used as fuel for diesel engines. Studies revealed the usage of straight vegetable oil (SVO) as fuel, causes the choking of injector nozzles, piston ring sticking, crank case oil dilution, lubrication oil contamination, and other problems. The problems could be solved using the chemically treated vegetable oils called as biodiesel. Biodiesel is a biodegradable, non-toxic, sulfur free renewable fuel, it can be produced from vegetable oils and animal fats. Higher viscosity, higher molecular weight and low volatility cause poor atomization leading to incomplete combustion result in several problems. The physical and chemical properties of straight vegetable oil can be improved by transesterification and reduction in viscosity may be achieved. In general, the vegetable oils are in the form of triglycerides which are converted into esters (Biodiesel). Thus the vegetable oils are chemically subjected to a process called transesterification, in which the oil is made to react with methanol or ethanol in the presence of a base catalyst such as sodium hydroxide or potassium hydroxide which yields biodiesel. India is net importer of vegetable oils, so edible oils cannot be used for production of biodiesel. India has the potential to be a leading world producer of biodiesel, as biodiesel can be sourced and produced from non-edible oils like Jatropha, Linseed, Pongamia Pinnata, Mahua, Castor, etc. These oils are not being properly utilized. Wastelands can be used to grow these plants by multiculture which reduces global warming as plants make food by photosynthesis in which they absorb CO2. The temperature of earth is increasing at an alarming rate due to green house gases like CO2, NOx ,CH4 & CFC which are produced by using fossil fuels.

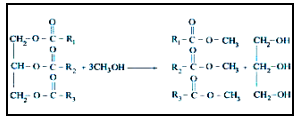

Carbon dioxide’s share in global warming is 63%. The safe limit of CO2 in environment is 270 ppm. It was around 275 ppm before 1950 but after industrialization it is icreasing rapidly and now it is around 370 ppm which led to 1º C rise in earth’s temperature. If it continuous in the same manner, CO2 will be around 550 ppm by 2100 & earth’s temperature will be raised by 4º C which causes the ice at Greenlands & Himalayas to melt and increase the sea levels. This creates major threat for coastal areas and icelands. Linseed oil is a triglyceride. It is converted into ester using transesterification reaction. The reaction requires heat and a strong catalyst (alkalis, acids, or enzymes) to achieve complete conversion of the vegetable oil into the separated esters and glycerin. The reaction is shown in below.

In transesterification reaction the triglyceride molecule of the linseed oil reacts with methanol or ethanol in the presence of a catalyst such as sodium hydroxide (NaOH). The methanol used would react with the triglyceride molecule of the linseed oil and would result in an ester (biodiesel) and glycerin (by product).One molecule of linseed oil would require three molecules of alcohol and would result in an ester and a glycerin molecule. This reaction can also be called as base catalysed transesterification reaction as the reaction would take place in the presence of a base catalyst. Jagannath et al [1] conducted performance and emission analysis on CI engine operated on waste fried oil methyl esters. They found that at higher loads the thermal efficiency of biodiesel is slightly less than that of diesel, as viscosity, volatility, atomization characteristics are lesser for biodiesel. However emissions are reduced compared to diesel. N.R. Banapurmath et al [2] investigated the performance and emission characteristics of DI compression ignition engine using Jatropha oil. They observed that the smoke opacity of the biodiesel will be higher due to their heavier molecular structure, which leads to poor atomization. Also HC emissions would be a little higher due to lesser volatility and lesser atomization. They have observed that NOX emissions were higher for diesel operation compared to biodiesels. Heat release rates of biodiesels were lower during premixed combustion phase, which will lead to lower peak temperatures. Nitrogen oxides formation strongly depends on peak temperature . Mallikappa et al [3] investigated Performance and emission characteristics of double cylinder CI engine operated with cardanol bio fuel blends. They found that brake thermal efficiency increases with increase in load due to the fact that the heat losses got reduced. Ashish Jawalkar et al [4] investigated Performance and Emission Characteristics of Mahua and Linseed Biodiesel Operated at Varying Injection Pressures on CI

Engine. They concluded that at higher loads the emissions reduced as the blend percentage of linseed biodiesel is increased. It is due to the reason that biofuels are oxygenated fuels and undergo complete combustion. A.S. Ramadhas et al [5] conducted Performance and emission evaluation of a diesel engine fueled with methyl esters of rubber seed oil and found that the specific fuel consumption is higher for biodiesel, as the calorific value of biodiesel is lesser than that of diesel. It decreases with increase in load as at higher loads complete combustion takes place and thus lesser fuel is required to produce unit power. V. Dhana raju et al [6] have done experimental investigation of linseed and neem methyl esters as biodiesel on CI engine. They have found that that mechanical efficiency in case of Diesel with LME & NME blends is similar when compared to Diesel but a slight drop of thermal efficiency was found with methyl esters (bio-diesel) when compared with diesel. This drop in thermal efficiency must be attributed to the poor combustion characteristics of methyl esters due to high viscosity. D.Lingaraju et al [7] have conducted an experiment on Diesel engine with diesel, linseed biodiesel and its blends with diesel at different injection pressures. They have found that mechanical efficiency in case of Diesel with blends is similar when compared to Diesel but a slight drop of thermal efficiency was found with methyl esters (bio-diesel) when compared with diesel. This drop in thermal efficiency must be attributed to the poor combustion characteristics of methyl esters due to high viscosity. K.Purushothamana et al [8] investigated Performance, emission and combustion characteristics of a compression ignition engine operating on neat orange oil and observed that orange oil exhibits a longer ignition delay and higher combustion duration compared to diesel. The heat release rate is higher for orange oil than the diesel. The brake thermal efficiency is maximum at full load. HC and CO emissions are reduced for orange oil compared to those of diesel. Smoke emissions are reduced marginally for orange oil than the diesel fuel. NOx emissions are higher for orange oil than the diesel. N.L. Panwar et al [9] evaluated Performance characteristics of diesel engine fuelled with methyl ester of castor seed oil and they found that exhaust temperatures increase with increase of CME in blends and is higher than that with diesel for all blends at all loads. Also a corresponding increase in NOx emission is observed. This may be due to higher combustion chamber temperature, which in turn is indicated by the prevailing exhaust gas temperature. K. Sureshkumar et al [10] investigated Performance and exhaust emission characteristics of a CI engine fuelled with Pongamia pinnata methyl ester (PPME) and its blends with diesel and found that CO2 emission increased with increase in load for all blends. The lower percentage of PPME blends emits less amount of CO2 in comparison with diesel. This is due to the fact that biodiesel in general is a low carbon fuel and has a lower elemental carbon to hydrogen ratio than diesel fuel. At higher loads, higher biodiesel (PPME) content blends emit CO2 at par with fossil diesel, in general biodiesels themselves are considered carbon neutral because, all the CO2 released during combustion had been sequestered from the atmosphere for the growth of the vegetable oil crops. Wagner et al.[11] conducted 200 h engine tests with soybean oil ester fuel on John Deere (4239T Model) engine. It was reported that the engine performance with methyl, ethyl and butyl esters was nearly same as with diesel fuel. There was no difference in thermal efficiency resulting from use of the various fuels to power the engine. The esters showed slight power loss and increased fuel consumption, which was attributed to the lower gross heating values.

PREPARATION OF LINSEED BIODIESEL

Raw vegetable oils requires certain modifications of their properties like viscosity and density before using in IC Engines. Transesterification is a process in which viscosity & density of oil can be reduced. In the transesterification of vegetable oils, a triglyceride reacts with alcohol in the presence of either acid or base catalyst to produce a mixture of fatty acid alkyl ester and glycerol. In this process Linseed oil is made to react with methanol in the presence of base catalyst(NaOH). The biodiesel is obtained from Linseed oil in the following way.

1. A 1000 ml sample of raw linseed oil is taken and is filtered and heated upto 100oC to remove water.

2. When the temperature of the oil reaches to a range of 50 - 60° C, add 120 ml of methanol and heat the oil on a magnetic stirrer for 5 more minutes and then add 3 ml of sulphuric acid (H2SO4).

3. After heating the solution for 1.5 hrs at the temperature range 50-60 °C, heating is stopped and the solution is allowed to separate into glycerin and methylester where the glycerin is settled at the bottom.

4. The settled glycerin is drained out and then oil is again purified using cotton and then base treatment is started.

5. The sample from the acid treatment is again kept for heating on a magnetic stirrer and waits till the temperature reaches to a range of 50 - 60° C. Then

6. Meanwhile methoxide solution is prepared by adding 200 ml of methanol with 5 gm of NaOH. Methoxide is added to the oil sample and heated on magnetic stirrer for 1.5 hrs at constant temperature in the range of 50-60° C.

7. After the sample, containing methoxide is heated for 1.5 hr. The sample is poured into a separating funnel.

8. Settling time of minimum 1.5 hr or more is given for the formation of glycerin left in the sample after the acid treatment and other free fatty acids which settles to the bottom of the separating funnel.

9. Then water wash is carried out in order to remove any excess glycerin or acids added during acid treatment. In this process 600 ml of water and 3 ml of phosphoric acid is added to 1000 ml of oil.

10. The oil is mixed with warter lightly and then allowed to settle in a separating funnel.

11. The water is removed and the process is repeated three times to ensure the glycerin is removed completely.

12. Finally the oil is heated to 100°C to remove any water present in the oil.

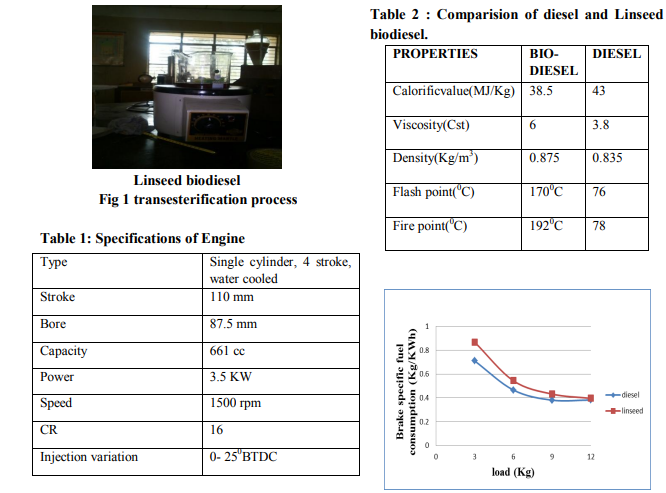

EXPERIMENTAL SETUP

The experimental setup consists of 4 stroke, single cylinder, water cooled, direct injection, vertical diesel engine on which the oil was tested. The specifications of the engine are given in table 1. A Schematic of the experimental arrangement is shown in Figure 2. Air flow was determined using air box method by measuring the pressure drop across a sharp edge orifice of the air surge chamber with the help of a manometer. The diesel flow was measured by noting the time taken for 5 cc fuel consumption. The speed of the engine was measured by help of digital tachometer. The loading is applied on the engine using eddy current dynamometer. The exhaust gas constituents HC, CO, CO2, NOx, O2 are measured using AVL DiGas 444 gas analyzer and smoke opacity was measured using AVL 437C smoke meter.

PROPERTIES OF THE BIO-DIESEL

The properties of linseed oil biodiesel were found in the fuels laboratory. The results obtained are shown in Table 2

RESULTS AND DISCUSSION

In this section we investigate the performance and emission characteristics of a high speed diesel engine at various loads from one fourth load to full load fuelled with linseed biodiesel and compared with standard diesel.

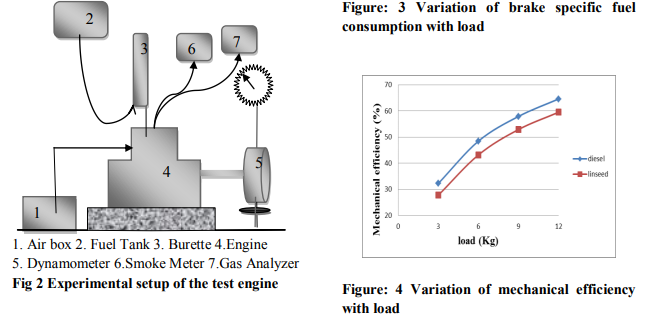

Brake Specific Fuel Consumption

Figure 3 shows the variation of specific fuel consumption with load. It is found that as load increases the brake specific fuel consumption decreases for both diesel & linsed biodiesel. This is due to the reason that at higher loads complete combustion tends to take place, thus lesser amount of fuel is required to deliver unit power. Thus bsfc decreases with increase in load. When we compare diesel and biodiesel, the specific fuel consumption is higher for biodiesel, as it has lesser calorific value than that of diesel. At part loads the increase in specific fuel consumption is 22.15% but as the load increases this value decreases and reached to 3.66% at full load.

Mechanical Efficiency

Figure 4 shows the variation of mechanical efficiency with load. It is observed from the figure that mechanical efficiency is increasing with respect to load for both biodiesel & diesel. It is clear that at any load the mechanical efficiency of diesel is higher than that of linseed oil. At part loads the increase in mechanical efficiency 16.3% but as the load increases this value decreases and reached to 8.55% at full load.

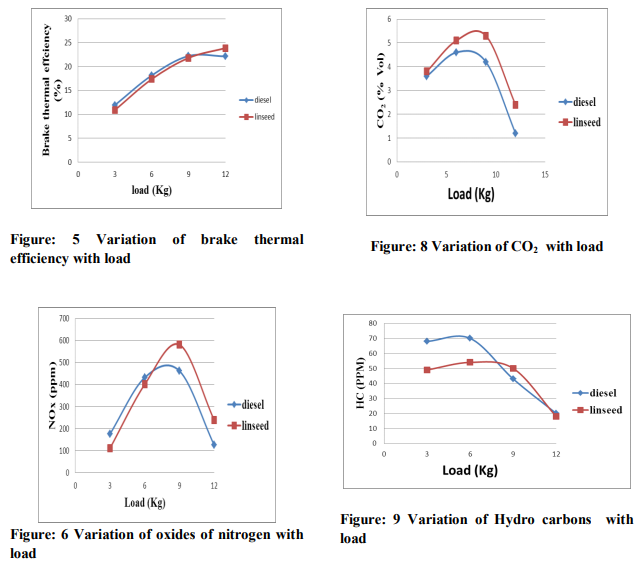

Brake thermal Efficiency

Figure 5 shows the variation of brake thermal efficiency with load. It is found that with increase in load the brake thermal efficiency is also increasing for both diesel & linseed biodiesel. It is observed that at any load condition the brake thermal efficiency of diesel is greater than that of linseed biodiesel except at full load. At part load conditions the percentage increase in brake thermal efficiency is 9.5% and it is decresing upto three fouth load and again increasing to 7.8% at full load.

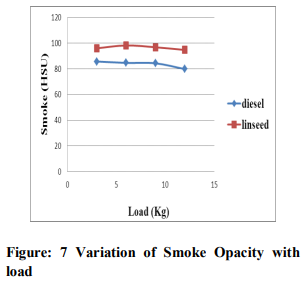

Oxides of Nitrogen

Oxides of nitrogen are the important emission in diesel engines. The oxides of nitrogen in the emissions contain nitric oxide (NO) and nitrogen dioxide (NO2). The formation of NOx is highly dependent on in-cylinder temperature and oxygen concentration. Figure 6 shows the variation of oxides of nitrogen with load. It is observed that at part loads NOx emission is higher for diesel and at three fourth & full load NOx emission is higher for linseed biodiesel. Smoke Smoke is nothing but solid soot particles suspended in exhaust gas. Figure 7 shows the variation of smoke with load. Smoke opacity varies from 85.8 HSU to 79.9 HSU for diesel operation and from 96.1HSU to 94.8 HSU for linseed biodiesel. It is observed that the smoke level for soybean biodiesel is lower than diesel at part load and full loads. The reason for the reduced smoke is the availability of premixed and homogeneous charge inside the engine well before the start of combustion. Higher combustion temperature, extended time of combustion and rapid flame propagation are the other reasons for reduced smoke Carbon Dioxide Figure 8 shows the variation of CO2 with load. It is observed that at any load emission of CO2 is higher for linseed biodiesel when compared to diesel. It is due to more availability of oxygen in case of biodiesel. It is observed that emission of CO2 is increasing initially with respect to load and decreasing gradually and reaches to minimum at full load for both diesel & biodiesel. The minimum values of CO2 at full load for both diesel & bioiesel are 1.2 % vol & 2.4 % vol.

Hydro Carbons

Figure 9 shows the variation of HC with respect to load. The emission of HC’s are increasing initially upto half load and the gradually decreasing when it reaches to full load for both diesel & linseed biodiesel. It is observed that HC emission at full load is almost same for both diesel & biodiesel.

CONCLUSIONS

conclusions are drawn from the experimentation are as follows

- Linseed Biodiesel showed high brake specific fuel consumption than that of diesel for same power developed due to its lower calorific value

- Brake thermal efficiency of diesel is greater than that of linseed biodiesel except at full load

- At any load, mechanical efficiency of diesel is higher than that of linseed oil. At part loads the increase in mechanical efficiency is 16.3% but as the load increases this value decreases and reached to 8.55% at full load.

- It is observed that at part loads NOx emission is higher for diesel and at three fourth & full loads NOx emission is higher for linseed biodiesel.

- It is observed that the smoke level for linseed biodiesel is lower than that of diesel for all loads.

- At any load emission of CO2 is higher for linseed biodiesel when compared to diesel.

- The emission of HC’s are increasing initially upto half load and then gradually decreasing when it reaches to full load for both diesel & linseed biodiesel.

Nomenclature

NME neem methyl ester

LME linseed methyl ester

CO2 carbon dioxide

CO carbon monoxide

HC hydro carbon

NOx oxides of nitrogen

CO2 carbon dioxide

HSU Hatridge smoke unit

BTDC before top dead centre

CR compression ratio

CFC chlorofloro carbon

CI compression ignition

ACKNOWLEDGEMENT

The authors are thankful to the All India Council for Technical Education (AICTE), New Delhi for their financial support under RPS scheme vide project grant by 8023/RID/RPS/041/11/12. Authors acknowledge the great help received from the scholars whose articles cited and included in references of this manuscript. The authors are also grateful to authors / editors / publishers of all those articles, journals and books from where the literature for this article has been reviewed and discussed. Authors are grateful to IJCRR editorial board members and IJCRR team of reviewers who have helped to bring quality to this manuscript.

References:

1. Jagannath Balasaheb Hirkude, Atul S. Padalkar “Performa ce and emission analysis of a compression ignition, P.G. Tewari, R.S. Hosmath “Performance and emission engine operated on waste fried oil methyl esters” Applied Energy Journal 90 (2012) 68–72.

2. N.R. Bannapurmath characteristics of a DI compression ignition engine operated on Honge, Jatropha and sesame oil methyl esters”, Renewable Energy 33 (2008) 1982– 1988.

3. Mallikappa D.N.a, Rana Pratap Reddy, Ch.S.N. Murthy “Performance and emission characteristics of double cylinder CI engine operated with cardanol bio fuel blends” Journal Renewable Energy 38 (2012) 150.

4. Ashish Jawalkar, Kalyan Mahantesh, M Jagadish, Madhusudhan Merawade, M C Navindgi “Performance and Emission Characteristics of Mahua and Linseed Biodiesel Operated at Varying Injection Pressures on CI Engine

5. A.S. Ramadhas”, International Journal of Modern Engineering Research (IJMER) Vol.2, Issue.3, May-June 2012., C. Muraleedharan, S. Jayaraj “Performance and emission evaluation of a diesel engine fueled with methyl esters of rubber seed oil” Renewable Energy 30 (2005) 1789–1800.

6. V.Dhana raju and P.Ravindra kumar “Experimental investigation of linseed and neem methyl esters as biodiesel on CI engine” International Journal of Engineering Science and Technology.

7. D.Lingaraju, S.Chiranjeeva Rao, V.Joshua Jaya Prasad, A.V.Sita Rama Raju.“Fuelling diesel engine with diesel, linseed derived biodiesel and its blends at different injection pressures: performance studies” IJMIE Volume 2, Issue 7

8. K.Purushothamana, G. Nagarajan “Performance, emission and combustion characteristics of a compression ignition engine operating on neat orange oil” Renewable Energy 34 (2009) 242–245.

9. N.L. Panwar, Hemant Y. Shrirame, N.S. Rathore, Sudhakar Jindal, A.K. Kurchania “Performance evaluation of a diesel engine fuelled with methyl ester of castor seed oil” Applied Thermal Engineering 30 (2010) 245–249.

10. K. Sureshkumar, R. Velraj, R. Ganesan “Performance and exhaust emission characteristics of a CI engine fuelled with Pongamia pinnata methyl ester (PPME) and its blends with diesel” enewable Energy 33 (2008) 2294–2302

11. Wagner LE, Clark SJ, Scrock MD. Effects of soybean oil esters on the performance, lubricating oil and wear of diesel engines. Paper No. 841385, SAE; 1984.

|

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License